Scraped car recycling treatment device and method capable of reducing environmental pollution

A technology for scrapped cars and processing equipment, applied in chemical instruments and methods, grain processing, lighting and heating equipment, etc., can solve the problems of limited knocking effect, poor separation effect of metal and plastic, etc., and achieve the effect of improving the separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

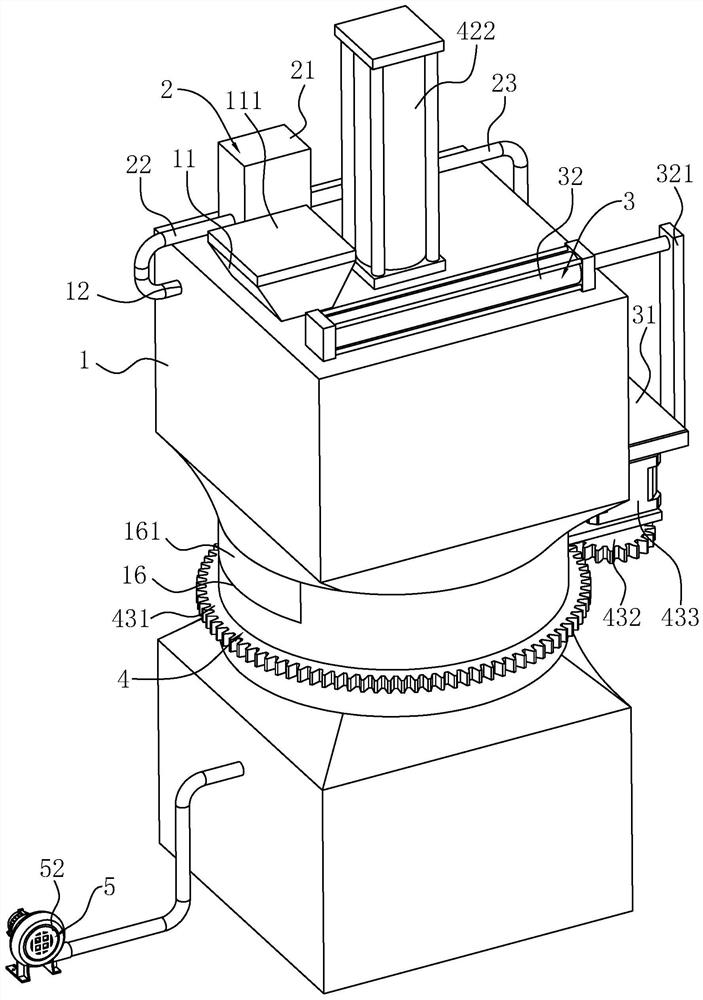

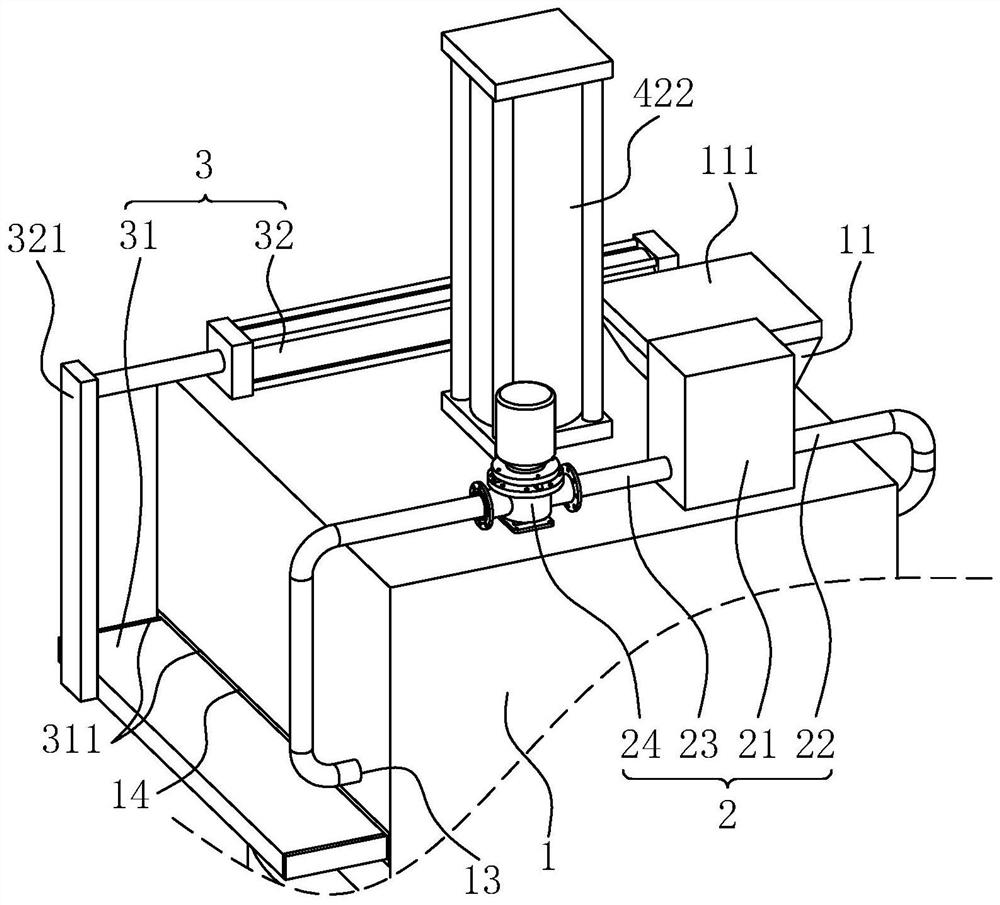

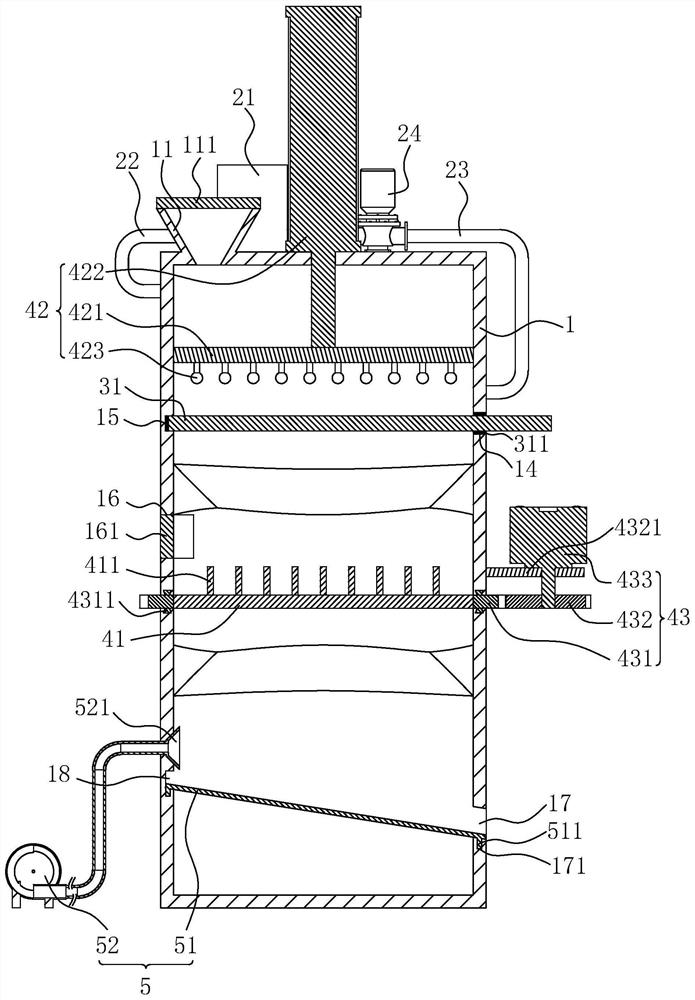

[0042] The following is attached Figure 1-5 The application is described in further detail.

[0043] The embodiment of the present application discloses a recycling treatment equipment for scrapped automobiles that reduces environmental pollution.

[0044] refer to figure 1 , a scrapped automobile resource treatment equipment for reducing environmental pollution includes a box body 1, a freezing assembly 2, a partition assembly 3, a crushing assembly 4 and a fine separation assembly 5, and the freezing assembly 2 is used for processing the scrapped automobile parts in the box body 1 Freezing treatment, the partition assembly 3 is used to divide the box body 1 into a sealed chamber during freezing, the crushing assembly 4 is used to crush the frozen scrapped automobile parts, and separate plastics from metals, and the fine separation assembly 5 is used to Further separate the metal in the plastic, so as to realize the resource separation of scrapped cars.

[0045] refer to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com