Preparation method and application of self-cleaning gel with adsorption-photocatalysis synergistic effect

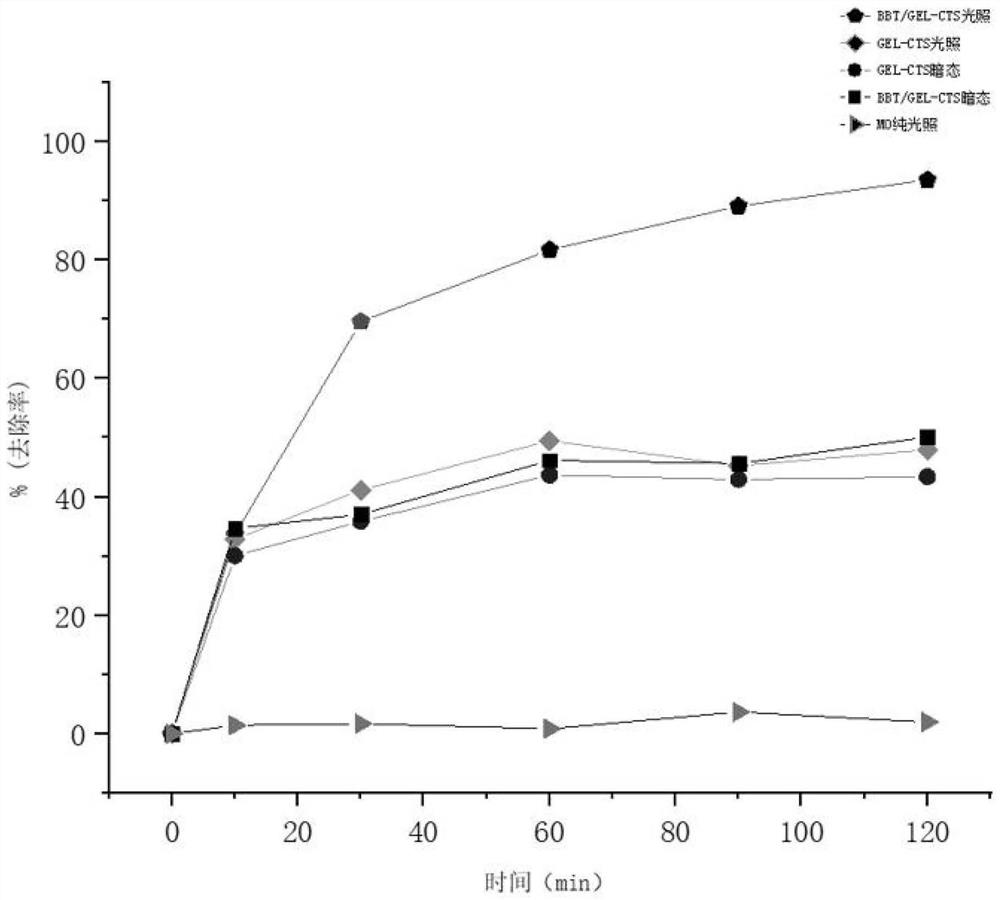

A synergistic, photocatalytic technology, used in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problem of not really eliminating pollutants, secondary pollution, consuming more energy and other resources, etc problem, to achieve the effect of significant adsorption-photocatalytic synergistic performance, efficient adsorption, and obvious self-cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

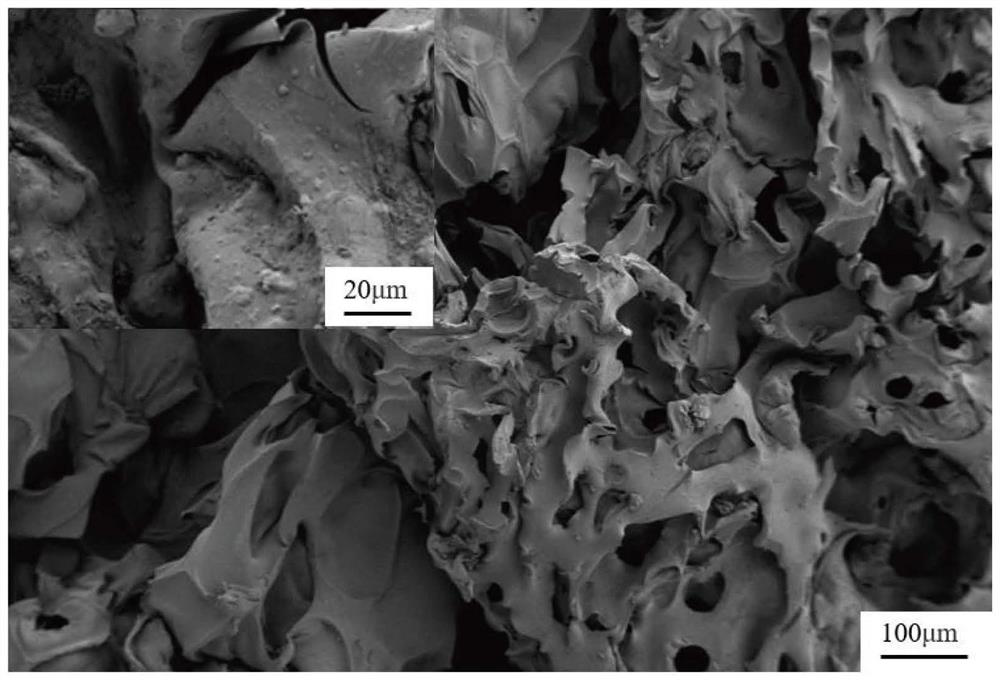

[0038] The preparation method of the self-cleaning gel with the synergistic effect of adsorption-photocatalysis in the present embodiment comprises the following steps:

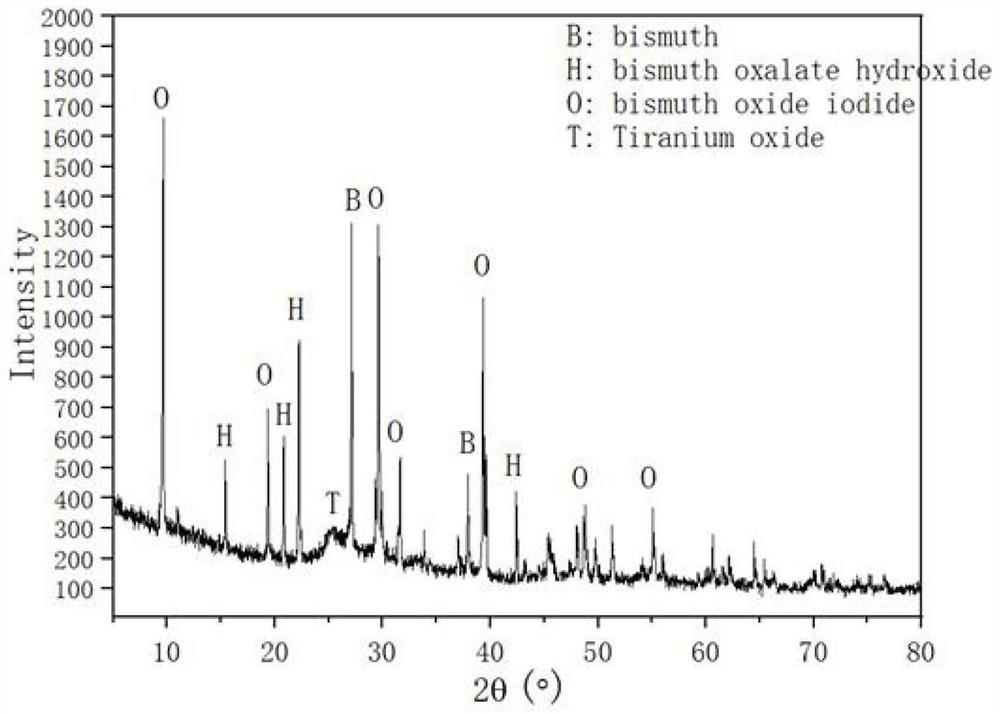

[0039] S1. Preparation of photocatalytic materials modified by bismuth titanium halogen:

[0040] Add 0.33 g of bismuth nitrate pentahydrate to 60 mL of absolute ethanol, ultrasonically until dissolved, to obtain solution A; mix 15 mL of tetrabutyl titanate and 15 mL of absolute ethanol, and magnetically stir for 30 min to obtain solution B; dissolve 0.78 g of iodic acid In 15 mL of deionized water a, an aqueous solution of iodic acid was obtained; the aqueous solution of iodic acid was kept in a state of magnetic stirring, the solution B was added dropwise, and then magnetic stirring was performed for 30 min to obtain a uniformly dispersed milky white suspension; The solution A and the milky white suspension were mixed and stirred for 60 min to obtain a precursor colloidal substance; the dropwise addition sp...

Embodiment 2

[0064] The preparation method of the self-cleaning gel with the synergistic effect of adsorption-photocatalysis in the present embodiment comprises the following steps:

[0065] S1. Preparation of photocatalytic materials modified by bismuth titanium halogen:

[0066] Add 0.44 g of bismuth nitrate pentahydrate to 80 mL of absolute ethanol, and sonicate until dissolved to obtain solution A; mix 30 mL of tetrabutyl titanate and 30 mL of absolute ethanol, and magnetically stir for 30 min to obtain solution B; dissolve 0.78 g of iodic acid In 15 mL of deionized water a, an aqueous solution of iodic acid was obtained; the aqueous solution of iodic acid was kept in a state of magnetic stirring, the solution B was added dropwise, and then magnetic stirring was performed for 30 min to obtain a uniformly dispersed milky white suspension; The solution A and the milky white suspension were mixed and stirred for 60 min to obtain a precursor colloidal substance; the dropwise addition rate ...

Embodiment 3

[0080] The preparation method of the self-cleaning gel with the synergistic effect of adsorption-photocatalysis in the present embodiment comprises the following steps:

[0081] S1. Preparation of photocatalytic materials modified by bismuth titanium halogen:

[0082] Add 0.33 g of bismuth nitrate pentahydrate to 60 mL of absolute ethanol, and ultrasonicate until dissolved to obtain solution A; mix 15 mL of tetrabutyl titanate and 15 mL of absolute ethanol, and stir magnetically for 30 min to obtain solution B; dissolve 0.78 g of iodic acid In 15 mL of deionized water a, an aqueous solution of iodic acid was obtained; the aqueous solution of iodic acid was kept in a state of magnetic stirring, the solution B was added dropwise, and then magnetic stirring was performed for 30 min to obtain a uniformly dispersed milky white suspension; The solution A and the milky white suspension were mixed and stirred for 60 min to obtain a precursor colloidal substance; the dropwise addition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com