A preparation method of perovskite/mwt heterojunction series-parallel composite battery

A tandem battery and composite battery technology, applied in semiconductor/solid-state device manufacturing, circuits, photovoltaic power generation, etc., can solve the problem of difficulty in breaking the efficiency limit, and achieve the effect of reducing the risk of falling off, reducing metal shading, and high stacking efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

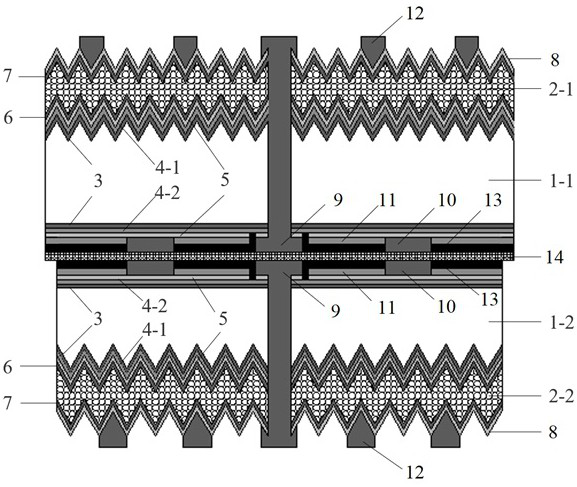

[0054] The invention provides a perovskite / MWT heterojunction series-parallel composite battery structure ( figure 1 ), the structure consists of upper and lower layers of perovskite / MWT heterojunction cells connected in parallel through the middle metal lead welding. Conductive leads" exposed.

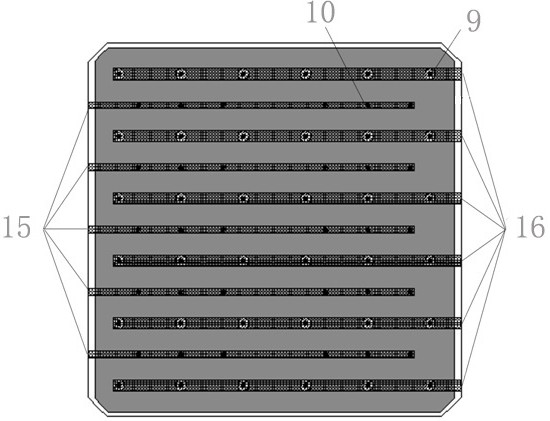

[0055] Among them, the perovskite / MWT heterojunction tandem battery is formed by superimposing the perovskite battery on the MWT heterojunction battery. The front current is collected to the back negative electrode point through the plugging electrode, and the back cover is in contact with the positive electrode point and is in contact with the negative electrode point. The back electrode layer with pole isolation, print a layer of insulating film on the back electrode layer, only expose the positive electrode point and the negative electrode point to contact with the "metal conductive lead", and the "metal conductive lead" is on the back edge of the upper battery (the width is about ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com