Automatic phosphorus preparation device for phosphorus copper processing

A power device and phosphor bronze technology, which is applied in the field of automatic phosphorus distribution device for phosphor bronze processing, can solve the problems of reduced precision, precision, performance degradation, environmental pollution, etc., and achieves the effect of solving the easy volatilization of phosphorus and improving the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

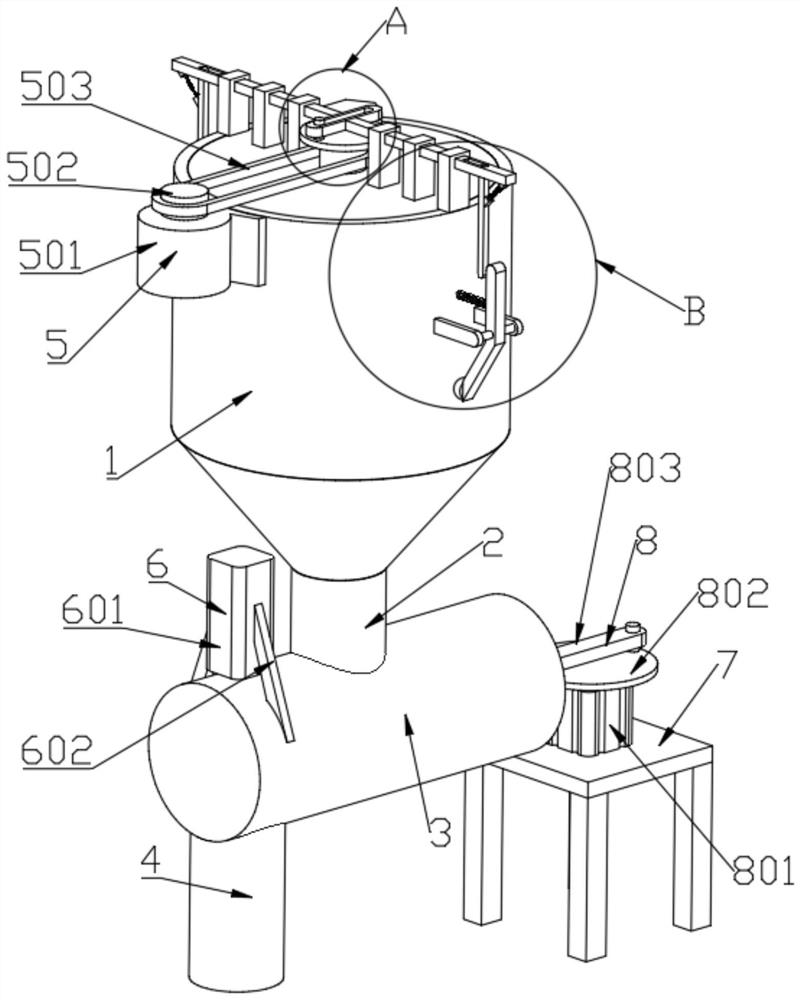

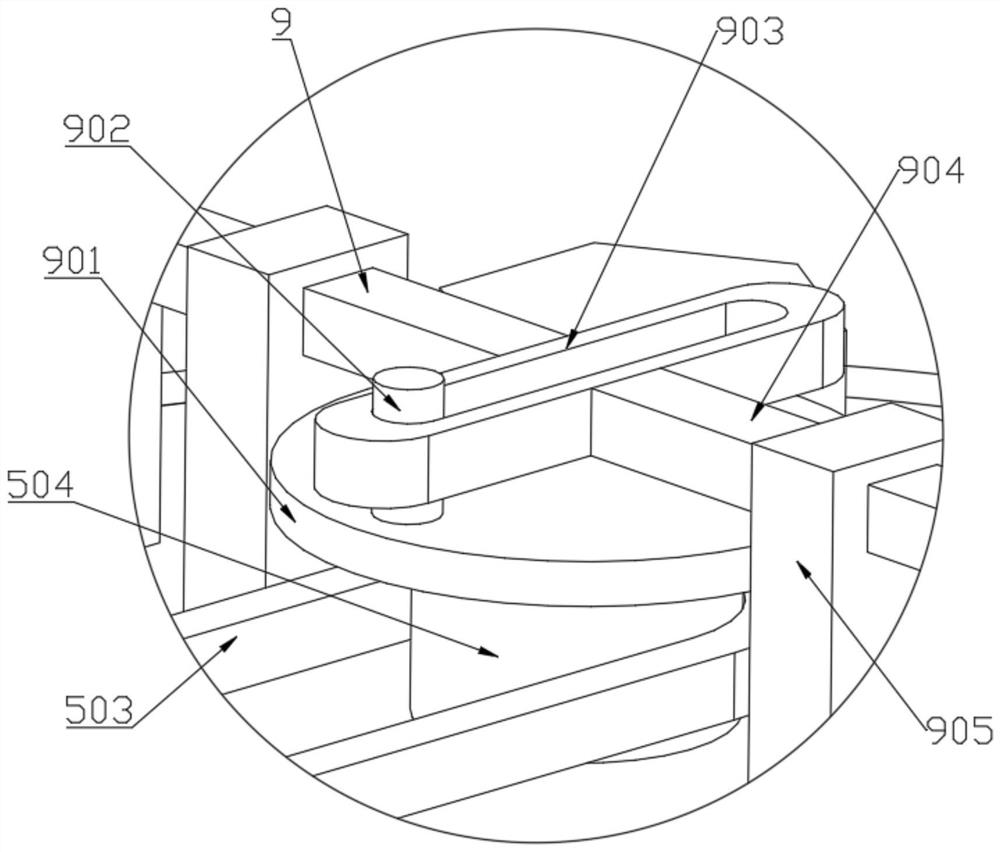

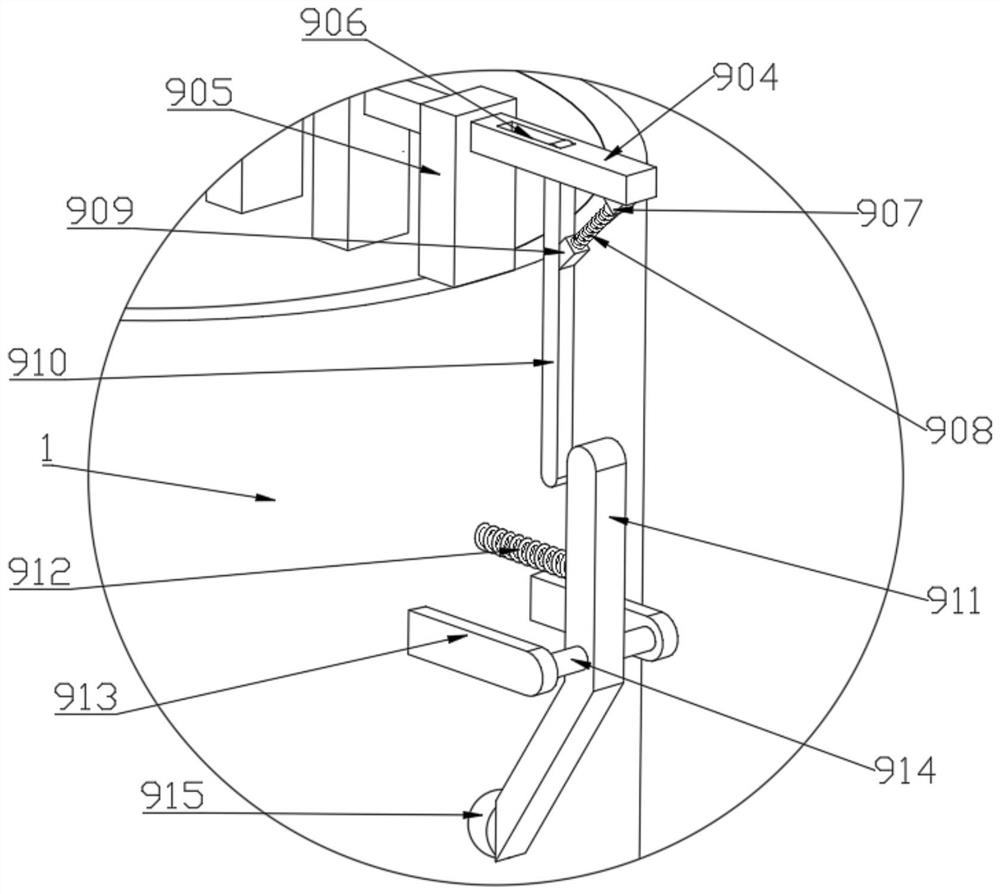

[0029]As a further embodiment of the present invention: the power unit 5 includes a first motor 501, a driving wheel 502, a belt 503 and a driven wheel 504, and is fixedly connected between the first motor 501 and the storage tank 1, and the output shaft of the first motor 501 The driving wheel 502 is fixedly connected with the driving wheel 502, and the driving wheel 502 is connected with the driven wheel 504 through the belt 503. During work, by turning on the first motor 501, the driving wheel 502 will be rotated at this time, and then driven by the belt 503. The driving wheel 504 rotates, which provides power for the conveying device 11 and the knocking device 9 .

[0030] As a further embodiment of the present invention: the conveying device 11 includes a fixed frame 1101, an auger 1102, a bearing seat 1103, a rotating shaft 1104 and a scraper 1105, the rotating shaft 1104 is connected to the storage tank 1, and the rotating shaft 1104 is connected to the driven wheel 504...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com