Novel hydrostatic bearing

A hydrostatic bearing, a new type of technology, applied in the direction of bearings, shafts and bearings, liquid cushion bearings, etc., can solve the problems of limited use range of throttling, slow response speed of fixed throttles, etc., achieve fast and stable axial accuracy, durability The effect of strong bearing capacity and maintaining axial accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

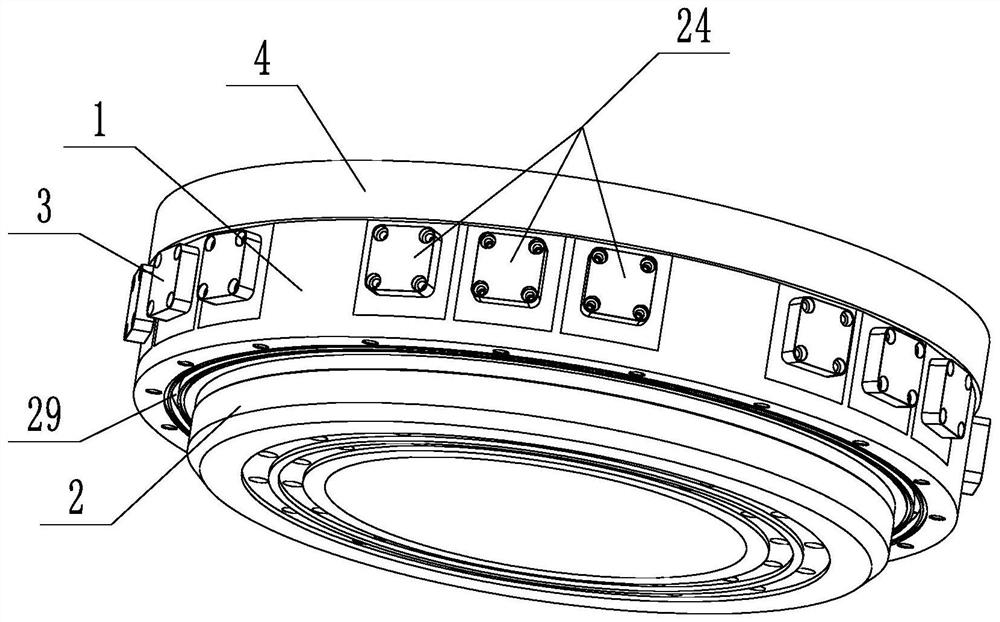

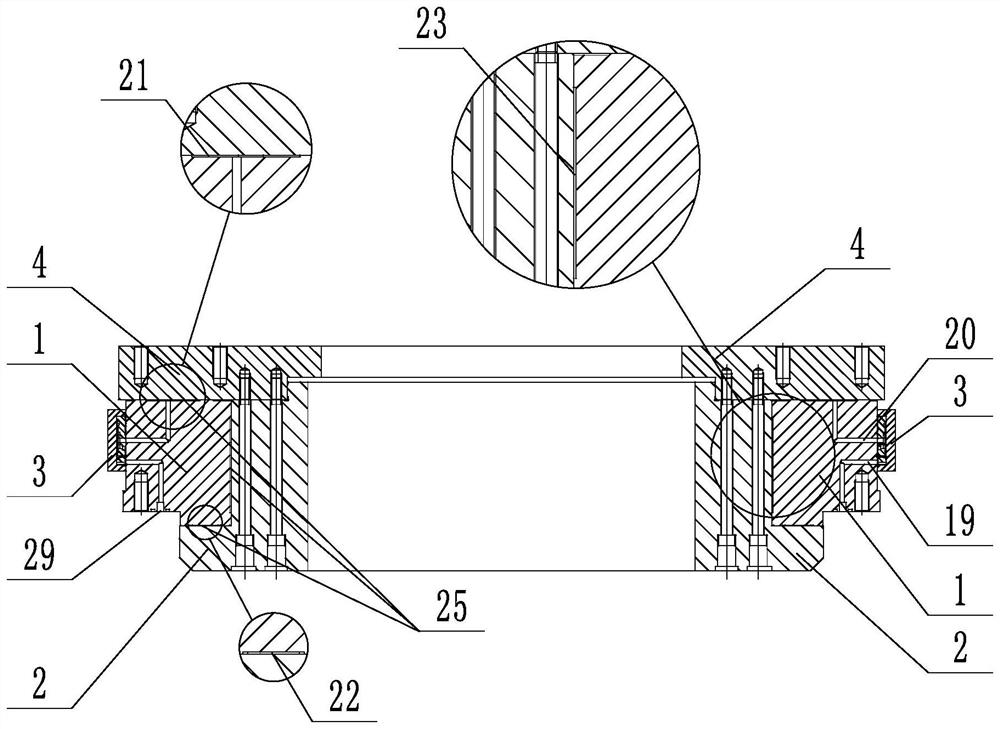

[0030] A new type of hydrostatic bearing, such as figure 1 As shown, it includes a bearing body 1, a bearing ring 2, a throttle 3 and a bearing cover 4. The throttle 3 includes a throttle cover 5 and a throttle body 6, and an oil inlet is formed between the throttle cover 5 and the throttle body 6. 7. The throttling body 6 is provided with an oil outlet 8, and the restrictor 3 is provided with a fixed throttling part 9 and a variable throttling part.

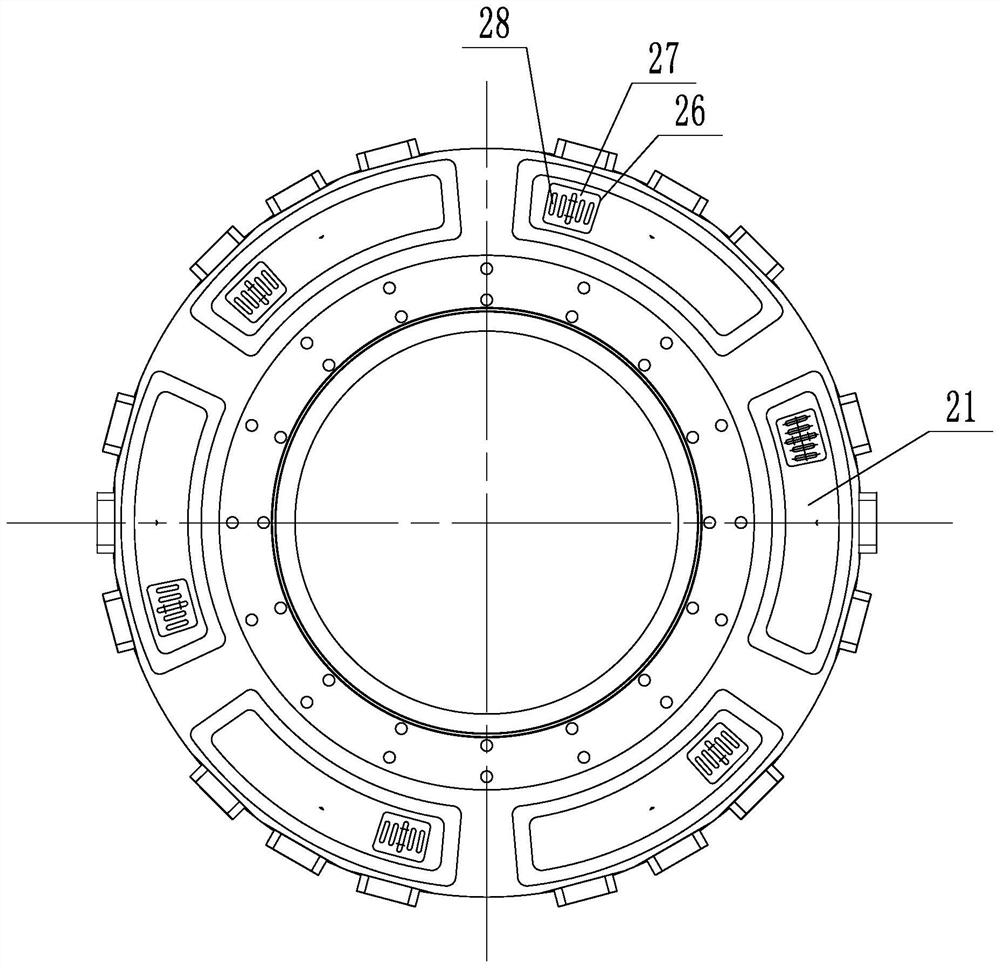

[0031] like Figure 4 , 5 As shown, the fixed throttling part 9 includes several concentrically arranged ring grooves 10, and radial grooves 11 connecting adjacent ring grooves 10, the ring grooves 10 are centered on the oil outlet 8, the ring grooves 10 and the radial grooves 11 Connect the oil inlet 7 and the oil outlet 8. The annular groove 10 and the radial groove 11 are arranged at one end of the throttling body 6 that fits the bearing body 1. The annular groove 10 and the radial groove 11 are formed by cutting on the thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com