Walnut kernel baking device and method capable of improving flavor

A baking device and technology for walnut kernels, which are applied in chemical instruments and methods, edible seed preservation, and seed preservation by freezing/cooling, etc., can solve problems such as bad promotion effect, inability to maintain the flavor of walnut kernels, affecting taste and nutrition, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

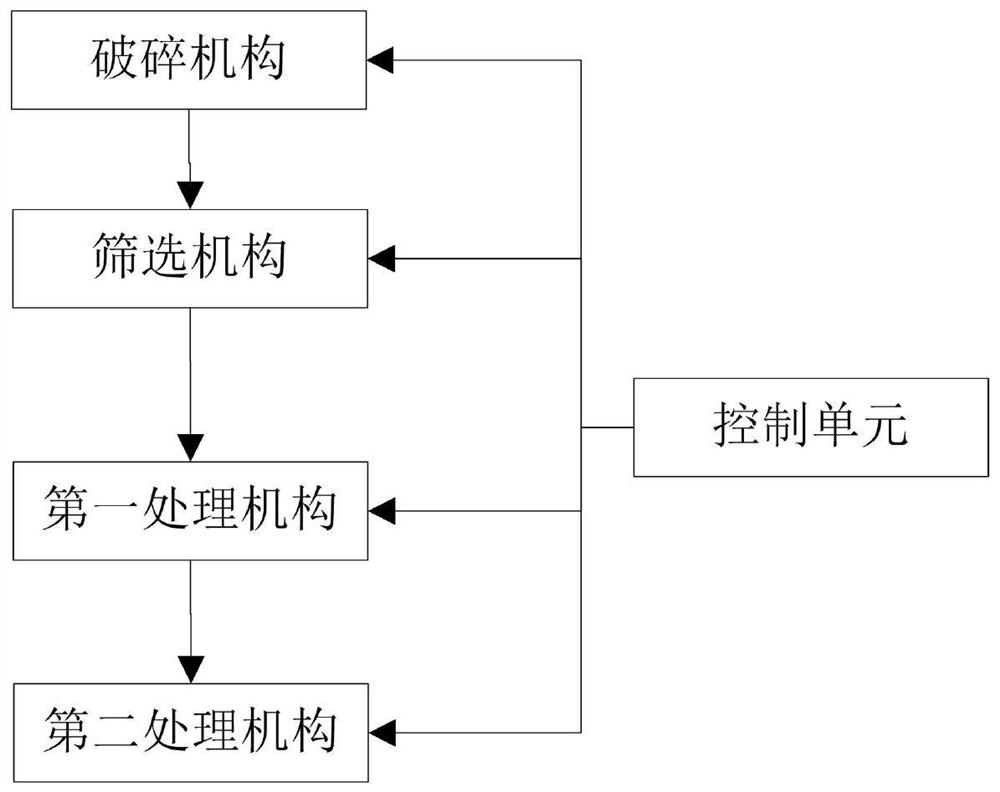

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

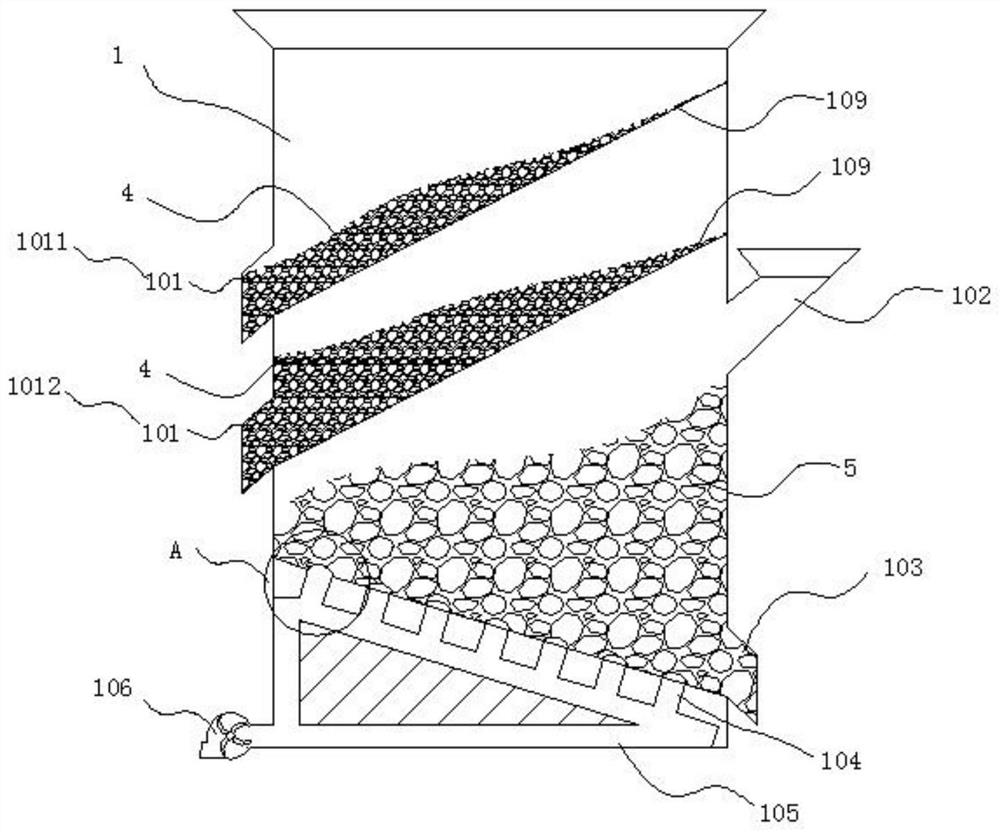

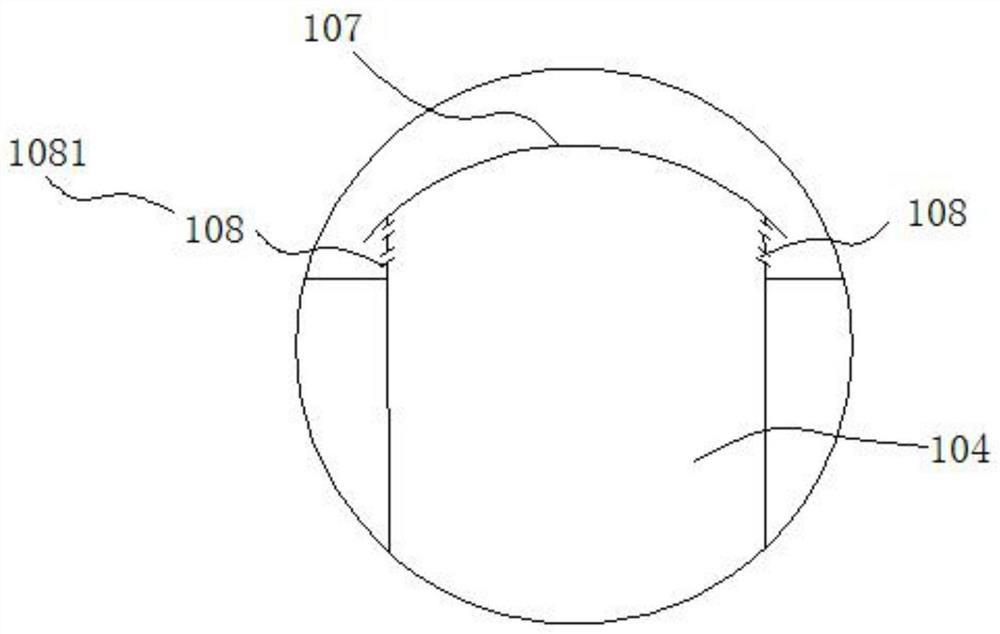

[0066]After crushing, screening and drying and roasting, configure 80kg of antioxidant solution containing 2g of antioxidant, add the antioxidant solution into the arc cavity of the cooling chamber 91 of the cooling device for processing walnut kernels, and feed 20kg of walnut kernels from the feed port 94 is sent into the cooling chamber 91 and left to stand for 4 hours. During this period, the third drive motor 2073 of the rotating shaft is turned on, and stirred 4 times at 300r / min to fully mix the antioxidant solution and the walnut kernels, and the third drive motor 2073 is turned off, and the walnuts The kernels are taken out and drained, and placed in a freeze dryer to freeze-dry until the moisture on the surface of the walnut kernels is removed, then baked and stir-fried in the first processing mechanism 2, and ensure that the first processing mechanism 2 is fried at 190°C until the moisture content 18%. Then walnuts are placed in the second processing mechanism 9, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com