Defrosting device, air conditioner and defrosting method

A technology for air conditioners and outdoor unit heat exchangers, which is applied in air conditioning systems, space heating and ventilation, heating methods, etc., and can solve problems such as increased energy consumption, difficulty in cleaning frost layers, and thick frost layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

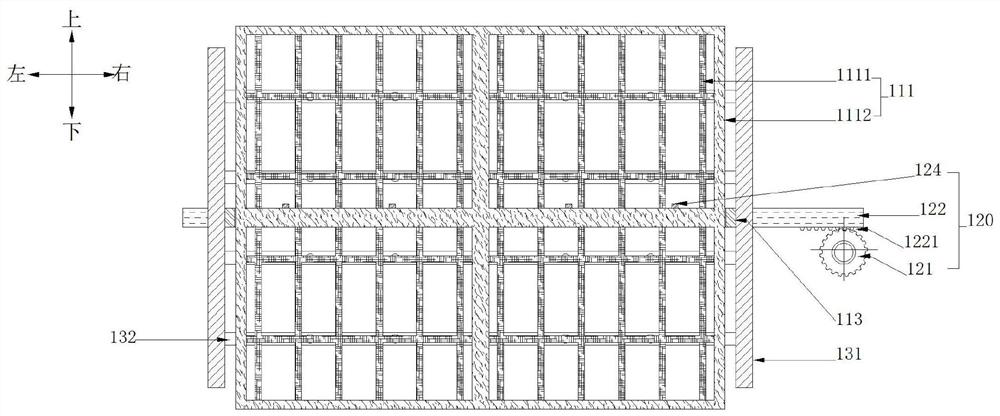

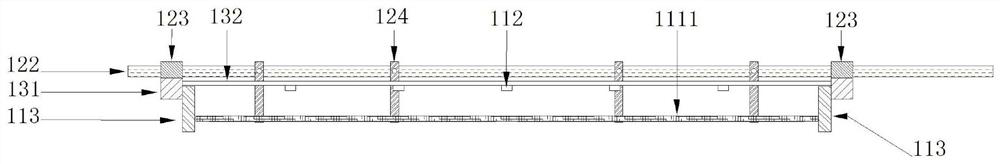

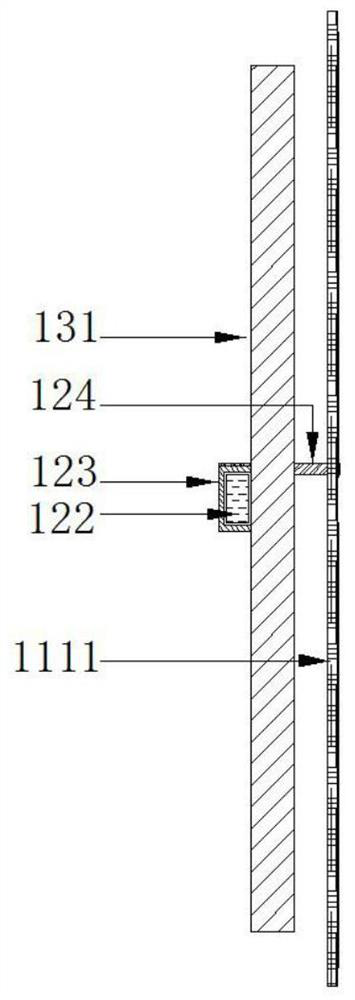

[0060] A defrosting device 100, the defrosting device is arranged adjacent to the outdoor unit heat exchanger 210, including a defrosting module 110 and a support protection module 130, the defrosting module 110 includes an ultra-black carbon airgel unit 111 and a light emitting unit 112, the light emitting unit The light energy emitted by 112 is directly irradiated on the ultra-black carbon airgel unit 111; the support protection module 130 is arranged on the outside of the defrosting module 110, and is connected with the shell 220 of the outdoor unit 200 for supporting and protecting the defrosting module 110. protection.

[0061] The ultra-black carbon airgel unit 111 includes an ultra-black carbon airgel network 1111 and an ultra-black carbon airgel skeleton 1112 , and the ultra-black carbon airgel mesh 1111 is arranged on the ultra-black carbon airgel skeleton 1112 .

[0062] The light emitting unit 112 is disposed on the supporting protection module 130 .

[0063] The l...

Embodiment 2

[0077] The defrosting device in Example 1 can be used to defrost the heat exchanger of the outdoor unit alone, but in order to shorten the defrosting time and improve the defrosting effect, it is used together with the reverse cycle defrosting, and the defrosting effect is better. The embodiment specifically describes the defrosting method used in combination with the two defrosting methods.

[0078] see Figure 7 The schematic flow chart of the shown defrosting method, a defrosting method, includes the following steps:

[0079] Step Z100, after the air conditioner enters the reverse cycle defrosting mode, obtain the continuous running time Δt of the reverse cycle defrosting mode;

[0080] The reverse cycle defrosting mode means that when the air conditioner meets the defrosting conditions, the compressor stops running, the four-way valve changes direction, the compressor restarts, and the air conditioner enters the reverse cycle defrosting mode.

[0081] Step Z200, when the...

Embodiment 3

[0093] The defrosting method in this embodiment is different from the defrosting method in Embodiment 2 in that: the energizing current of the light emitting unit 112 can be adjusted according to the actual defrosting conditions.

[0094] see Figure 8 The schematic flow chart of the shown defrosting method, a defrosting method, includes the following steps:

[0095] Step S100, after the air conditioner enters the reverse cycle defrosting mode, obtain the continuous operation time Δt of the reverse cycle defrosting mode;

[0096] The reverse cycle defrosting mode means that when the air conditioner meets the defrosting conditions, the compressor stops running, the four-way valve changes direction, the compressor restarts, and the air conditioner enters the reverse cycle defrosting mode.

[0097] Step S200, when the continuous running time Δt is greater than or equal to the first preset time Δt 1 , that is, Δt≥Δt 1 , the defrosting device 100 starts to run, makes the ultra-b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com