Rapid egg tart skin extrusion forming device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

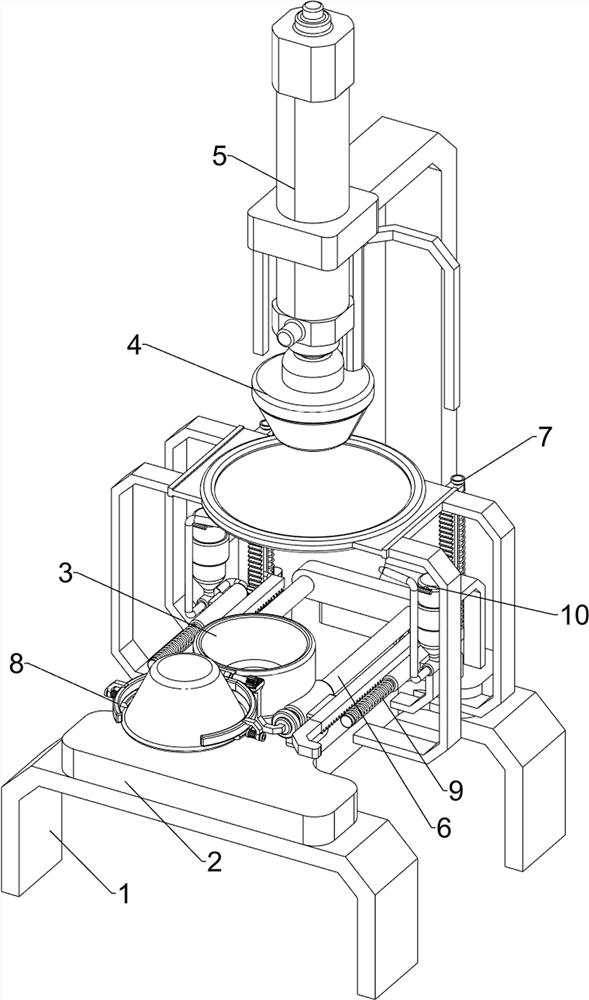

[0025] A quick extrusion molding device for egg tart skin, such as figure 1 and figure 2 As shown, it includes a support base 1, a workbench 2, an outer mold 3, an inner mold 4, an extrusion mechanism 5 and a placement mechanism 6, and the top of the support base 1 is provided with a workbench 2, and the workbench 2 is provided with a placement mechanism 6. The placement mechanism 6 is provided with an outer mold 3, the workbench 2 is provided with an extruding mechanism 5, and the extruding mechanism 5 is provided with an inner mold 4, and the inner mold 4 and the outer mold 3 cooperate with each other.

[0026] First, people place the egg tart skin in the outer mold 3, start the extrusion mechanism 5 to drive the inner mold 4 to move downward, and simultaneously push the outer mold 3 on the placement mechanism 6 backward, so that the inner mold 4 contacts the outer mold 3, and the outer mold The egg tart skin in 3 is extruded and finalized. After the egg tart skin is extru...

Embodiment 2

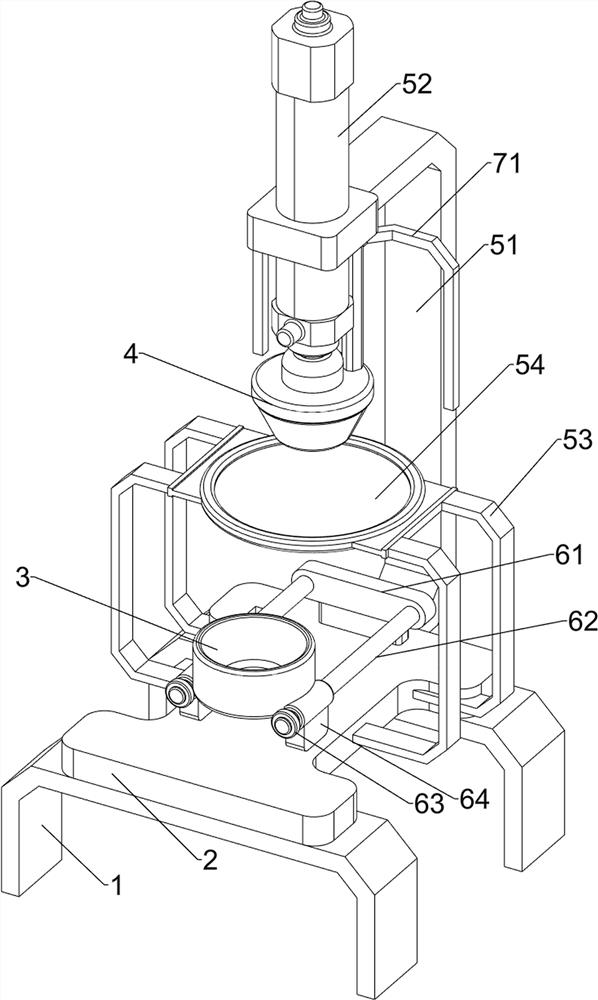

[0031] On the basis of Example 1, such as Figure 3-Figure 6 Shown, also includes push mechanism 7, and push mechanism 7 includes first push rod 71, second guide rod 72, first spring 73, first rack 74, mount 75, first gear 76 and second tooth Bar 77, the first push rod 71 is arranged symmetrically on the rear side of the top of the inner mold 4, and the second guide rod 72 is arranged symmetrically on the rear side of the workbench 2, and the first rack 74 is slidingly arranged on the second guide rod 72. The first spring 73 is connected between the first rack 74 and the workbench 2, and the first springs 73 are respectively set on the first guide rod 62. Two pairs of mounting seats 75 are symmetrically arranged on the rear side of the top of the workbench 2. Mounting seat 75 is equipped with a first gear 76 for rotation, and meshes between the first gear 76 and the first rack 74. The outside of the reinforcing block 64 is provided with a second rack 77, and the second rack 77...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap