Automatic zooming mechanism driven by double stepping motors

A stepping motor and automatic zooming technology, applied in installation, optics, instruments, etc., can solve the problems of poor axial position accuracy of optical lens, sharp change of zooming curve of zoom system, and inability to keep clear images all the time, and achieves simple structure, high image quality and so on. Clear and ensure the effect of optical axis consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below with reference to the accompanying drawings and examples.

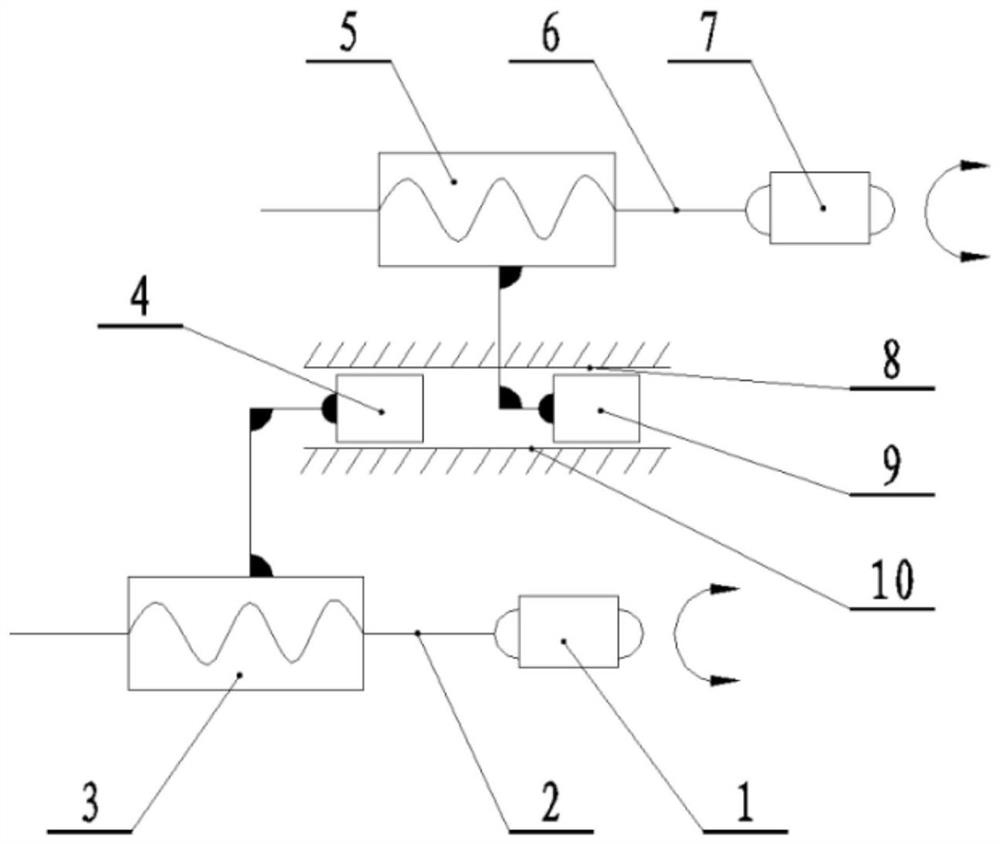

[0020] This embodiment provides an automatic zoom mechanism driven by double stepping motors, which is used to precisely position the zoom system during the zooming process, and the double stepping motors can adapt to the curvature of the zoom curve, so that the image of the optical system in the continuous zooming process Keep it clear, which solves the problem that the zoom curve of the zoom system changes sharply and the image cannot always be kept clear during the zooming process caused by poor axial position accuracy of the optical lens.

[0021] like figure 1 As shown, the zoom system adjusted by the automatic zoom mechanism includes: zoom group 4 and compensation group 9; the automatic zoom mechanism includes: zoom stepping motor 1, zoom screw 2, zoom screw nut 3, compensation screw Nut 5, compensation lead screw 6, compensation stepper motor 7 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com