Low-fat high-protein fermented milk and production method thereof

A production method and technology for fermented milk, which are applied to dairy products, lactobacilli, bacteria used in food preparation, etc., can solve the problems of difficulty in realizing rich milk flavor of fermented milk, affecting the flavor of fermented milk, lack of rich flavor, etc. Flavor, high protein content and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

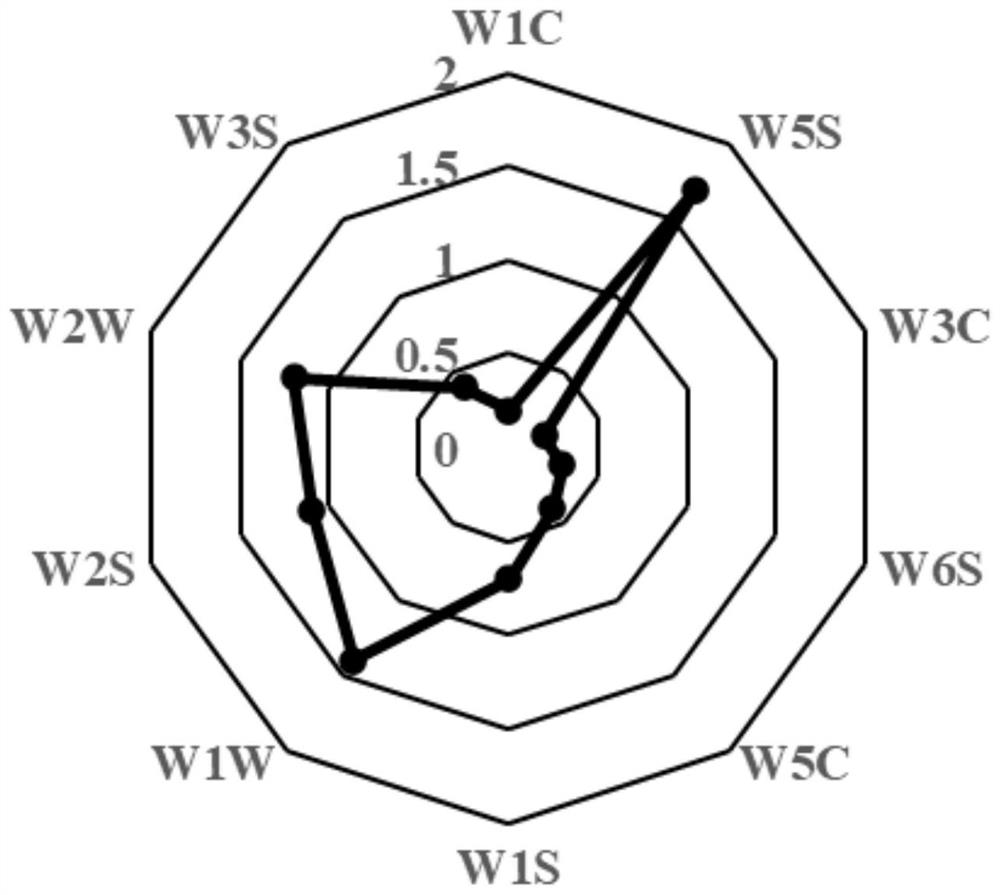

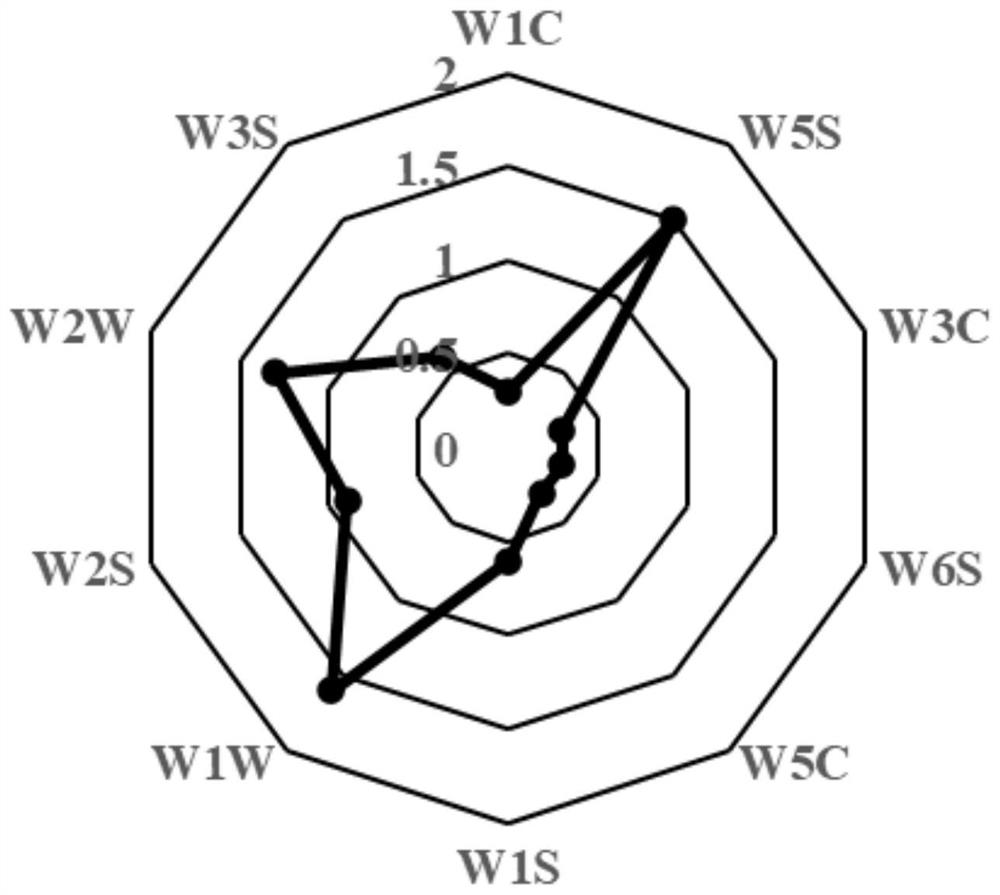

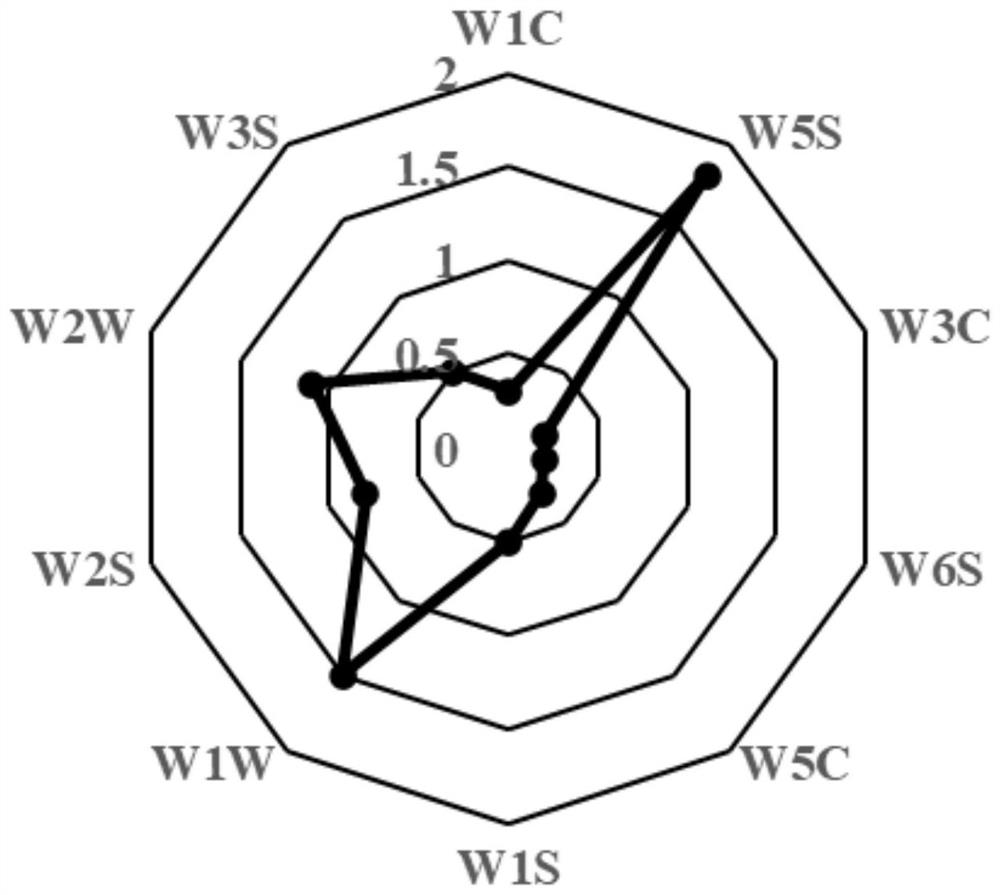

Image

Examples

Embodiment 1

[0048] A low-fat high-protein fermented milk and a production method thereof, comprising the following steps:

[0049] 1. Product formula:

[0050] Raw milk 85%, skim milk powder 15%, fermented strains 100U / T, fermented strains include Lactobacillus bulgaricus and Lactobacillus thermophiles, fat content in skim milk powder is 1%, protein content is 36%. The performance indicators of each raw material meet the requirements of conventional quality standards in this field.

[0051] Second, the specific process:

[0052] (1) Standardized degreasing treatment: This step adopts a conventional process in the field, generally to adjust milk fat and milk protein to achieve the nutritional index of the product. In this embodiment, the raw milk is degreased to obtain protein ≥ 3.1wt%, fat ≤ 0.8 wt % standardized skimmed raw milk;

[0053] (2) Homogenization and cooling: preheat the skimmed raw milk to 65°C, and homogenize under a homogenization pressure of 15MPa. Then cool to 40°C. ...

Embodiment 2

[0060] A low-fat high-protein fermented milk and a production method thereof, comprising the following steps:

[0061] 1. Product formula:

[0062] 80% raw milk, 20% skim milk powder, 80U / T fermented strains, including Lactobacillus bulgaricus and Lactobacillus thermophiles, 1% fat content and 36% protein content in skim milk powder. The performance indicators of each raw material meet the requirements of conventional quality standards in this field.

[0063] Second, the specific process:

[0064] (1) Standardized degreasing treatment: This step adopts a conventional process in the field, generally to adjust milk fat and milk protein to achieve the nutritional index of the product. In this embodiment, the raw milk is degreased to obtain protein ≥ 3.1wt%, fat ≤ 0.8 wt % standardized skimmed raw milk;

[0065] (2) Homogenization and cooling: preheat the skimmed raw milk to 65°C, and homogenize under a homogenization pressure of 15MPa. Then cool to 40°C.

[0066] (3) Hydrati...

Embodiment 3

[0072] A low-fat high-protein fermented milk and a production method thereof, comprising the following steps:

[0073] 1. Product formula:

[0074] Raw milk 75%, skimmed milk powder 25%, fermented strain 70U / T, fermented strains include Lactobacillus bulgaricus and Lactobacillus thermophiles, fat content in skimmed milk powder is 1%, protein content is 36%. The performance indicators of each raw material meet the requirements of conventional quality standards in this field.

[0075] Second, the specific process:

[0076] (1) Standardized degreasing treatment: This step adopts a conventional process in the field, generally to adjust milk fat and milk protein to achieve the nutritional index of the product. In this embodiment, the raw milk is degreased to obtain protein ≥ 3.1wt%, fat ≤ 0.8 wt % standardized skimmed raw milk;

[0077] (2) Homogenization and cooling: preheat the skimmed raw milk to 65°C, and homogenize under a homogenization pressure of 18MPa. Then cool to 40°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com