Method for synthesizing pH regulator by using fly ash

A technology of fly ash and conditioner, applied in the field of wastewater treatment, can solve the problems of low safety and high cost of bulk materials, and achieve the effect of high safety and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

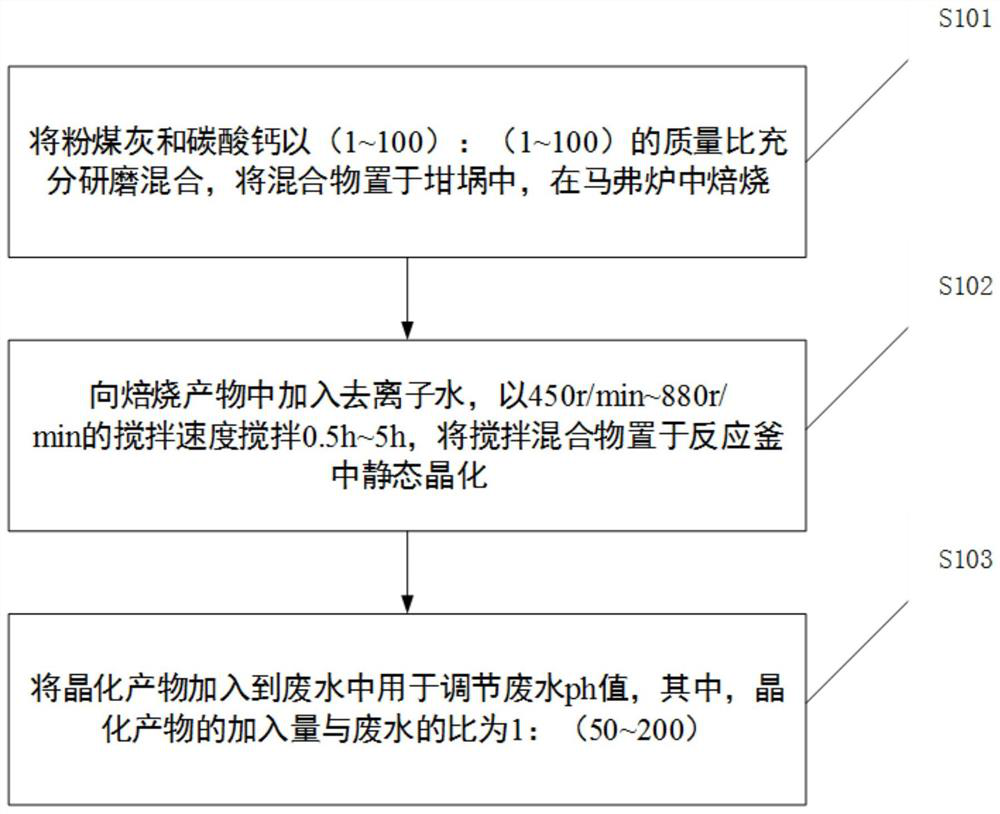

Method used

Image

Examples

Embodiment 1

[0028] According to the mass ratio CaCO3: fly ash = 1:10, put 1g CaCO3 and 10g fly ash into an agate mortar for grinding and mixing, put them into a crucible for roasting, cool down to room temperature, grind again, and add to the roasted product Stir with high-purity water, put it into a reaction kettle for aging, crystallize at 180°C, cool down to room temperature, and add both solid and liquid crystallization products into the wastewater at the same time. The initial pH of the wastewater was 3.3, the pH value was 9.8 after adding the synthetic pH regulator, and the pH value was 7.6 after standing for 3 days. At this point, filter the waste water with filter paper to separate the synthesized ph value adjuster solids.

Embodiment 2

[0030] According to the mass ratio CaCO3: fly ash = 3:7, put 3g CaCO3 and 7g fly ash into an agate mortar, grind and mix them, put them into a crucible and roast them, cool down to room temperature, grind again, and add to the roasted product Stir with high-purity water, put it into a reaction kettle for aging, crystallize at 180°C, cool down to room temperature, and add both solid and liquid crystallization products into the wastewater at the same time. The initial pH of the wastewater was 3.4, the pH value was 10.3 after adding the synthetic pH regulator, and the pH value was 7.8 after 3 days of storage. At this point, filter the waste water with filter paper to separate the synthesized ph value adjuster solids.

Embodiment 3

[0032] According to the mass ratio CaCO3: fly ash = 3:7, put 3g CaCO3 and 7g fly ash into an agate mortar, grind and mix them, put them into a crucible and roast them, cool down to room temperature, grind again, and add to the roasted product Stir with high-purity water, put it into a reaction kettle for aging, crystallize at 180°C, cool down to room temperature, and add both solid and liquid crystallization products into the wastewater at the same time. The initial pH of the waste water was 9.8, the pH value was 10.8 after adding the synthetic pH regulator, and the pH value was 8.1 after 3 days of storage. At this point, filter the waste water with filter paper to separate the synthesized ph value adjuster solids.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com