Cooking control method and device of cooking utensil, storage medium and cooking utensil

A technology for cooking utensils and control methods, applied in the field of storage media, cooking utensils, cooking utensil cooking control methods, and devices, capable of solving problems such as unevenness, low detection accuracy, and easy overflow of millet, and achieving the effect of rapid heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

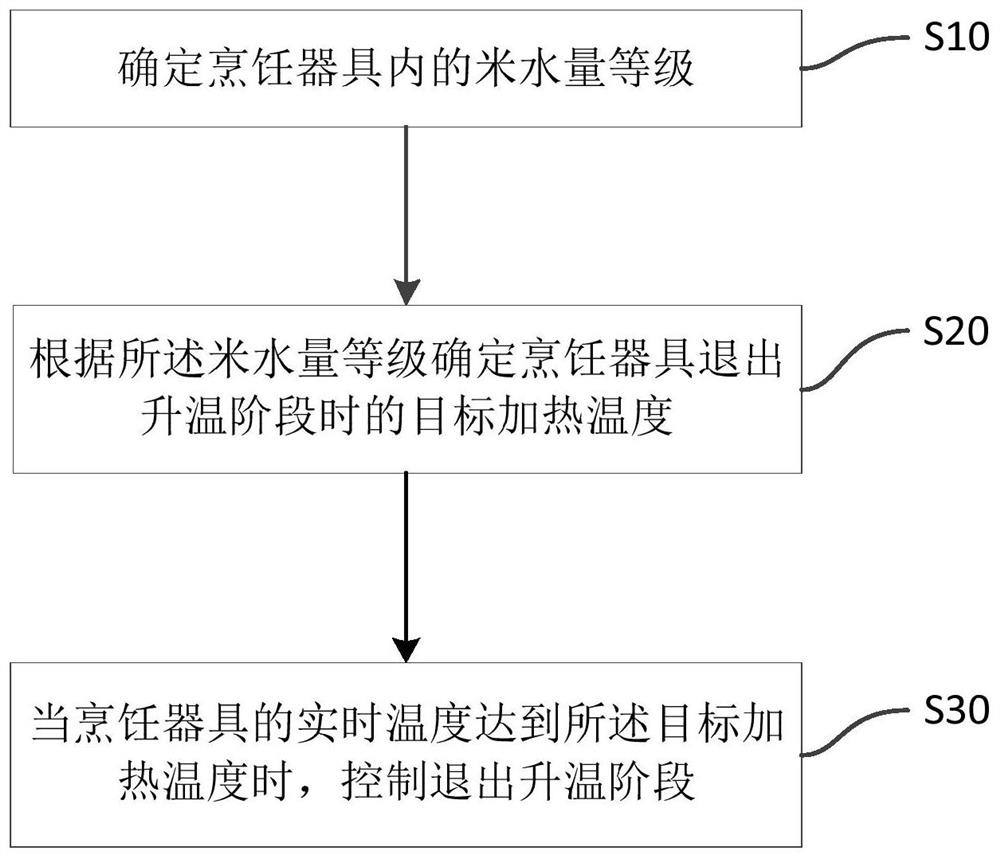

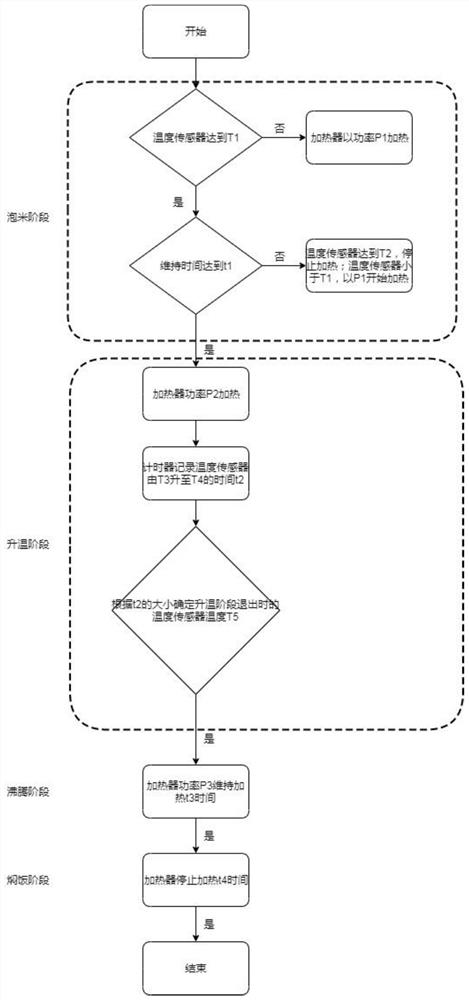

[0092] Embodiment one: if figure 2 As shown, the cooking process includes a rice soaking stage, a heating stage, a boiling stage and a stewing rice stage.

[0093] 1. The rice cooker starts to work and enters the cooking mode;

[0094] 2. Rice soaking stage: the heating component is heated with power P1 (≥80% of rated power), and when the real-time temperature detected by the temperature sensor is greater than or equal to T1 (25°C ~ 35°C), the temperature detected by the temperature sensor is heated with power P1 The real-time temperature is maintained between temperature T2 (30°C-45°C) and temperature T1, wherein T2 is greater than T1. When the maintenance time of this stage reaches t1 (0-20min), exit the soaking rice stage and enter the heating stage. The rice soaking stage is mainly to allow the rice grains to fully absorb water and ensure that they are heated more evenly during cooking.

[0095]3. Heating stage: the heating component is heated with power P2 (≥80% rated...

Embodiment 2

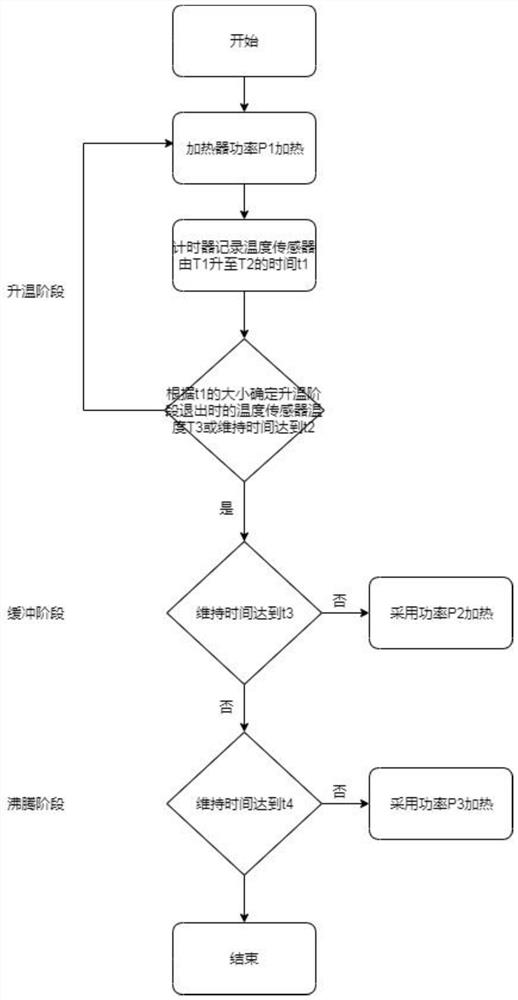

[0099] Embodiment two: if image 3 As shown, the cooking process includes a heating phase, a buffering phase and a boiling phase.

[0100] 1. Start working and enter the porridge cooking mode;

[0101] 2. Heating stage: the rice cooker uses power P1 (≥80% of rated power) to heat the rice cooker to rapidly increase the temperature of the rice-water mixture, and the timer records the real-time temperature detected by the temperature sensor from T1 (40°C to 50°C) to T2 ( 50℃~80℃) time t1 (5~20min). Use the time t1 required for the rice-water mixture to rise from temperature T1 to temperature T2 detected by the temperature sensor during the heating process of the cooking utensil to distinguish different rice water amounts. Usually, t1 is proportional to the amount of rice water. Wherein, T2 is lower than the target heating temperature T3 (70-90° C.) exiting the heating stage. In addition, for a cooking appliance equipped with a weight detection sensor, the weight m of the rice-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com