Automatic lathe for nicking tool accessory machining

A technology for automatic lathes and accessories, which is applied to the accessories of tool holders, metal processing equipment, manufacturing tools, etc. It can solve the problems of no locking cap, single processing, etc., and achieve the effect of reducing cost and simple processing logic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] refer to Figure 1 to Figure 10 Embodiments of the present invention will be further described.

[0048] The invention is used for processing the cap with hollow structure. Its specific structure is:

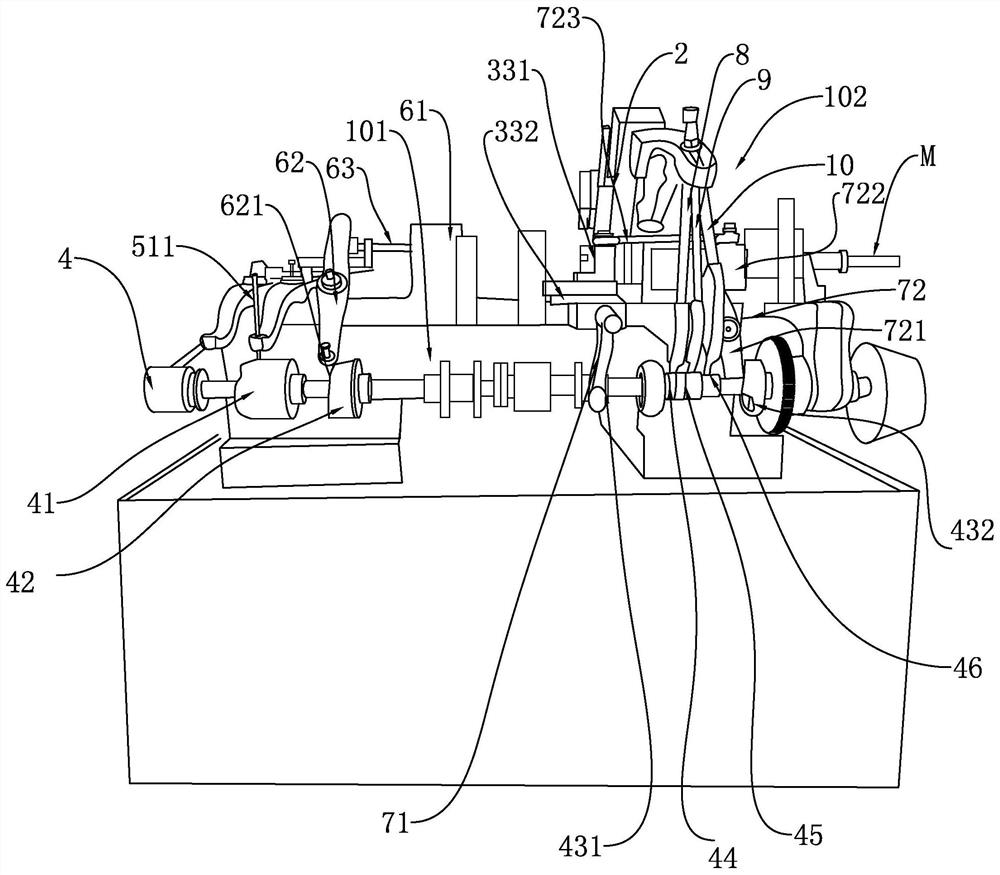

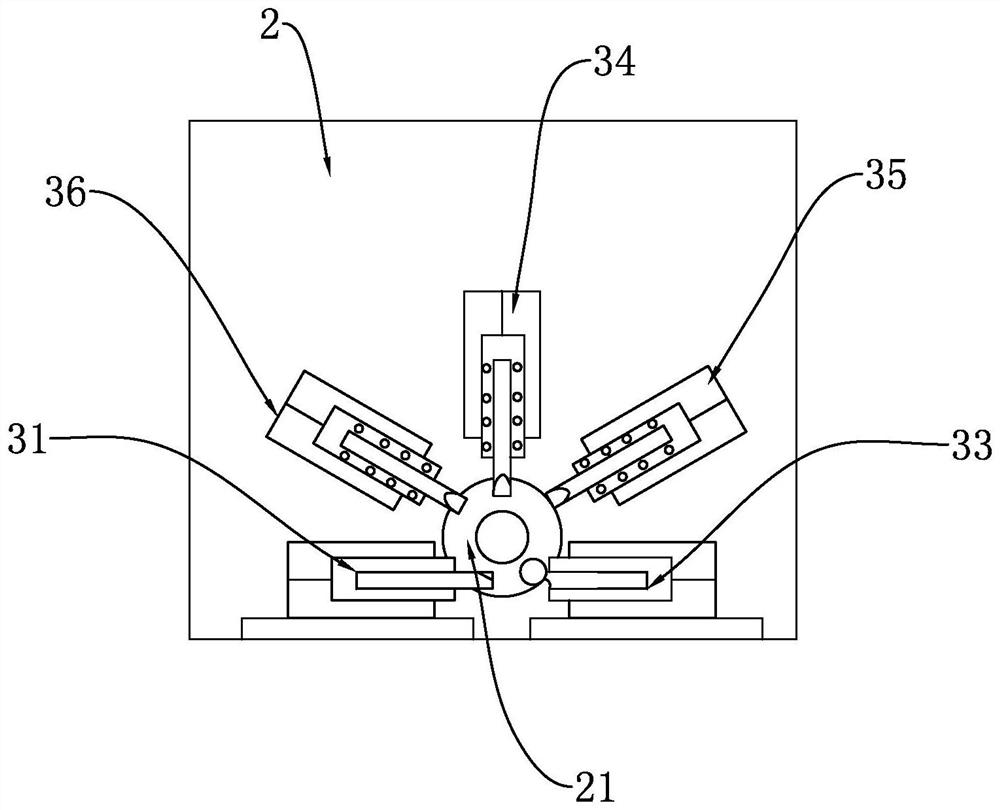

[0049] The lathe 1 has a workbench, a main machine 2 for providing power, and a forming device for processing caps.

[0050] The main machine 2 has a clamp 21 and a motor, the clamp 21 is rotatably connected to the main machine 2, and the clamp 21 is driven by the motor to control its rotation. The main machine 2 is connected front and back, and the clamp 21 is installed in front of the main machine 2. The hollow pipe W used for forming the cap can be inserted from the rear, and then clamped by the clamp 21. The main machine 2 also has a The cutter for cutting the section of the pipe W pulls the pipe W in front and ejects it when the pipe W behind is pushed forward.

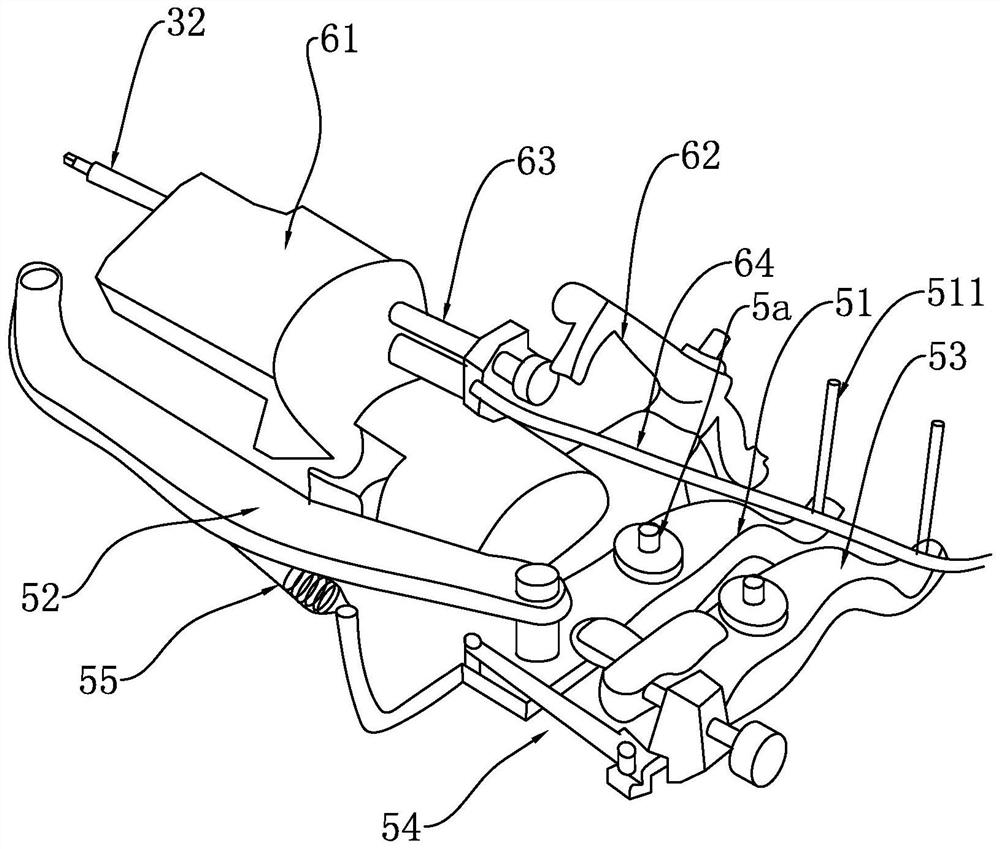

[0051] The forming device is placed on the workbench, and it includes a first cutter 31 for turning t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com