Photovoltaic module stacking anti-tilting electric transportation device

A photovoltaic module and transportation device technology, applied in transportation and packaging, packaging, internal accessories, etc., can solve the problems of high recycling cost, huge energy consumption, environmental pollution, etc., to improve safe transfer and stable fixation, and avoid excessive use. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

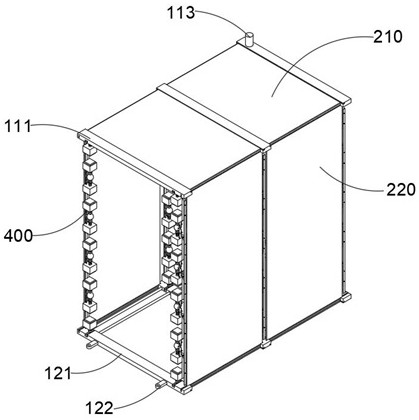

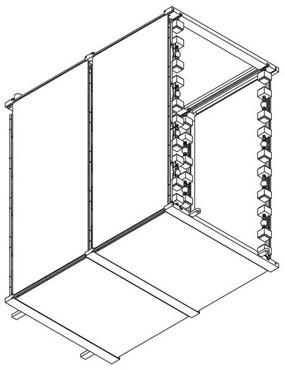

[0049] combine Figure 3-9 As shown, a photovoltaic module stacking anti-tilting electric transportation device provided by the present invention includes a fixing mechanism 100, a dustproof mechanism 200, a limit mechanism 300, and a photovoltaic clamping mechanism 400. The dustproof mechanism 200 is plugged into the fixing mechanism 100 Inside, the limit mechanism 300 is located in the fixing mechanism 100 , and in addition, the photovoltaic clamping mechanism 400 is plugged into the fixing mechanism 100 .

[0050] The fixing mechanism 100 includes a balanced top frame assembly 110 and a balanced bottom frame assembly 120, and the balanced top frame assembly 110 also includes a first frame 111, a groove 112 and a servo motor 113, and the balanced bottom frame assembly 120 also includes a second frame 121, a top frame Buckle 122, slot 123 and latch 124, dust-proof mechanism 200 includes ceiling 210 and side curtain assembly 220, position-limiting mechanism 300 comprises first...

Embodiment 2

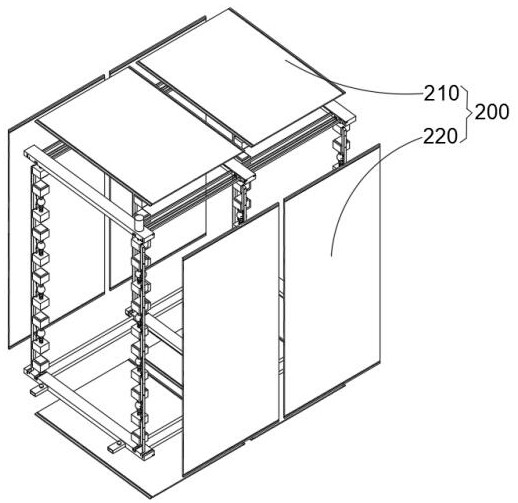

[0053] combine Figure 4 and 5 As shown, on the basis of the first embodiment, by setting the second frame 121 directly under the first frame 111, and opening slide slots in the first frame 111 and the second frame 121, multiple photovoltaic clamps can be clamped The mechanism 400, the ceiling 210 and the side curtain assembly 220 are quickly fixed. The balanced top frame assembly 110 also includes a first frame 111, a groove 112 built into the first frame 111, and a servo motor 113 installed on the top of the first frame 111.

Embodiment 3

[0055] combine image 3 As shown, in the above embodiment, by inserting the roof 210 and the side curtain assembly 220 between the first frame 111 and the second frame 121, when a plurality of solar modules are stacked, the roof 210 and the side curtain assembly 220 To protect the solar components, so as to effectively block the pollution of the solar components by external dust, the dust-proof mechanism 200 includes a ceiling 210 inserted in the first frame 111 and the second frame 121 and a 121 between the border components 220 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com