Device and method for measuring dryness of gas-liquid two-phase fluid

A measurement device, gas-liquid technology, applied in liquid/fluid solid measurement, measurement device, measurement capacity, etc., can solve the problems of bubble size phase transition and phase balance effects, easy phase transition, and difficulty in micro bubbles, etc. Fast, responsive, and low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

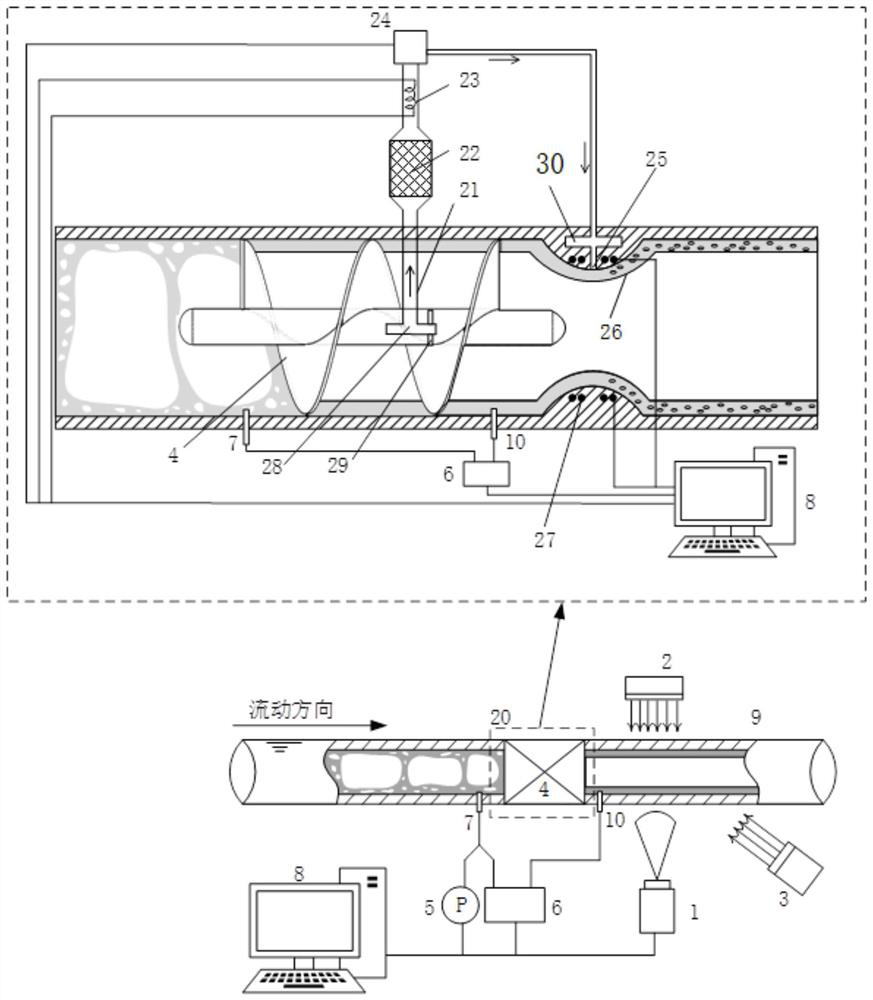

[0055] This embodiment provides a gas-liquid two-phase fluid dryness measurement device, see the attached figure 1 , including: cyclone 4, measuring tube 9, tracer bubble unit 20, image acquisition unit, pressure transmitter 5, differential pressure transmitter 6, industrial computer 8 and light source;

[0056] The outlet end of the measuring tube 9 is provided with a throat diameter section with a smaller inner diameter, and this throat diameter section is used as an accelerating nozzle 26;

[0057] The cyclone 4 is installed inside the inlet end of the measuring tube 9, that is, at the upstream end of the accelerating nozzle 26 of the measuring tube 9, and is used to make the gas-liquid two-phase fluid flow in a spiral rotation and generate a gap between the gas-liquid two-phase fluid. The separation force, so that the liquid phase moves to the tube wall of the measuring tube 9 under the action of centrifugal force, while the gas phase gathers in the central area of the t...

Embodiment 2

[0071] A method for measuring the dryness of a gas-liquid two-phase fluid based on the above measuring device, the specific steps are as follows:

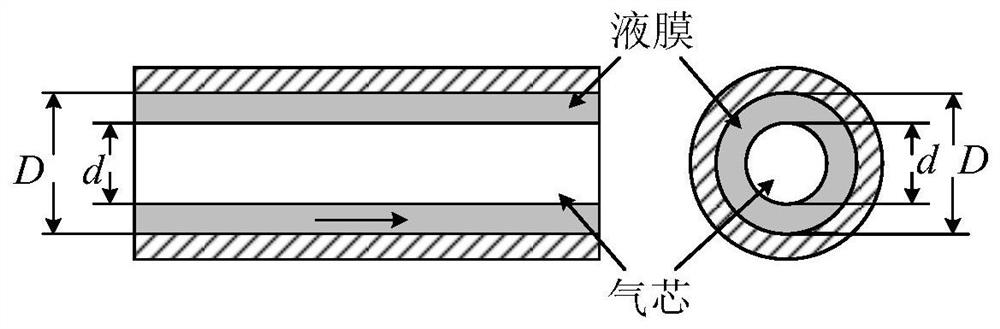

[0072] In the first step, the gas-liquid two-phase fluid in the swirling state enters the measuring tube 9, and the fixed cyclone 4 in the measuring tube 9 converts the gas-liquid two-phase fluid in the swirling state into two beams in the measuring tube 9. The single-phase fluid flowing in parallel in the tube 9, that is, the liquid phase flows against the inner wall of the measuring tube 9 to form a liquid film, and the gas phase flows in the center of the measuring tube 9 to form a gas core;

[0073] In the second step, tracer bubbles are planted in the liquid film at the accelerating nozzle 26 of the measuring tube 9, specifically as follows: open the gas mass flow controller 24 in the tracer bubble unit 20, and open the gas mass flow controller 24 in the central axis 28 of the cyclone 4. A small amount of gas enters the air-in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com