Raw material preparation method for preparing high-whiteness and high-purity aluminum hydroxide by using solid waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

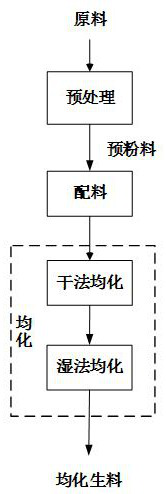

[0076] use as figure 1 A schematic flow chart of the raw meal preparation process for preparing high-white and high-purity aluminum hydroxide by using solid waste.

[0077] First, take fly ash, coal gangue, calcium carbide slag, coal powder, and soda ash, and carry out raw material pretreatment respectively, and use Raymond mill to grind the fineness to about 200 mesh to form pre-powder with the same material fineness. The mass percentages of fly ash, coal gangue, coal powder, calcium-containing solid waste and soda ash are: fly ash is 24%, coal gangue is 13%, calcium-containing solid waste is 42%, soda ash is 16%, coal The powder is 5%, and the raw meal is prepared. According to the 10-25% of the mass percentage of the dry homogenized raw meal, the water content is accurately measured and the batching is completed. In this embodiment, the pre-powder materials are sent to the intermediate silo of the raw materials respectively, and the batching is automated by the computer t...

Embodiment 2

[0084] The batching is carried out with reference to Example 1. The difference from Example 1 is that the fineness of the pre-powder is controlled at about 180 mesh.

[0085]First, take fly ash, coal gangue, coal powder, calcium carbide slag, and soda ash, and enter them into the Raymond mill for grinding to a fineness of about 180 mesh to form a pre-powder with the same material fineness, and then follow the measurement in Example 1 Batching Raw Meal Raw Meal Raw Meal Raw Meal Batching The water content is 10-25% of the mass percentage of the dry homogenized raw meal, accurately measured, and the raw meal batching is completed by microcomputer automatic batching.

[0086] First perform dry homogenization in a high-speed dry homogenizer, and then add 50°C water to carry out wet homogenization in a wet homogenizer. Homogenization time is 1-3 minutes, dry homogenization temperature is 50°C, wet homogenization control stirring speed is 200-500 rpm, wet homogenization temperature ...

Embodiment 3

[0089] The batching is carried out with reference to Example 1. The difference from Example 1 is that the fineness of the pre-powder is controlled at about 160 mesh.

[0090] First, take fly ash, coal gangue, coal powder, calcium carbide slag, and soda ash, and enter them into the Raymond mill for grinding to a fineness of about 160 mesh to form a pre-powder with the same material fineness, and then follow the measurement in Example 1 Batching Raw Meal Raw Meal Raw Meal Raw Meal Batching The water content is 10-25% of the mass percentage of the dry homogenized raw meal, accurately measured, and the raw meal batching is completed by microcomputer automatic batching.

[0091] First perform dry homogenization in a high-speed dry homogenizer, and then add 50°C water to carry out wet homogenization in a wet homogenizer. Homogenization time is 1-3 minutes, dry homogenization temperature is 50°C, wet homogenization control stirring speed is 200-500 rpm, wet homogenization temperature...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap