Piston boring and skirt bottom milling combined machine tool and process

A combination and piston technology, which is applied in the direction of manufacturing tools, metal processing equipment, metal processing machinery parts, etc., can solve the problems of low processing precision and low efficiency, achieve the effect of improving processing efficiency, avoiding a large amount of accumulation, and ensuring processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

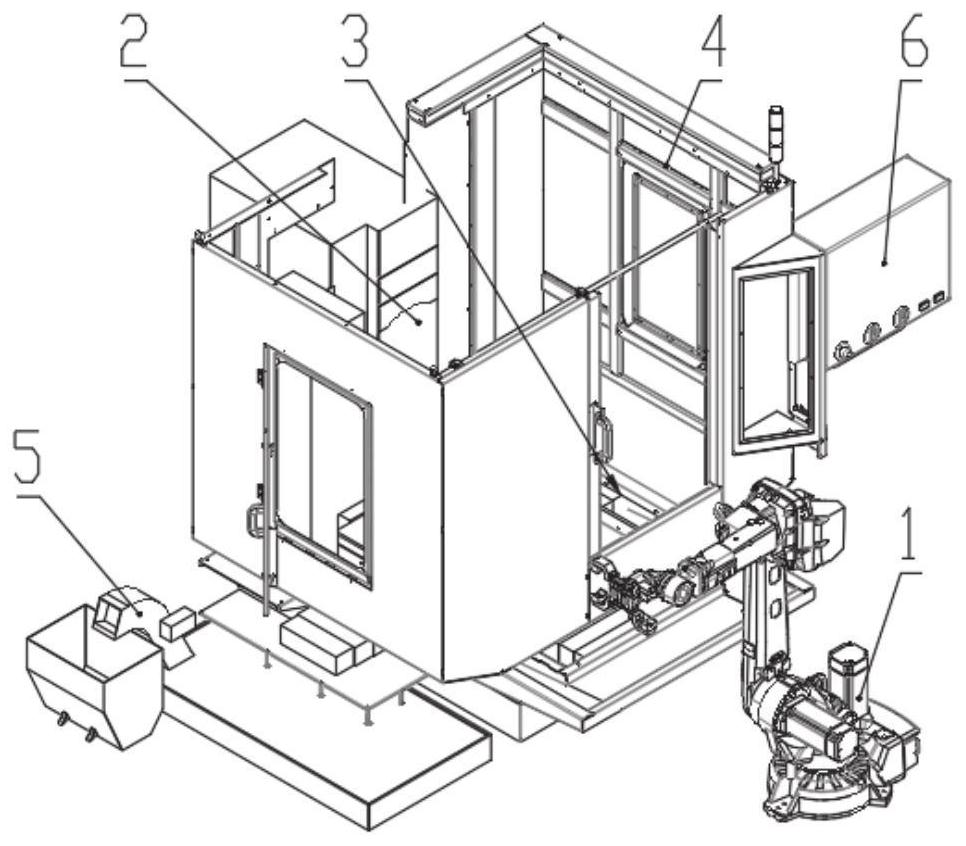

[0034] This embodiment provides a piston boring and milling skirt bottom combined machine tool, such as figure 1 As shown, including protective cover 4, piston positioning tool 3, milling mechanism 11, boring mechanism, manipulator 1, piston positioning tooling 3, milling mechanism 11 and boring mechanism are arranged in protective cover 4, and manipulator 1 is located in protective cover 4 outside.

[0035] Further, the protective cover 4 has a movable door, and by opening the movable door, the manipulator 1 realizes loading and unloading of the piston. The protective cover 4 of this embodiment is made of sheet metal, which can protect the machine tool and prevent personnel from being injured during machining. A numerical control operation unit 6 is installed on the outer side of the protective cover 4, and the numerical control operation unit 6 is composed of a display screen and operation buttons, which can realize man-machine dialogue.

[0036] The manipulator 1 includes...

Embodiment 2

[0048] This embodiment provides a process for machining pistons with a piston boring and milling skirt bottom combined machine tool, including:

[0049]When the piston is clamped, the moving door is in the open state, and the manipulator 1 places the piston to be processed on the piston positioning tool 3. After the piston is clamped and positioned, the manipulator 1 is released and the moving door is closed.

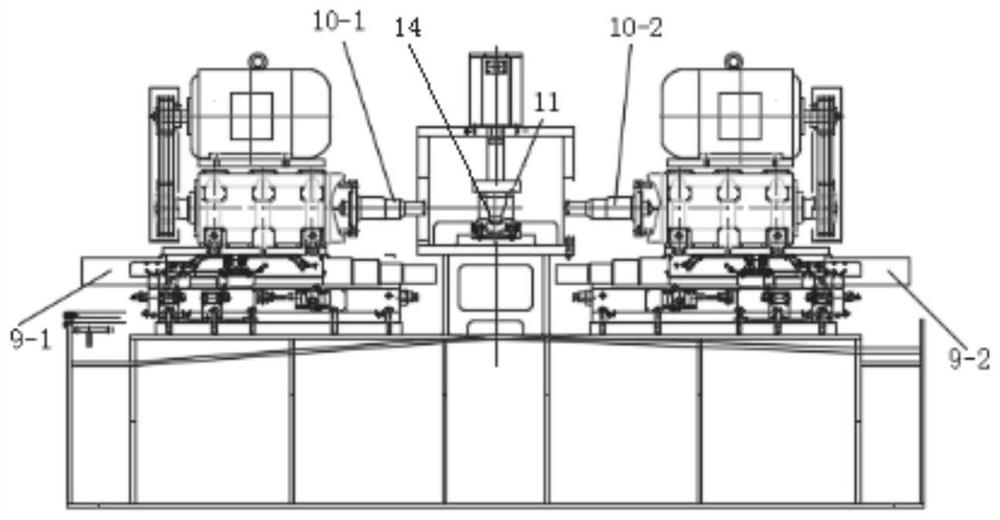

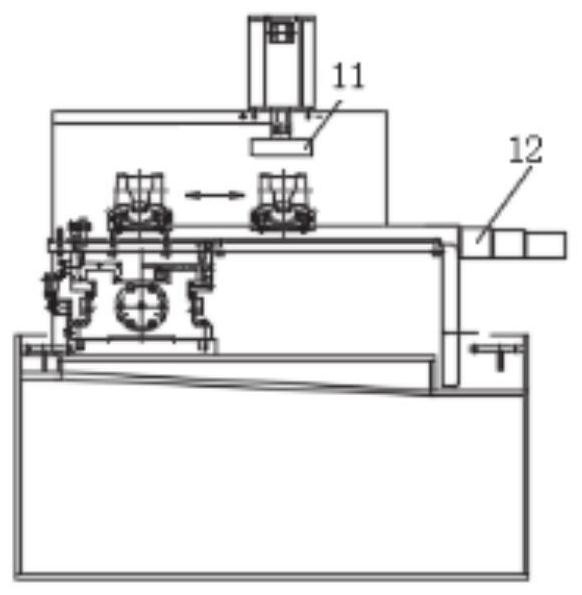

[0050] The position of the piston positioning tool 3 with the piston 14 clamped is adjusted through the Y-axis moving mechanism 12, and the two boring mechanisms are radially aligned with the piston 14.

[0051] The boring mechanism is moved along the X axis by the worktable moving mechanism, the two boring mechanisms are started, and the pin holes on both sides of the piston 14 are processed at the same time; after the boring is completed, the worktable moving mechanism moves in the opposite direction to make the boring mechanism withdraw from the pin hole.

[0052] St...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com