Method and device for cooperative treatment of waste gas and wastewater from automobile repair factories

A technology for collaborative processing and auto repair plants, which is applied in the direction of gaseous effluent wastewater treatment, gas treatment, water/sewage treatment, etc., and can solve the problems of increased energy consumption, total emissions of air pollutants exceeding the environmental capacity, and unstable business sites, etc. problems, to achieve the effect of increasing the three-phase mass transfer rate, reducing the occupied area, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

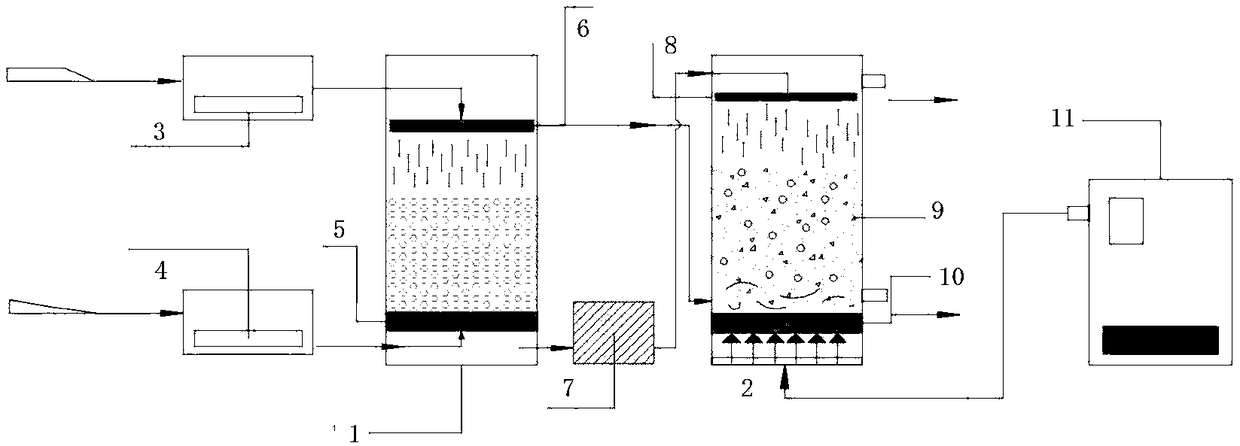

[0028] Example 1 Device for Cooperative Treatment of Exhaust Gas and Wastewater in Auto Repair Plant

[0029] like figure 1 As shown, the device for the co-processing of waste gas and wastewater in auto repair plants of the present invention includes a first absorption tower 1 , a grease trap 7 and a second absorption tower 2 connected in sequence. The top of the first absorption tower 1 is provided with a first spraying device 6, the top of the first absorption tower 1 is provided with a waste water inlet and a waste gas outlet, and the bottom part is provided with a waste gas inlet and a waste water outlet; the grease trap 7 includes a waste water inlet and a waste water outlet, and the waste water inlet is connected to the waste water outlet. The first absorption tower 1 is connected to the waste water outlet; the second absorption tower 2 is provided with a second spray device 8 on the top, the upper part of the second absorption tower 2 is provided with a waste water inle...

Embodiment 2

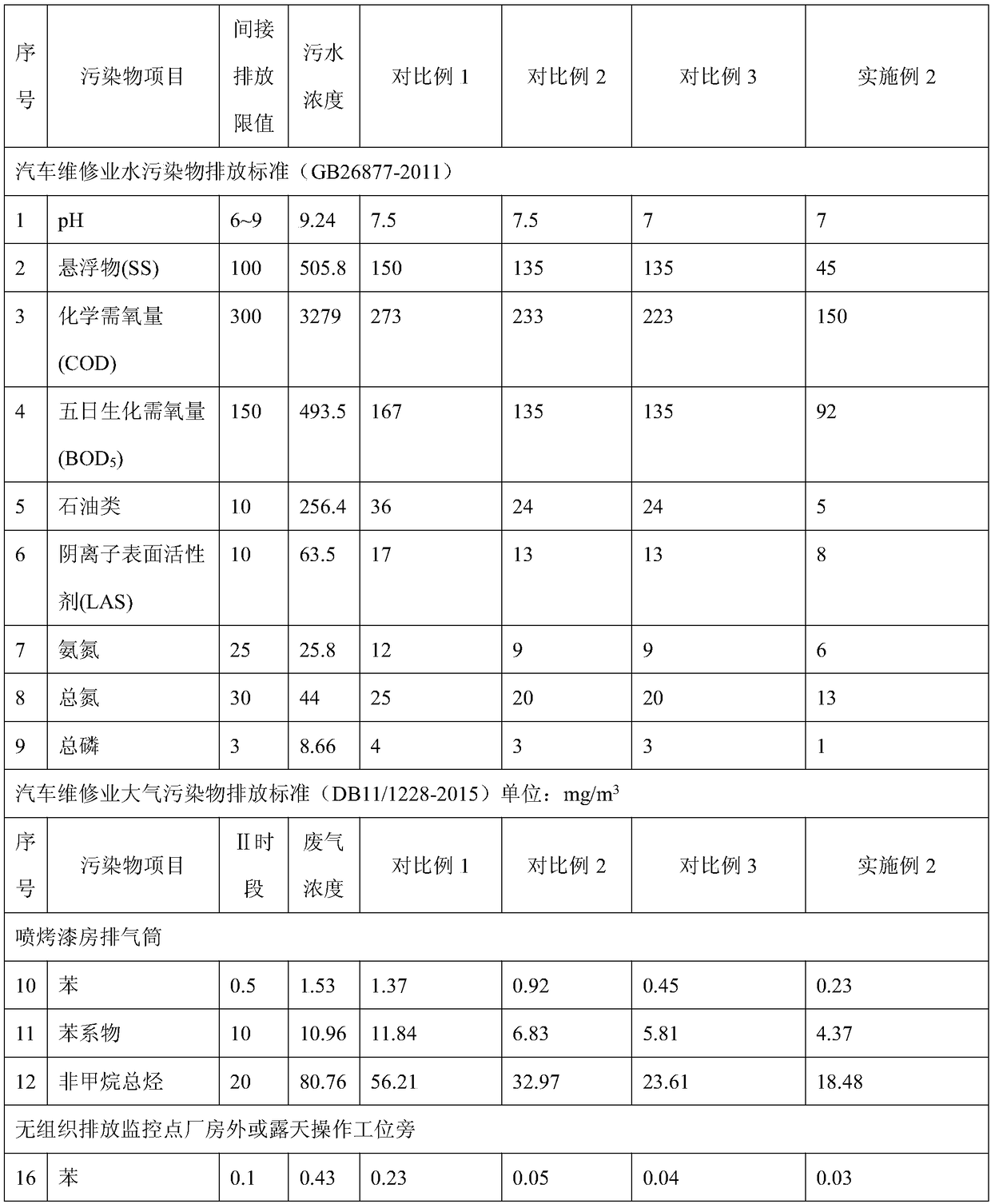

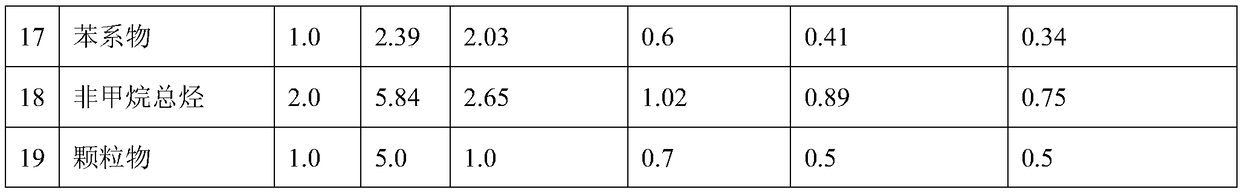

[0033] Embodiment 2 The method for the synergistic treatment of exhaust gas and wastewater in auto repair plants

[0034] Adopt the device of embodiment 1 to carry out synergistic treatment to waste gas waste water of auto repair factory, method is as follows:

[0035] like figure 1As shown, the alkali-containing waste water from the auto repair plant is buffered in the waste water regulating tank 3 and then pumped into the first absorption tower 1 through the waste water inlet on the upper part of the first absorption tower 1, and the waste gas from the auto repair plant is sent into the waste gas through the waste gas regulating device 4. The waste gas inlet at the lower part of the first absorption tower 1, the waste water enters the first absorption tower 1 and is evenly sprayed by the first spray device 6, scattered and falls, and the waste gas passes through the waste gas distributor 5 and contacts the waste water from the top of the tower in countercurrent, and the wast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com