Environment-friendly fluff removing machine for spinning

A velvet machine, environmental protection technology, applied in the field of environmental protection velvet machine for textiles, to achieve the effect of simple switching mode, convenient cleaning, and high practical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The preferred examples of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred examples described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

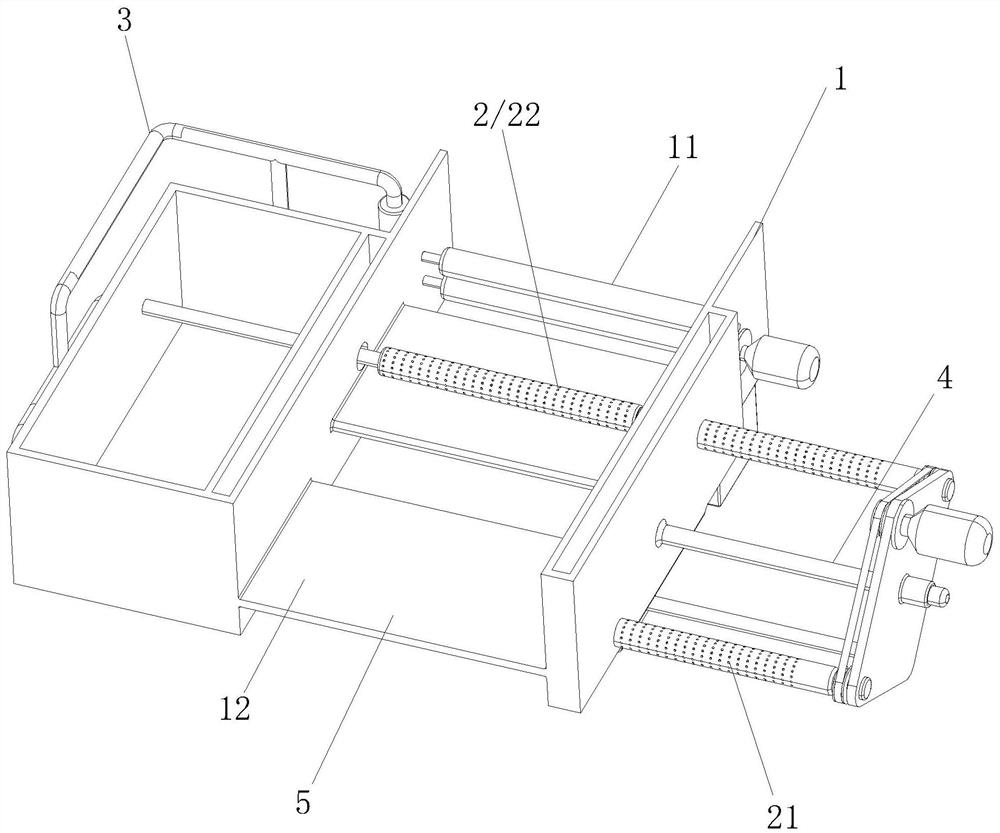

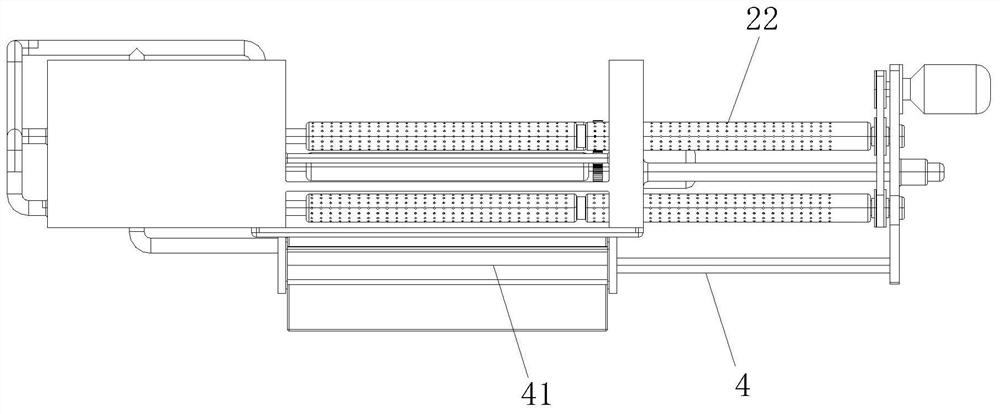

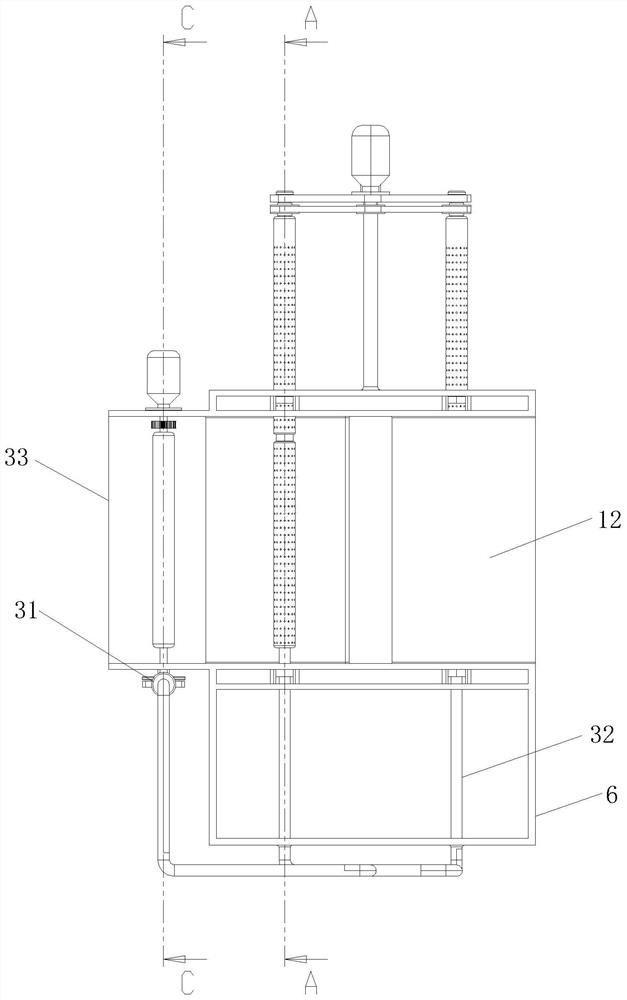

[0023] Such as Figures 1 to 6 As shown, this environmentally friendly delinting machine for textiles includes a frame 1 on which an adsorption mechanism 2 , a vacuum pipeline mechanism 3 , a switching mechanism 4 and an adsorption station 5 are arranged. Wherein, the adsorption mechanism 2 includes two adsorption groups 21, and each adsorption group 21 includes two adsorption rollers 22 that are hollow inside and hollowed out on the surface. The two adsorption rollers 22 between two adjacent groups of adsorption groups 21 are in one-to-one correspondence, and the corresponding two adsorption rollers 22 are coaxially fixedly connected. In addition, the two adsorption rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com