Heat dissipation device

A heat dissipation device and heat dissipation fin group technology, applied in indirect heat exchangers, lighting and heating equipment, cooling/ventilation/heating transformation, etc., can solve problems such as difficulty in heat dissipation, and achieve large effective contact area and expanded condensation area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

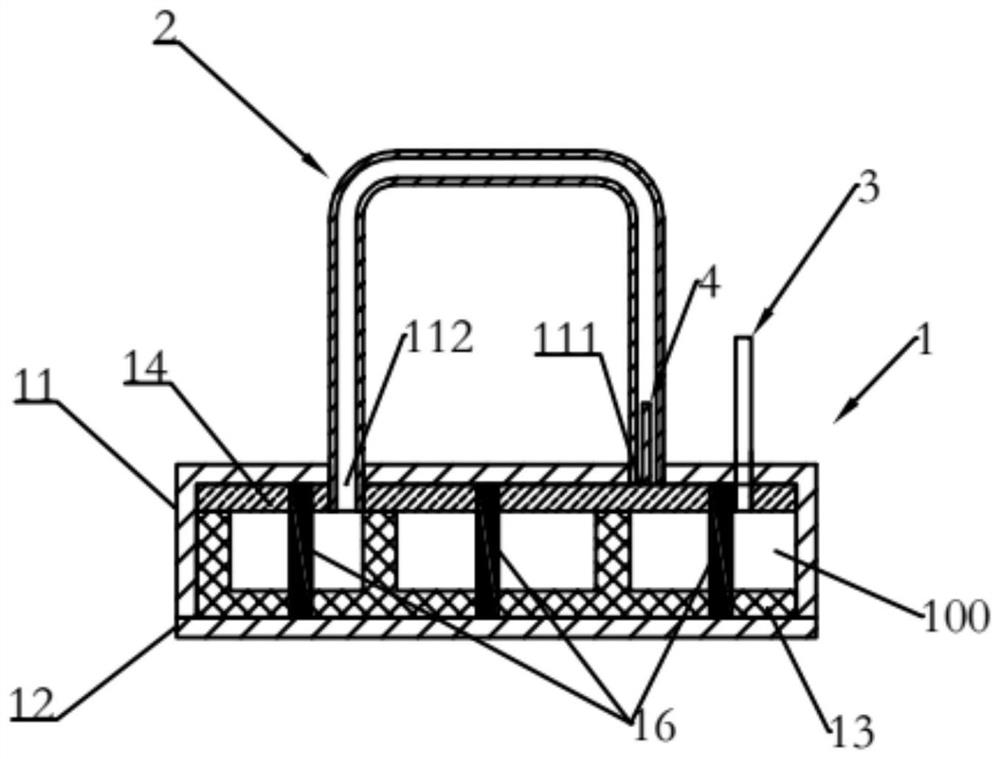

[0037] see image 3 , is a cross-sectional view of the second embodiment of a heat dissipation device of the present invention. As shown in the figure, the chamber 100 has a first capillary tissue 13 , a second capillary tissue 14 , a third capillary tissue 15 and a support body 16 . The third capillary tissue 15 contacts or connects with the first capillary tissue 13 and the second capillary tissue 14 respectively, so as to realize the indirect contact or connection between the first capillary tissue 13 and the second capillary tissue 14 . The third capillary structure 15 can be selected as any one or a composite structure of wire mesh, metal foam, metal felt, fiber bundle, and powder porous structure. In order to increase the condensation area and strengthen the heat exchange effect, the outer surface of the upper cover 11 of this embodiment is provided with a second cooling fin group 6 (shown in the figure), but it is not limited, and it can also be installed on the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com