Electrical automation detection device for power distribution automation equipment

A technology of electrical automation and power distribution automation, applied in measuring devices, measuring electricity, measuring electrical variables, etc., can solve the problems of low detection efficiency, potential electric shock safety hazards, and high equipment cost, and achieve high detection efficiency and convenient card connection and drop. The effect of low-cost and low-cost equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

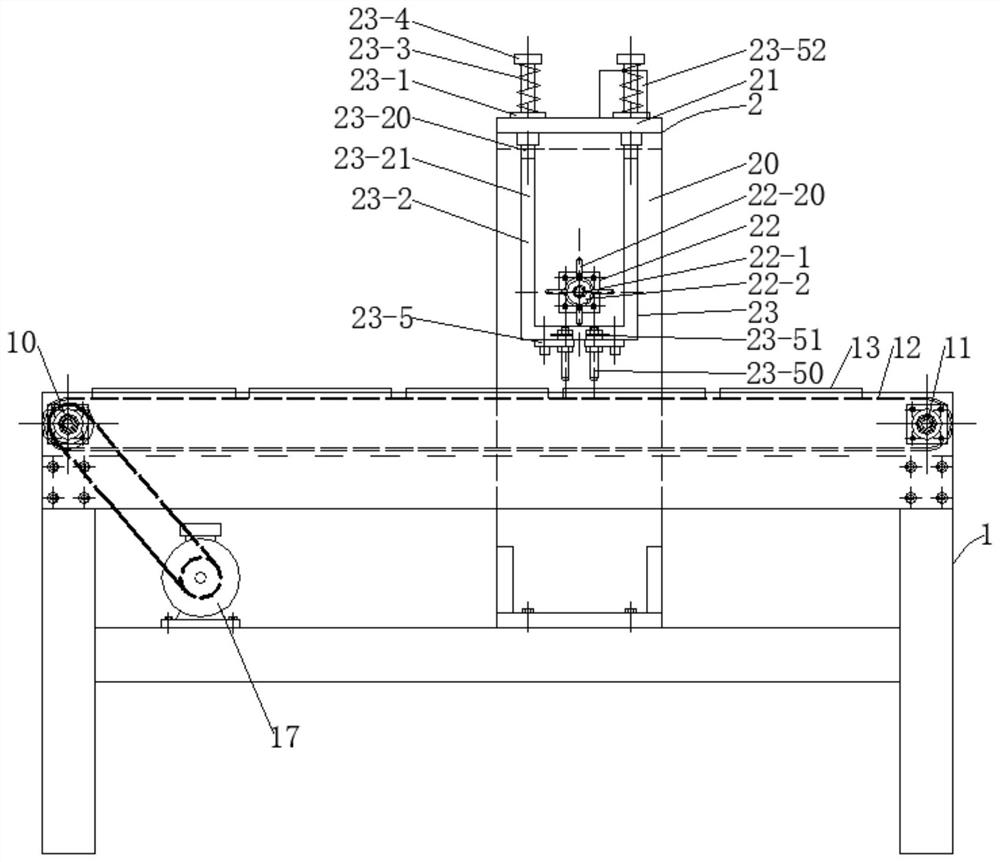

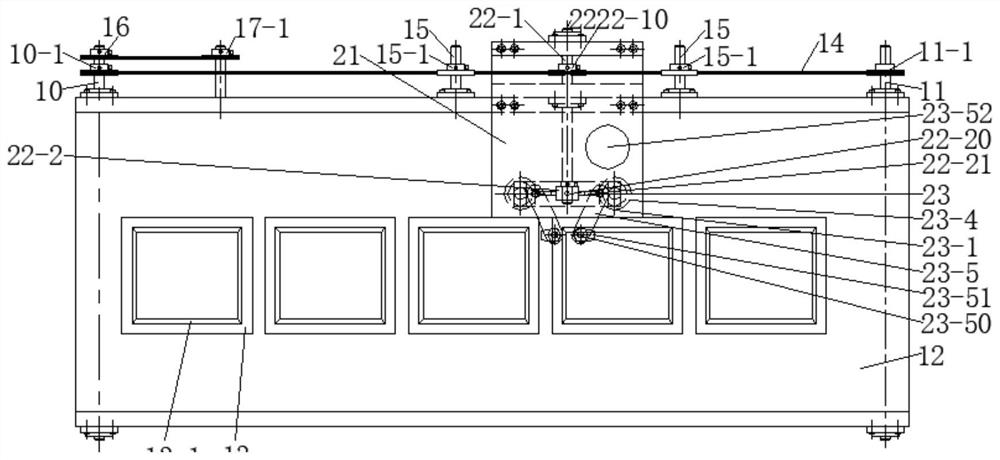

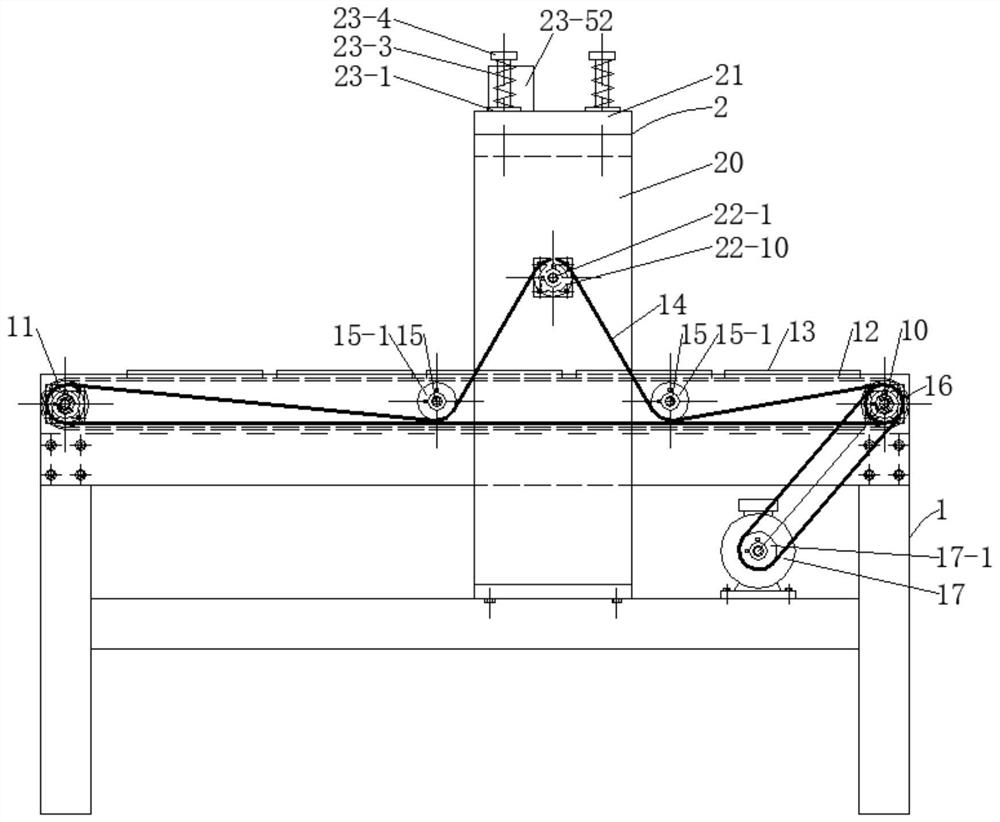

[0043] The electrical automation detection device for distribution automation equipment, the distribution automation equipment to be detected enters the equipment placement seat 13 on the conveying system 1 from the end of the assembly line, and then passes through the sprocket 6 17-1 and the chain along with the motor 17 Wheel five 16 drives the driving roller 10 to rotate, and the driving roller 10 moves with the conveyor belt structure 12 sleeved between the driving roller 10 and the driven roller 11, and the equipment placement seat 13 and the power distribution automation to be detected in the equipment placement seat 13 The equipment moves with the movement of the conveyor belt structure 12 .

[0044] At the same time, driving roller 11 drives sprocket four 22- in the rotary drive mechanism 22 by sprocket three 15-1 on sprocket one 10-1, chain 14, two fixed shafts 15, sprocket two 11-1 10 rotates, and the sprocket four 22-10 drives the rotating disk 22-2 to rotate throug...

Embodiment 2

[0047] On the basis of Embodiment 1, the inner frame of the device placement seat 13 is provided with a chamfer 13-1, which facilitates the clamping and landing of the power distribution automation equipment to be detected, and ensures that the metal needle 23-50 is in contact with the device to be detected. Contact stability of metal contacts on distribution automation equipment.

[0048] An even number of threaded holes 22-20 are evenly arranged on the circumference of the rotating disk 22-2, and a driving rod 22-21 is screwed on the threaded hole 22-20, and the driving rod 22-21 is screwed into the depth of the threaded hole 22-20 Adjustable, realizes the adjustment of the U-shaped frame 23-2 moving up and down with the metal needle 23-50 through the detection frame 23-5, and ensures the detection of different power distribution automation equipment to be detected.

[0049] The upper part of the U-shaped frame 23-2 is a cylindrical rod 23-20, the lower part is a U-shaped pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com