Intelligent tempered glass processing and fixing device based on functional glass

A fixing device and tempered glass technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problem of difficulty in fixing glass, and achieve the effects of stable and firm fixing, minimal friction, and convenient processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

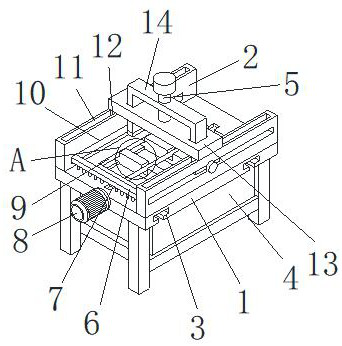

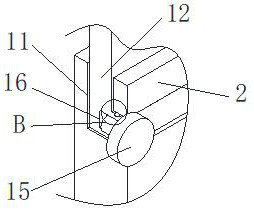

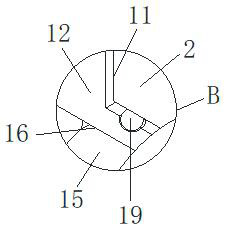

[0030] see Figure 1-3 , the present invention provides a technical solution: an intelligent processing and fixing device for tempered glass based on functional glass, including a workbench 1, two mirrored support blocks 2 are fixedly connected to the top of the workbench 1, and the two support blocks 2 are provided with There is the same structure, the inside of the support block 2 is provided with a second slide groove 11 with an L-shaped cross section, and the inside of the second slide groove 11 is slidably connected with a slide block 12, which is also L-shaped, and the top of the slide block 12 Equipped with glass fixtures;

[0031] The glass fixing device includes a support plate 13, the bottom of the support plate 13 is fixedly connected with the top of the slider 12, the inside of the support plate 13 is slidably connected with a fixed frame 14, the fixed frame 14 is U-shaped, and the bottom of the fixed frame 14 slides through the support plate 13 and extends to the o...

Embodiment 2

[0037] see Figure 1-5 , on the basis of Embodiment 1, the adjacent sides of the two supporting blocks 2 are all provided with a first sliding groove 10, and the inside of the first sliding groove 10 is slidingly connected with a cleaning frame 6, the cleaning frame 6 is T-shaped, and the cleaning frame 6 The bottom of the longitudinal bar is provided with a hairbrush, and the top of the workbench 1 is provided with a moving groove 7 slidingly connected to the surface of the vertical bar of the cleaning frame 6;

[0038] Further, the positive and negative motor 8 is fixedly connected to the left side of the workbench 1, and the positive and negative motor 8 is an existing structure. In the inside of the moving groove 7, the output end of the positive and negative motor 8 is fixedly connected with the second threaded rod 18 which is rotatably connected with the moving groove 7 inwall, and the surface of the second threaded rod 18 is threaded inside the cleaning frame 6 vertical...

Embodiment 3

[0043] see Figure 6 , on the basis of Embodiment 1 and Embodiment 2, the bottom of the workbench 1 is provided with a T-shaped card slot 3 in cross-section, and the inside of the card slot 3 is slidably connected with a card block 17, which is also T-shaped. The bottom of block 17 is fixedly connected with collection box 4;

[0044] Both the slot 3 and the block 17 are T-shaped, so that the position of the collection box 4 is limited, and the waste residue on the top of the workbench 1 is swept into the inside of the first chute 9 through the cleaning frame 6, and the waste residue enters the collection box 4 so that the staff can collect the waste slag more smoothly, and to a certain extent, prevent the waste slag from splashing around to pollute the environment and cause physical injury to the staff, thus making the working environment of the staff safer .

[0045] working principle:

[0046] The tempered glass intelligent processing fixture based on functional glass, in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com