Aseptic packaging method for water purifier

A packaging method and water purifier technology, applied in packaging, transportation packaging, packaging sterilization, etc., can solve the problems of water purifier body being polluted during storage, low batch production efficiency, and water purifiers that cannot be stored for a long time , to achieve the effects of high mass production efficiency, easy operation, and simple packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

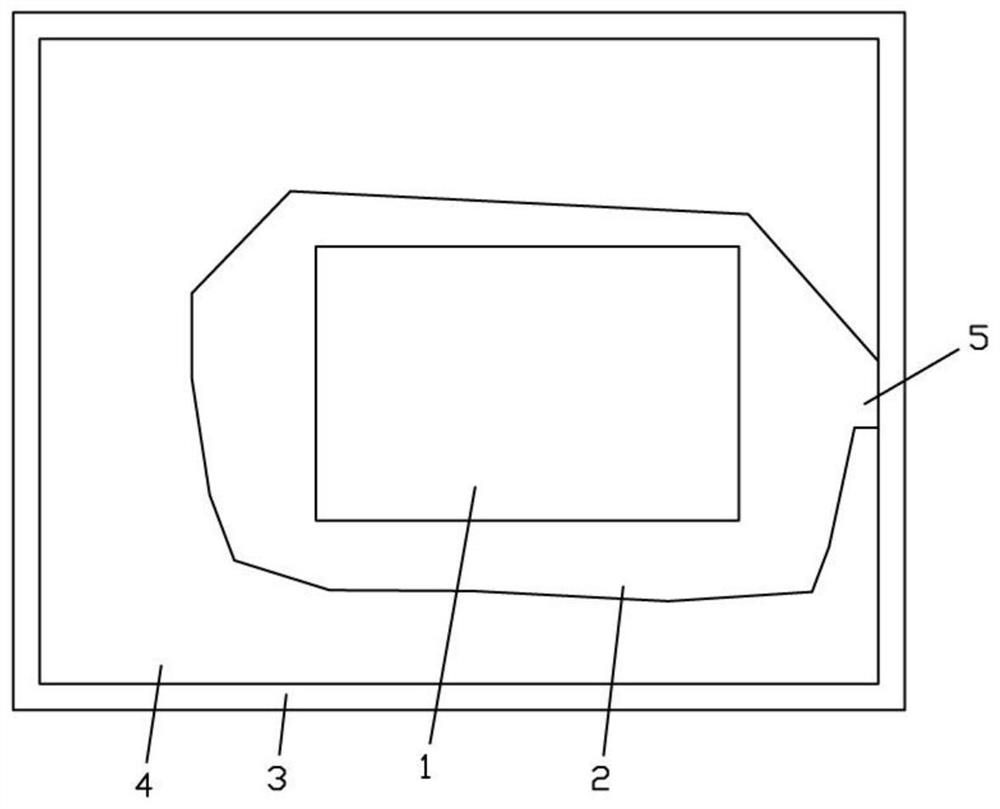

[0019] In order to better understand the present invention, the technical solution of the present invention will be further described below with reference to the accompanying drawings and examples.

[0020] like figure 1 As shown, a water purifier of the present invention is characterized in that the following steps are included:

[0021] S1: After the water purifier body 1 is completed, it is cleaned by the physical manner, including surface and internal structure cleaning;

[0022] S2: Put the water purifier body 1 after cleaning is placed in a bag 2 of the elasticity and the airtightness, and the packaging bag 2 bag 5 is pre-tightened, but the air outlet is required;

[0023] S3: The water purifier body 1 and the packaging bag 2 are loaded into the package 2 are placed in the high pressure container 3, and the bag 5 of the package 2 is fixed at the air opening of the high pressure container 3;

[0024] S4: The high pressure air is injected into the high pressure container 3 by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com