Tank reactor and method for unsaturated polymer hydrogenation and nitrile rubber hydrogenation method

A tank reactor, unsaturated technology, applied in the field of hydrogenation of nitrile rubber, can solve the problems of poor continuity, rise, uneven film forming effect, etc., and achieve the effect of improving hydrogenation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

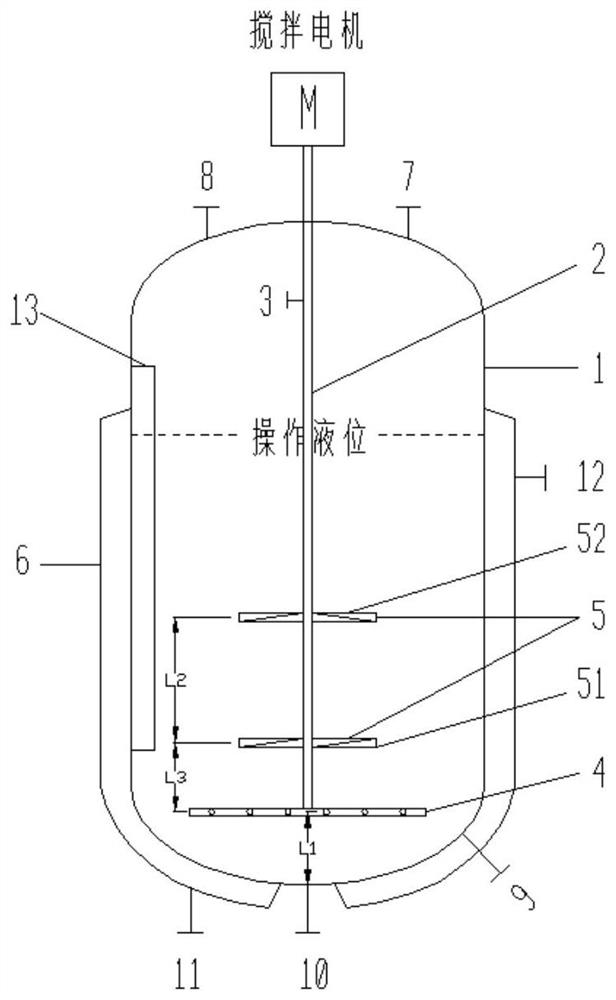

[0138] This example uses figure 1 The tank reactor shown carries out the hydrogenation reaction.

[0139] The structural parameters of the tank reactor are as follows:

[0140] (1) Cylinder:

[0141] The volume of the tank reactor is 50L, the inner diameter is 350mm, and the aspect ratio of the straight section is 1.5:1, that is, the height of the straight section is 525mm;

[0142] (2) Stirrer:

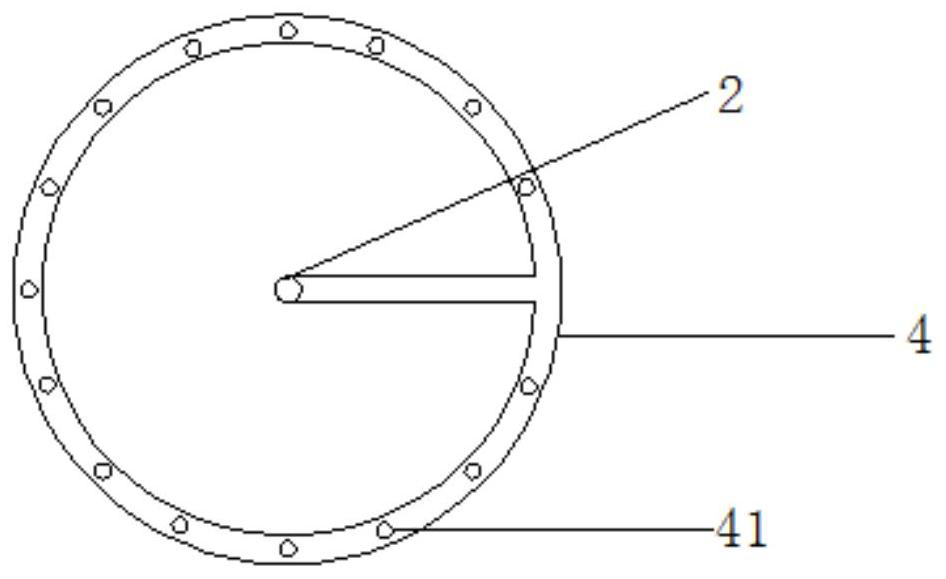

[0143] Gas distributor: at the bottom of the hollow stirring shaft, such as figure 2 The annular gas distributor shown in , the height of the annular gas distributor from the bottom inner wall of the tank reactor is 1 / 12 of the inner diameter of the tank reactor, and the ring diameter of the annular gas distributor is 1 / 12 of the inner diameter of the tank reactor 3 / 5 of the inner diameter, the number of holes is 16, and the hole diameter is 2mm;

[0144]Stirring paddles: The number of stirring paddles is 2, from the annular gas distributor upwards, the distance from the annu...

Embodiment 2

[0152] In a manner similar to Example 1, the difference is: the type of the stirring paddle is different from Example 1, specifically:

[0153] The six-half tube-blade disc turbine propeller with the same propeller diameter is used to replace the six-pitched-blade disc turbine propeller in Embodiment 1, and the position remains unchanged.

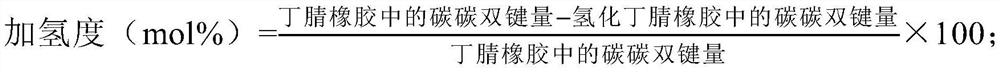

[0154] The rest are all the same as in Example 1, and samples were taken at 6 hours, 8 hours, 10 hours, and 12 hours since the reaction began to detect the degree of hydrogenation of the unsaturated polymer. The specific results are listed in Table 1.

Embodiment 3

[0156] In a manner similar to that of Example 1, the difference is that the position of the gas distributor is different from that of Example 1, specifically:

[0157] Move the hollow stirring shaft upwards so that the height of the gas distributor from the bottom inner wall of the tank reactor is 1 / 6 of the inner diameter of the tank reactor.

[0158] The rest are all the same as in Example 1, and samples were taken at 6 hours, 8 hours, 10 hours, and 12 hours since the reaction began to detect the degree of hydrogenation of the unsaturated polymer. The specific results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com