Electromagnetic friction counteracting transmission auxiliary device

An auxiliary device and electromagnetic technology, applied in the field of machinery, can solve the problems of insufficient transmission efficiency of small-power motors, shortening the service life of the motor, and limited load capacity of the motor, so as to improve the service life and transmission efficiency, enhance the moving speed, and reduce the motor load Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

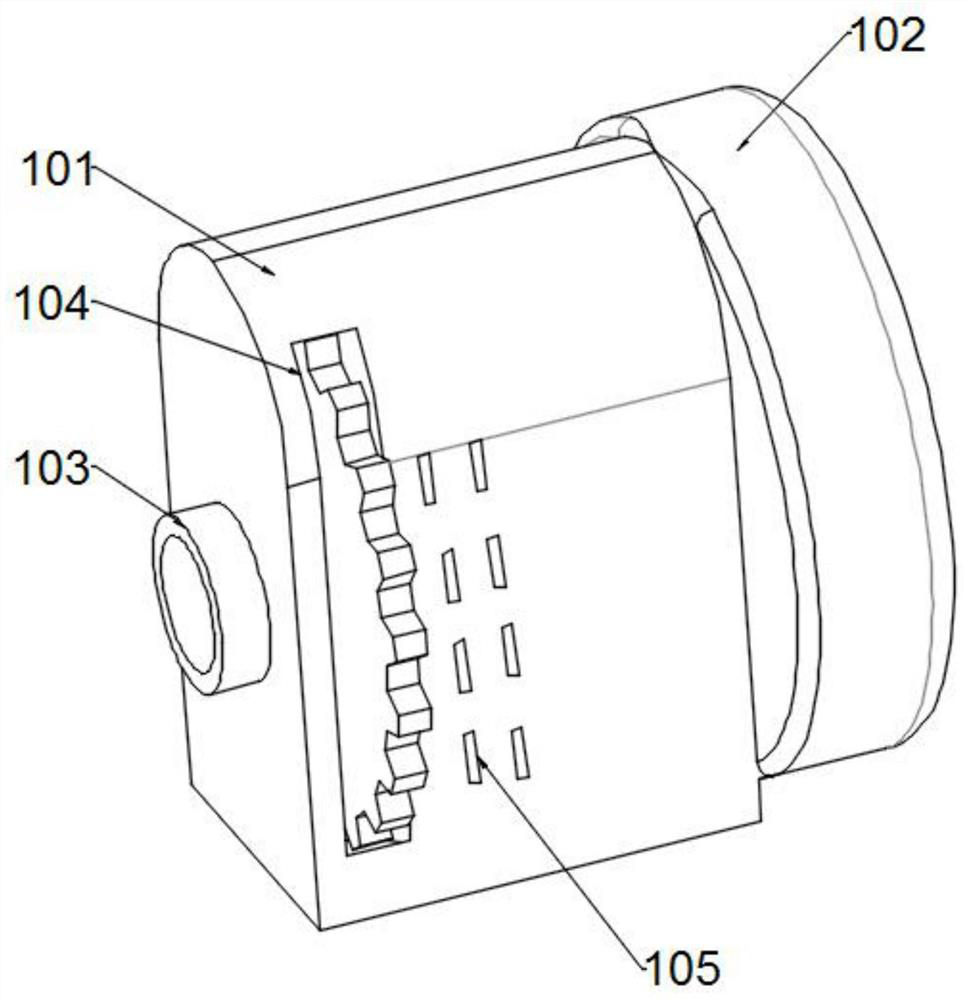

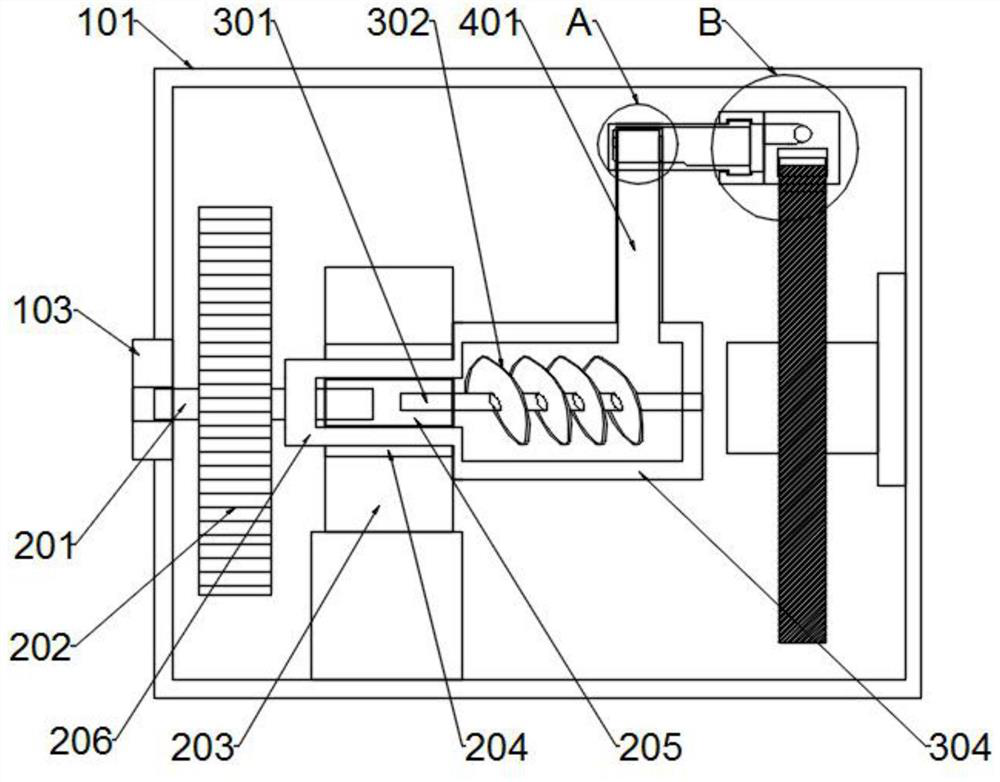

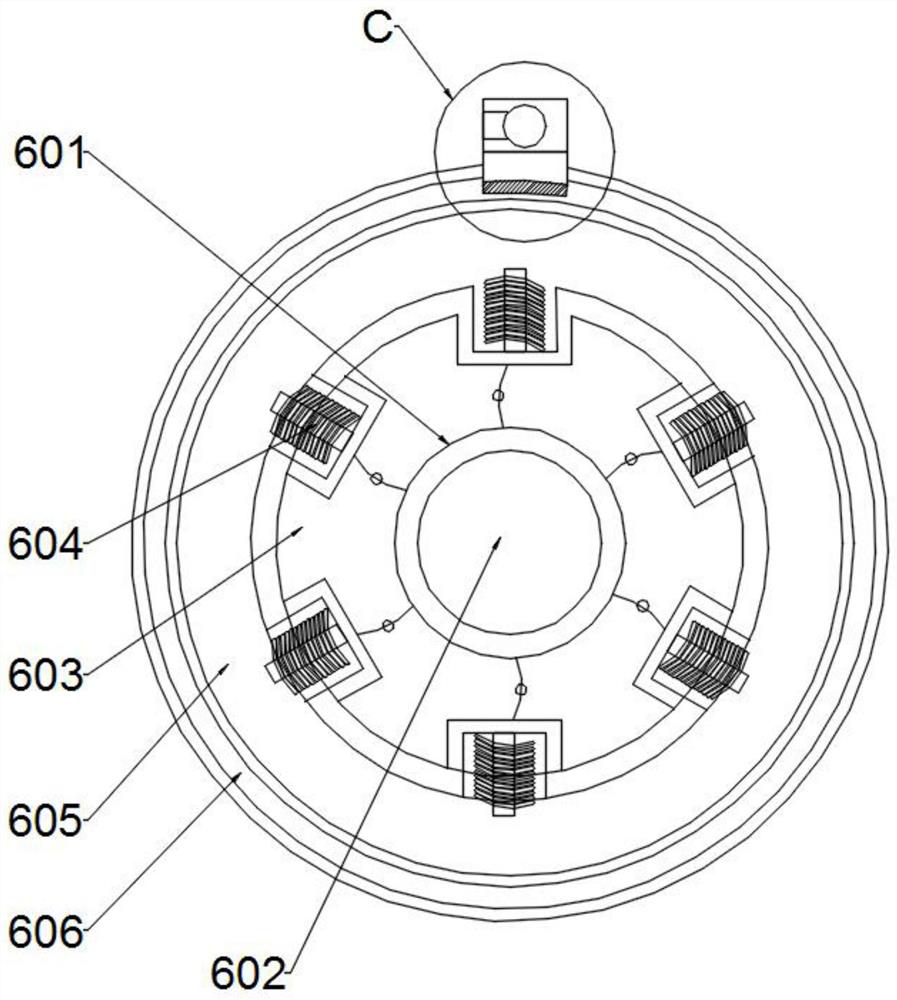

[0029] Example: such as Figure 1-7 As shown, an electromagnetic friction offset transmission auxiliary device includes a support assembly, a transmission assembly, a pneumatic assembly, an air flow assembly, a drive auxiliary assembly, and an electromagnetic centrifugal offset assembly. The support assembly is located at the outermost side of the entire device to support and protect the interior of the device. The role of the parts, the transmission component is installed at one end of the support component, and the transmission component plays the role of providing power for the external machine. Components, the airflow component plays the role of transmitting air flow, the side of the airflow component away from the pneumatic component is provided with a driving auxiliary component, the driving auxiliary component plays an auxiliary role in strengthening the transmission effect of the device, and the end of the supporting component far away from the transmission component is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com