Precise electromagnetic calibration method for orientation of ultra-deep underground pipeline

A calibration method and pipeline technology, which can be used in electromagnetic wave detection and other directions, and can solve the problem of inability to effectively obtain pipeline orientation information.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] Example 1: Ultra-deep underground pipeline burial position measuring instrument

[0051] The ultra-deep underground cable embedding position measuring instrument is composed of a probe and a measuring host (which is the prior art), and is connected by a signal cable.

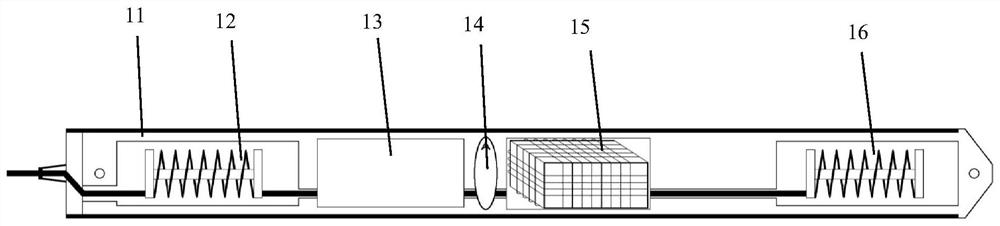

[0052] The probe provided by the present invention for the measurement of the ultra-deep underground pipeline azimuth electromagnetic calibration method is as follows: image 3 As shown, it includes a probe shell 11 , a top coil 12 inside the shell, a three-component quadrature coil set 15 , a planar electronic compass 14 , a built-in circuit board 13 and a bottom coil 16 . The top coil, bottom coil, and three-component quadrature coil set are all connected to the built-in circuit board (see Figure 5 ), the signal processing circuit on the circuit board (the built-in circuit is the prior art) carries out front-end amplification and filtering to the measurement signal of the coil, and after AD conversion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com