Phased array curved surface full-focusing imaging optimization method and system for sound field threshold segmentation

A technology of threshold segmentation and optimization method, which is applied in the analysis of solids by using sound wave/ultrasonic wave/infrasonic wave, material analysis and material analysis by using sound wave/ultrasonic wave/infrasonic wave. Participate in calculations, improve algorithm efficiency and imaging signal-to-noise ratio, and ensure the effect of defect imaging quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

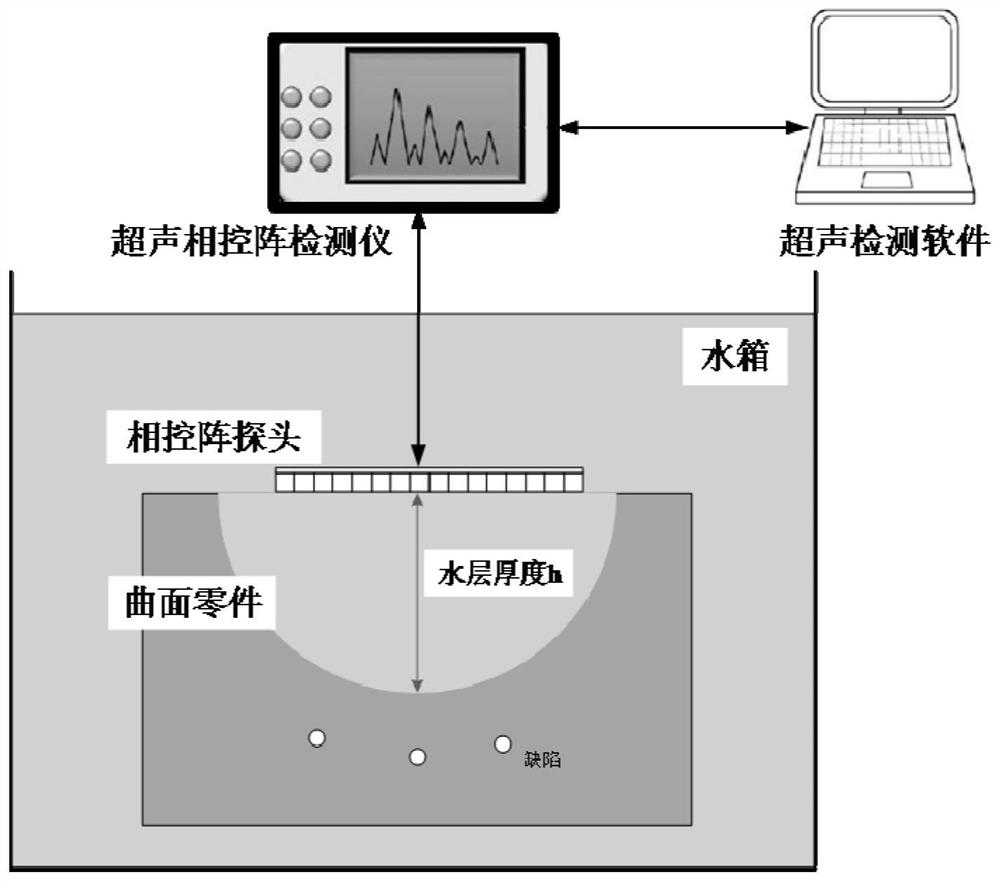

[0043] Such as figure 1 As shown, the water immersion all-focus detection system of the embodiment of the present invention includes a water tank, a curved surface part to be tested, a linear ultrasonic phased array probe, an ultrasonic phased array detector and a computer, wherein ultrasonic detection software is installed in the computer. The ultrasonic testing software mainly implements the phased array curved surface all-focus imaging optimization method of sound field threshold segmentation.

[0044] The phased array curved surface all-focus imaging optimization method for sound field threshold segmentation in the embodiment of the present invention mainly includes the following steps:

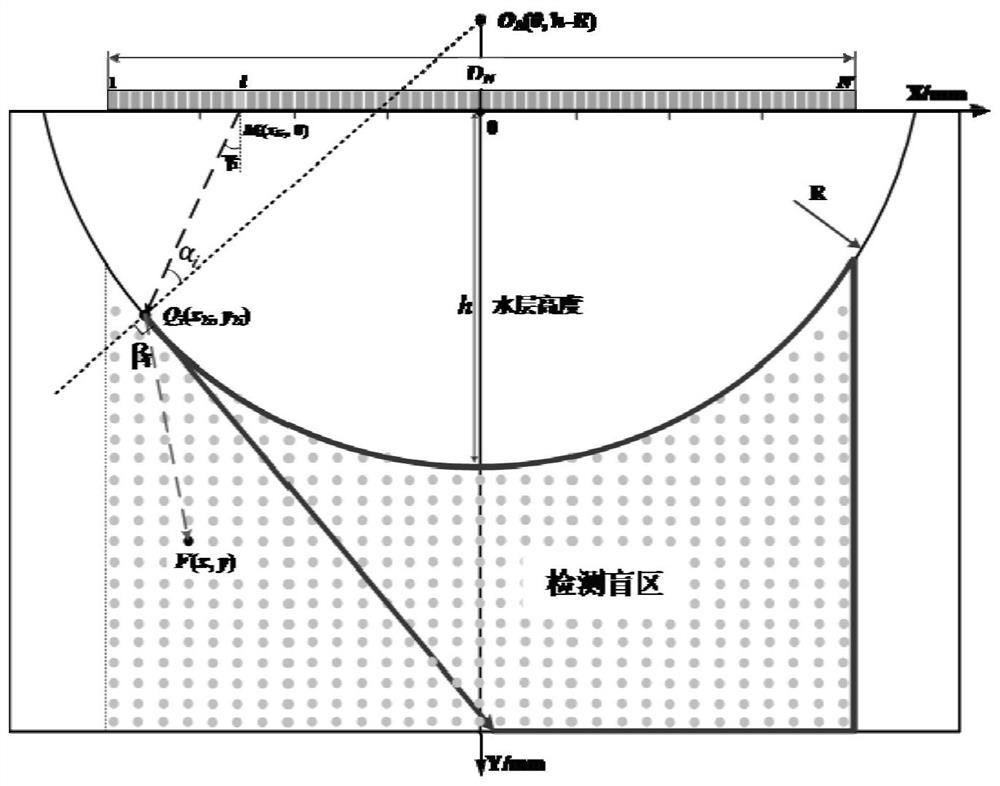

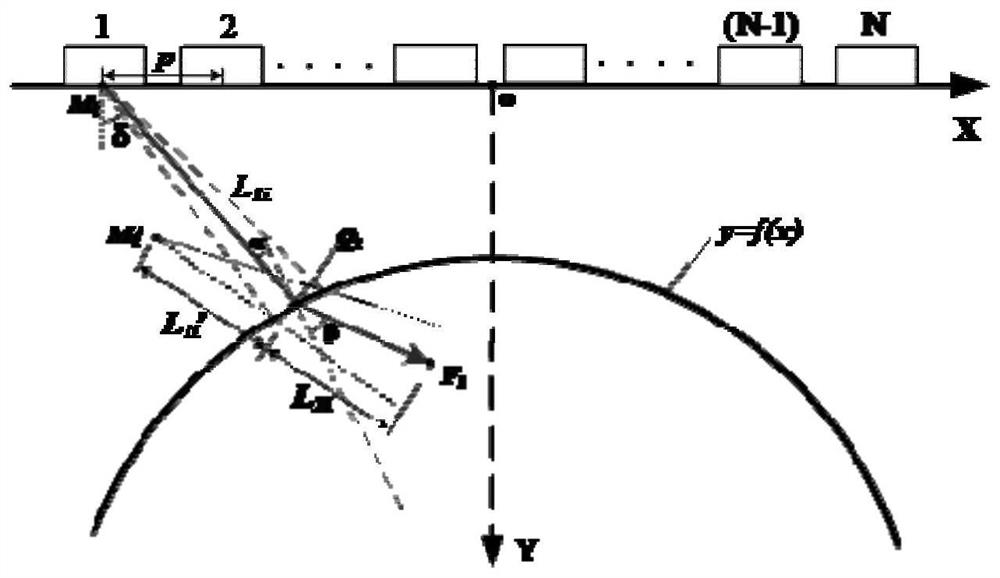

[0045] Step (1): Determine the detection parameters such as probe frequency f, number of array elements N, array element width d, array element spacing p, and water layer height h according to the material of the curved surface part to be tested and the curvature of the curved surface;

[...

Embodiment 2

[0087] Such as Figure 4 As shown, the goal of this embodiment is the detection of the curved surface area of the aero-engine air intake casing ring forging: the convex area R=15mm, and the transverse through hole defect with a diameter of 1.2mm is processed; the concave area R=20mm, respectively processed with a diameter of 0.5mm , 1.0mm and 1.5mm transverse through-hole defects, the material is titanium alloy TC2, the longitudinal wave sound velocity is 6163m / s, and the density is 4.55g / cm3 .

[0088] The ultrasonic all-focus detection and imaging optimization of the aero-engine casing ring forging in the embodiment of the present invention includes the following steps:

[0089] Step (1): The present invention adopts a linear phased array probe water immersion method to detect, the probe frequency is 10MHz, the number of probe array elements is N=64, the array element interval is p=0.3mm, and the distance between the center of the convex surface and the height of the probe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Snr | aaaaa | aaaaa |

| Snr | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com