Heart valve prosthesis, artificial valve formed by heart valve prosthesis and preparation method of artificial valve

A heart valve and prosthesis technology, applied in the field of heart valve prosthesis and its artificial valves and preparations, can solve the problems of unsatisfactory demand, prosthesis failure material and shape, etc., to reduce compliance mismatch and reduce stress Concentrated, less prone to stress fatigue effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

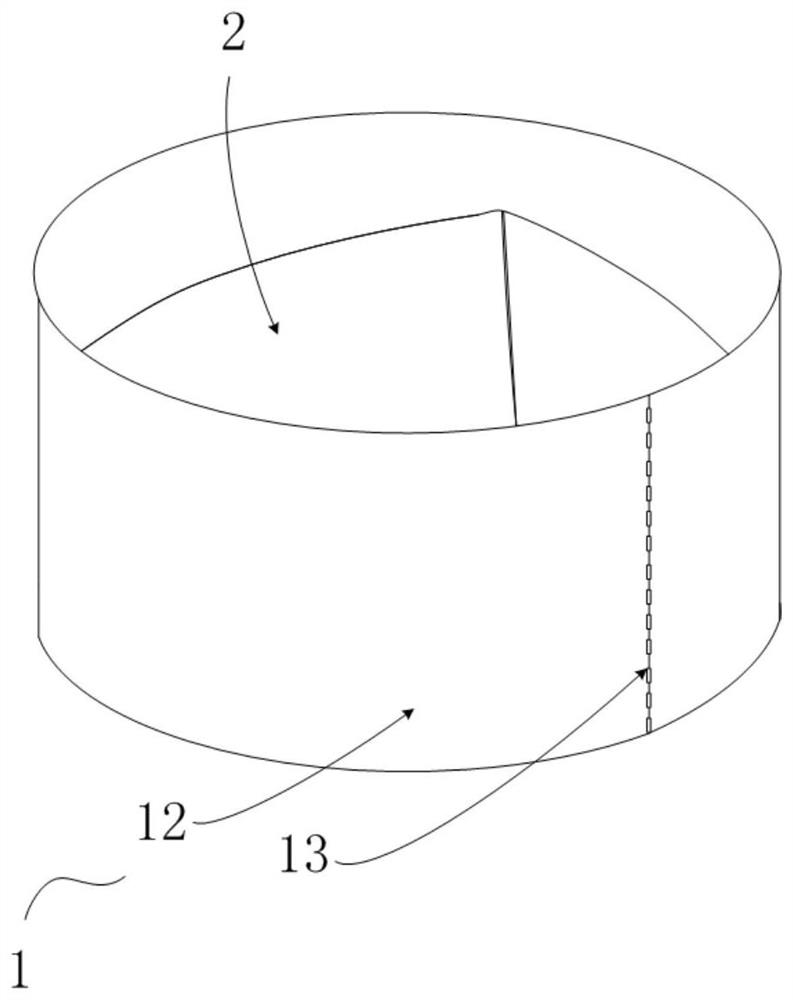

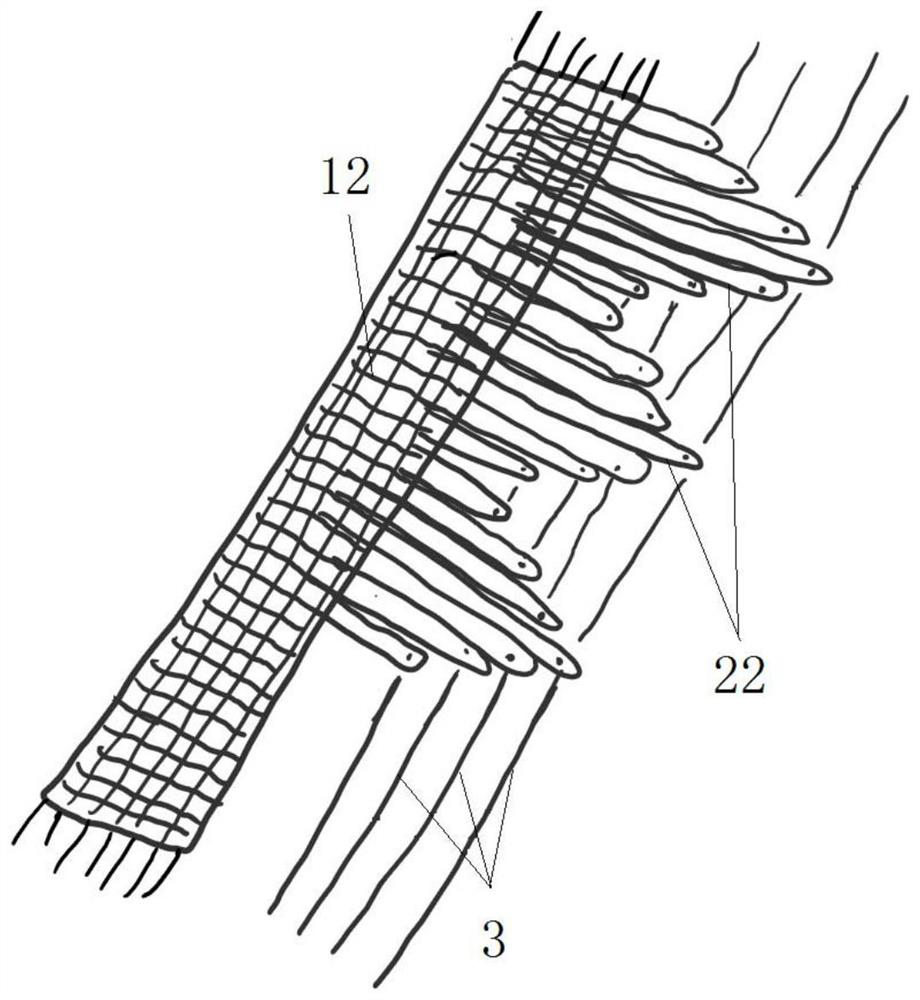

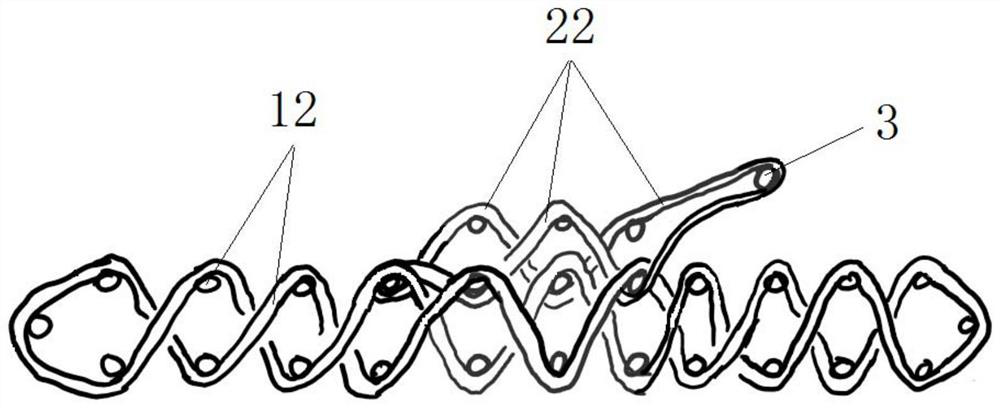

[0060] A heart valve prosthesis, such as figure 1 As shown, it includes a support element 1 in a tubular structure, and several leaflets 2 connected to the inner wall of the support element 1; The other two sides on 12 are fixed to each other to form sutures 13 of tubular structure; the leaflet 2 is composed of several leaflet layers stacked; the opposite sides of the leaflet 2 are the interweaving side and the free side respectively, and the interweaving side It is fixed between the two selvedges of the outer layer fabric 12 by a weaving method, and the free side is the selvedge.

[0061] The selvedge mentioned in the present invention is the edge formed after the warp thread loops back to the weaving area at the most edge weft thread to continue weaving, or the edge formed after the weft thread loops back to the weaving area at the most edge warp thread to continue weaving. The middle part of the selvedge has no ends, and the thread ends only exist at the two ends of the ed...

Embodiment 2

[0078] This embodiment provides another method for preparing a heart valve prosthesis. The structure of the prepared heart valve prosthesis is basically the same as in Example 1, the difference is that the material of the inner weft 22 in this embodiment is the same as that of the outer fabric 12. Similarly, in the preparation method, the difference is that when the outer weft and the outer warp are woven together, the outer weft is also used to weave the inner weft 22 at the same time. Concrete preparation process is as follows:

[0079] Step 1. Arranging several yarns made of PET to form outer warps, setting interweaving areas on the outer warps, setting a number of grasping ropes 3 above the outer warps, and adopting a yarn made of PET as the outer weft and interlacing the outer warps Weaving, and when weaving to the interweaving area, the yarn that constitutes the outside weft is extended and fixed on one of the grabbing ropes 3 and then returns to the interweaving area, a...

Embodiment 3

[0083] An artificial valve, comprising the heart valve prosthesis prepared in Example 1 or Example 2, and a bracket installed on the heart valve prosthesis. After the heart valve prosthesis in this embodiment is prepared, it can be processed by any post-processing technology such as thermoforming, insert molding, ultrasonic welding, solvent treatment, scouring (cleaning with solvent), etc., to construct the final geometric shape, After the construction is completed, it can be fixed with the bracket. Appropriate brackets specially designed for heart valves are fixed at the seamless connection position between the leaflet 2 and the support element 1 . The method of fixing the stent on the heart valve prosthesis depends on the geometry of the stent and the structure of the heart valve prosthesis, and the ways of fixing the heart valve prosthesis to the stent include but are not limited to suture, welding, adhesive bonding Together and so on. With the heart valve prosthesis prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com