Salt-tolerant ceramide liposome with skin repairing effect and preparation method of salt-tolerant ceramide liposome

A technology of ceramide lipid and ceramide, which is applied in the field of salt-tolerant ceramide liposome and its preparation, and can solve the problems of instability and liposome structure destruction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

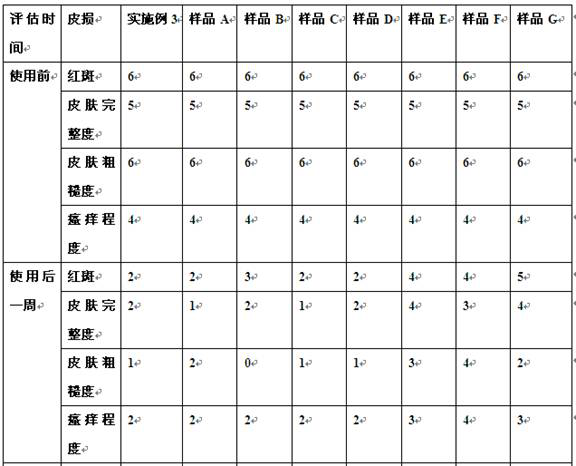

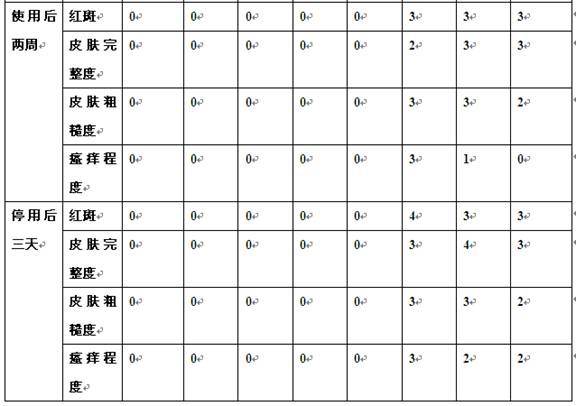

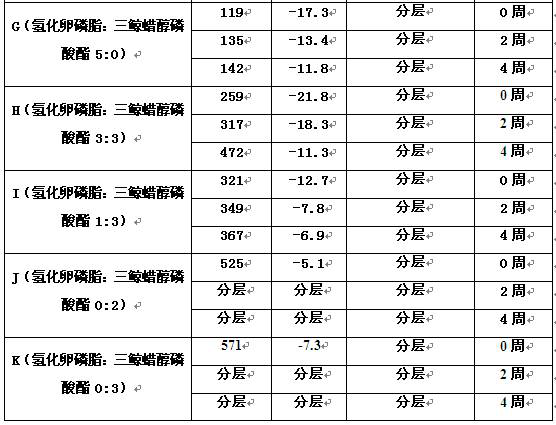

Examples

Embodiment 1

[0047] Embodiment 1: a kind of preparation method of the salt-resistant ceramide liposome with skin repairing effect, is characterized in that adopting the following steps:

[0048] A. Weigh the above 2% ceramide mixture (ceramide NP: ceramide NG: ceramide AP mass ratio is 22.1:9.2:8.9), salicyl phytosphingosine 0.01%, phytosphingosine 2% , 8% hexyldecanol, 0.5% cholesterol, 20% vegetable oil, 2% liposome membrane material (the mass ratio of hydrogenated lecithin: tricetyl phosphate is 10:0.01), heated to 75 in a stainless steel container ℃, stir with an IKA stirrer at 300rpm until completely dissolved, and this mixture is called the oil phase component;

[0049] B. Weigh the water and 60.49% polyols of the above 5% mass percentage, mix them uniformly in another stainless steel container, and heat to 75°C. This mixture is called the water phase component;

[0050] C. Mix the oil phase components obtained in step A and the water phase components obtained in step B, and use an ...

Embodiment 2

[0052] Embodiment 2: a kind of preparation method of the salt-tolerant ceramide liposome with skin repairing effect, is characterized in that adopting the following steps:

[0053] A. Weigh the above 7% ceramide mixture (ceramide NP: ceramide NG: ceramide AP mass ratio is 22.1:9.5:8.8), 0.3% salicyl phytosphingosine, 0.05% phytosphingosine , 25% hexyldecanol, 2% cholesterol, 4% vegetable oil, 5.5% liposome membrane material (the mass ratio of hydrogenated lecithin: tricetyl phosphate is 5:0.5), heated to 76 in a stainless steel container ℃, stir with an IKA stirrer at 400rpm until completely dissolved, and the mixture is called the oil phase component;

[0054] B. Weigh the water and 40.15% polyol of the above-mentioned 16% by mass percentage, mix them uniformly in another stainless steel container, and heat to 76°C. The mixture is called the water phase component;

[0055] C. Mix the oil phase components obtained in step A with the water phase components obtained in step B, ...

Embodiment 3

[0057] Embodiment 3: a kind of preparation method of the salt-resistant ceramide liposome with skin repairing effect, is characterized in that adopting the following steps:

[0058] A. Weigh the above 5.2% ceramide mixture (ceramide NP: ceramide NG: ceramide AP mass ratio is 22.1:9.5:8.5), salicyl phytosphingosine 0.5%, phytosphingosine 0.02% , 18% hexyldecanol, 1.2% cholesterol, 5% vegetable oil, 6% liposome membrane material (the mass ratio of hydrogenated lecithin: tricetyl phosphate is 3:0.2), heated to 77 in a stainless steel container ℃, stir with an IKA stirrer at 450rpm until completely dissolved, and the mixture is called the oil phase component;

[0059] B. Weigh the water and 49.08% polyol of the above-mentioned 15% by mass percentage, mix them uniformly in another stainless steel container, and heat to 77°C. The mixture is called the water phase component;

[0060] C. Mix the oil phase components obtained in step A with the water phase components obtained in step ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com