Drying assembly and refrigeration equipment

A drying and component technology, used in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of unbalanced distribution and unbalanced cooling effect, and achieve the effect of balanced cooling effect, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

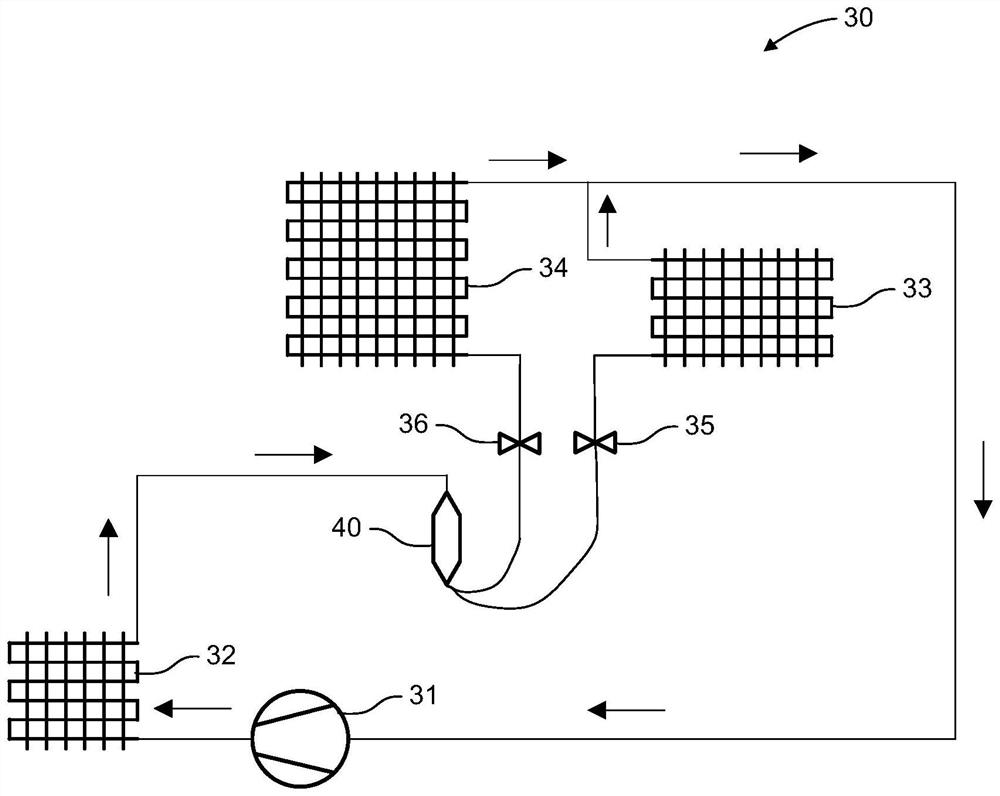

[0031] In the existing refrigeration equipment, when the refrigerant enters multiple capillaries after being filtered by the drying tube, the distribution in each capillary is often very unbalanced. Some capillaries are dominated by liquid-phase refrigerants, and some capillaries are dominated by gas-phase refrigerants. Mainly, resulting in unbalanced cooling effect of each compartment in the refrigeration equipment.

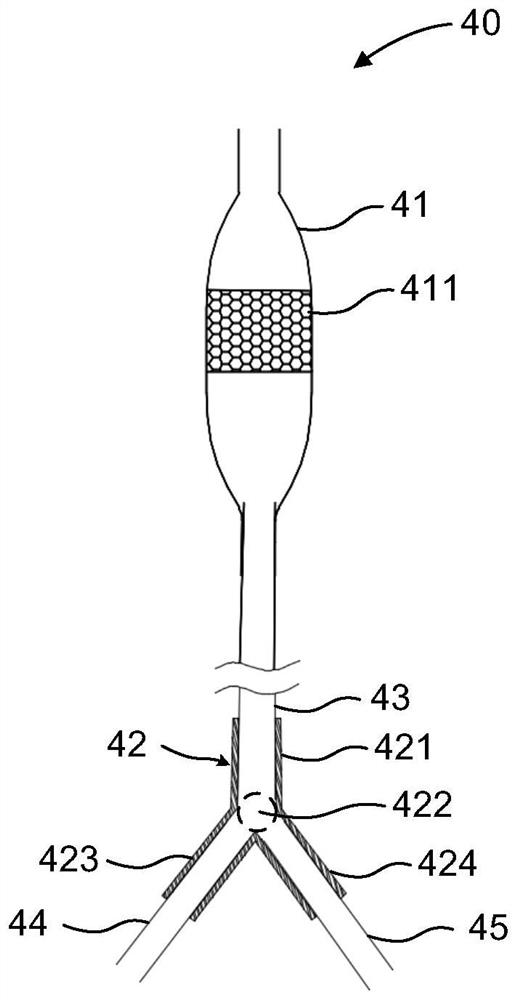

[0032] Different from the prior art, in the technical solution provided by the embodiment of the present invention, the drying assembly includes: a drying pipe, which is suitable for drying the refrigerant; a flow divider, which communicates with the drying pipe and divides the refrigerant from the drying pipe so that The refrigerant flows into at least two output branches respectively in the state of liquid phase, gas phase or gas-liquid two-phase.

[0033] Compared with the prior art, the drying assembly provided by the embodiment of the present invention can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com