A kind of construction method of concrete in the climbing corridor part of roller compacted concrete dam

A technology of roller compacted concrete and construction method, which is applied in sea area engineering, water conservancy engineering, infrastructure engineering, etc. It can solve the problems of long time for storage, complex construction process, slow construction progress, etc., and achieves easy promotion and use, hoisting means The effect of easy solution and fast warehouse preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

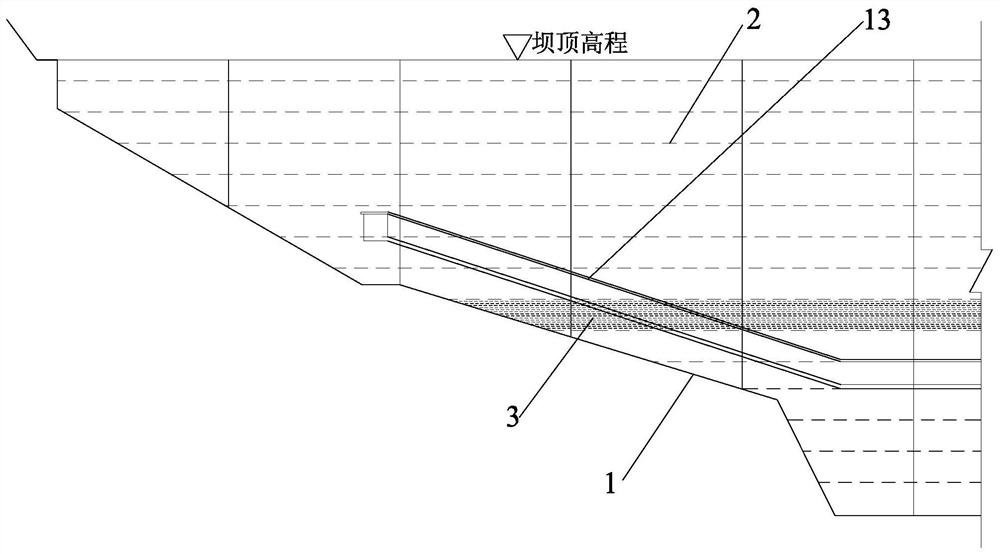

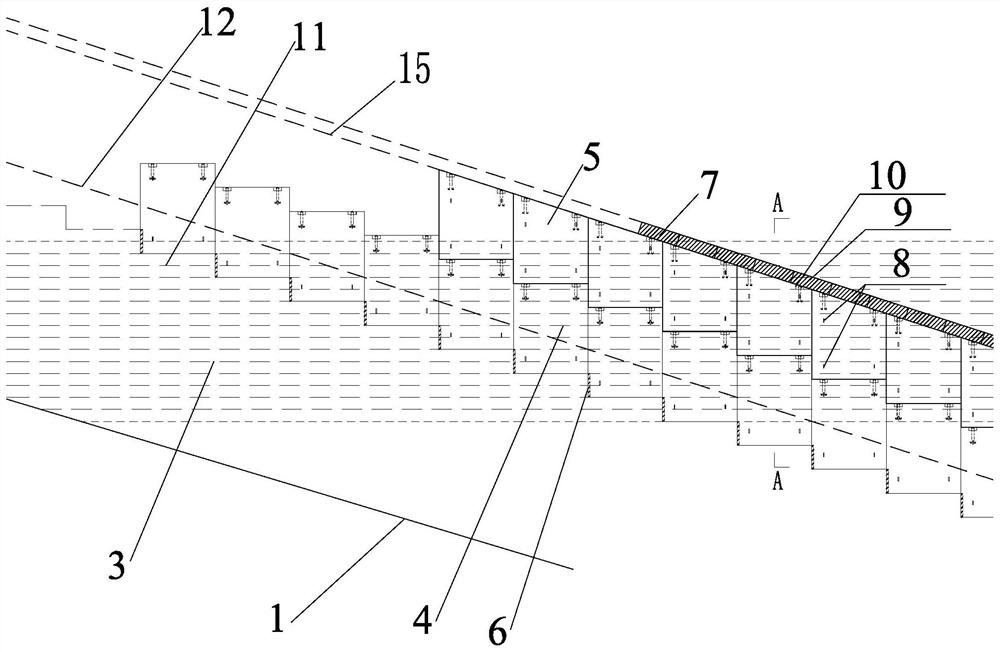

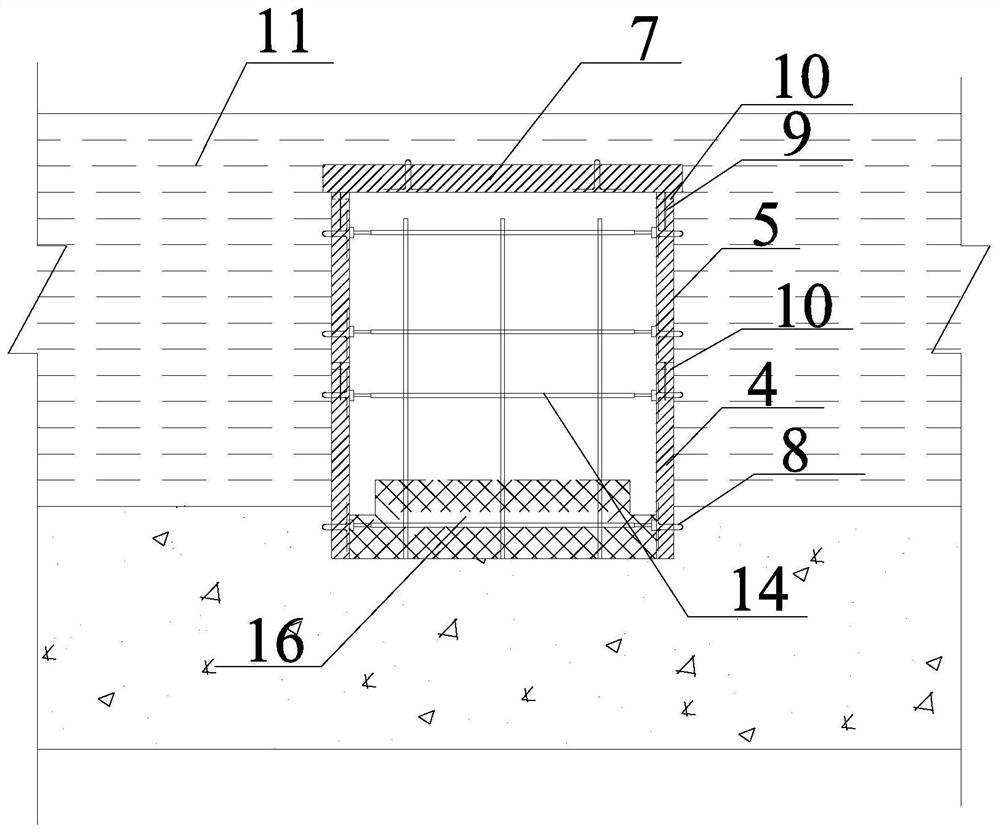

[0047] like Figure 1 to Figure 6 As shown in the figure, a construction method of the concrete at the part of the roller compacted concrete dam climbing corridor of the present invention comprises the following steps:

[0048] Step 1. Layering of the RCC dam: Use the dam RCC layered pouring line 2 to layer the 13 parts of the dam climbing corridor of the RCC dam, and obtain multiple dam roller compactions from bottom to top. Concrete layer to be poured;

[0049] Then use the roller compacted concrete germ layer line 11 to layer the roller compacted concrete to be poured layer of the dam, and obtain a plurality of roller compacted concrete germ layers to be poured from bottom to top;

[0050] Among them, the dam climbing corridor 13 is arranged in the climbing direction;

[0051] Step 2: Concrete layered pouring at the climbing corridor of the RCC dam: perform layered pouring of multiple dam RCC layers to be poured from bottom to top, and obtain each layer of dam RCC pouring l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com