Equipment and method for recovering volatile organic compounds

A volatile organic compound and equipment technology, applied in the field of volatile organic compound recovery equipment, can solve the problems of low saturation rate of spherical activated carbon, increase recovery cost, and inability to adsorb toluene, achieve high-efficiency adsorption, reduce recovery cost, and ensure adsorption efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

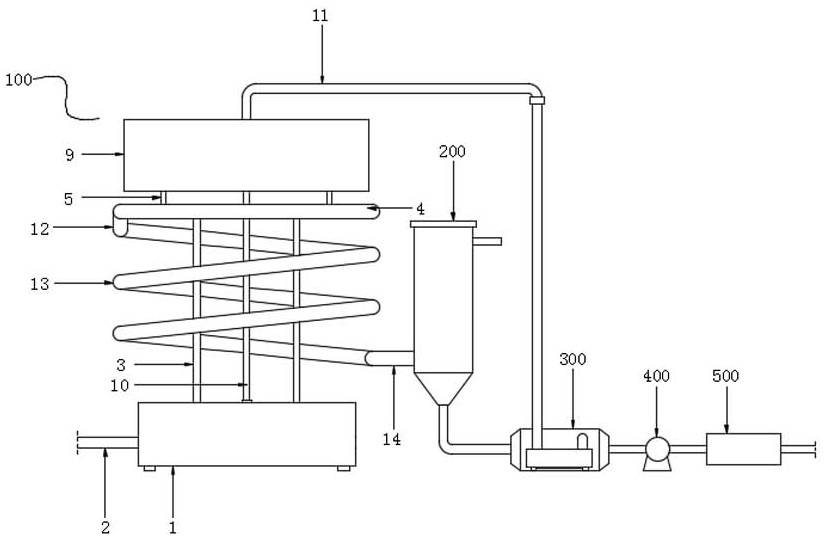

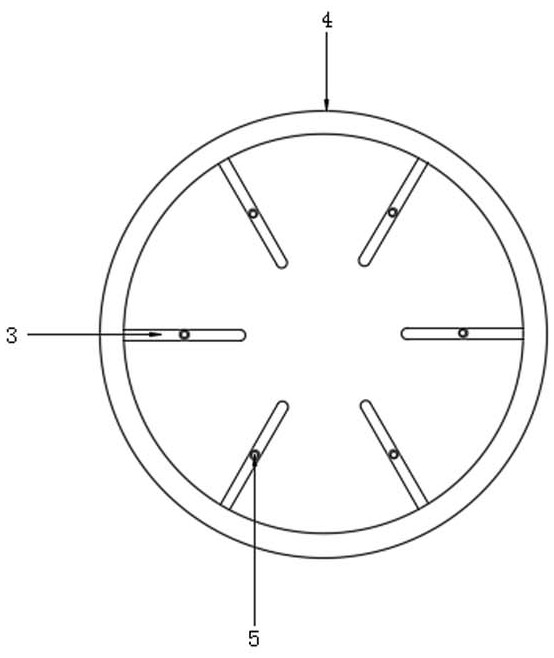

[0034] The present invention provides such as Figure 1-5 A device for recovering volatile organic compounds is shown, comprising an adsorption assembly 100, a cyclone separator 200, a desorber 300, an induced draft fan 400 and a condenser 500, the adsorption assembly 100, a cyclone separator 200, a desorber 300, an induction The fan 400 and the condenser 500 are communicated in sequence, and the desorber 300 is communicated with the adsorption assembly 100 through the adsorbent return mechanism 11 in the adsorption assembly 100. The adsorption assembly 100 includes a first sealed box 1, an L-shaped shunt pipe 3, and an annular junction Pipe 4, adsorbent feeding pipe 5, hopper 6 and a plurality of spherical activated carbon 7.

[0035] More specifically, the left side of the first sealed box 1 is fixedly provided with an exhaust gas input pipe 2, and a plurality of L-shaped shunt pipes 3, adsorbent feeding pipe 5 and hopper 6 are provided, and a plurality of L-shaped shunt pip...

Embodiment 2

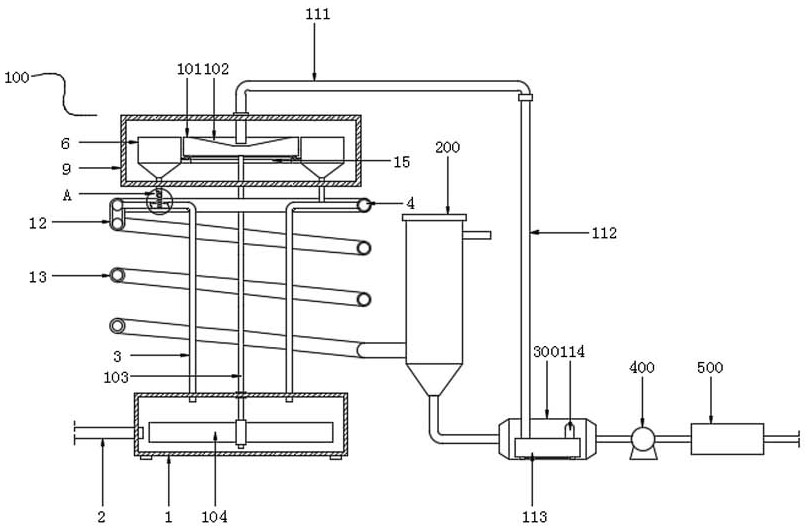

[0047] The difference from the above-mentioned embodiment is that, if Figure 6 and Figure 7 As shown, since the plurality of spherical activated carbons 7 inside the hopper 6 are prone to jamming during the feeding process, in order to avoid the above problems:

[0048] Two-way vibrating mechanism 15 is arranged between the bottom of bulk material pan 101 and multiple hoppers 6 insides, and bidirectional vibrating mechanism 15 comprises upper vibrating ring 151, lower vibrating ring 152, a plurality of semicircular cylinders 153 and a plurality of hemispherical extruders. The pressing block 154, the upper vibrating ring 151 are fixedly arranged on the inner bottom of multiple hoppers 6, the lower vibrating ring 152 is fixedly arranged on the bottom of the bulk material tray 101, and the lower vibrating ring 152 is located directly above the upper vibrating ring 151, and the plurality of semicircular columns The body 153 is evenly and fixedly arranged on the top of the upper...

Embodiment 3

[0051] The difference from the above-mentioned embodiment is that, if figure 2 and Figure 5 As shown, after the recovered spherical activated carbon 7 falls into the screw feeding pipe 112, in order to make the spherical activated carbon 7 enter into a plurality of hoppers 6 from the screw feeding pipe 112 more conveniently, avoid the The situation that the spherical activated carbon 7 in a certain hopper 6 is used up, and the air flow inside the L-shaped shunt pipe 3 connected to the adsorbent feeding pipe 5 at the bottom runs empty:

[0052] In the present invention, a plurality of hoppers 6 are distributed in a ring shape, and the rotating impeller 104 is used to drive the bulk material disc 101 to rotate synchronously through the drive rod 103, so that the spherical activated carbon 7 falling into the conical groove 102 is driven by the bulk material disc. The centrifugal force generated when 101 rotates is evenly thrown into multiple hoppers 6, thereby avoiding the occ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com