Forming device for veneer wallboard production and production method thereof

A molding device and wallboard technology, which is applied to supply devices, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of increasing labor intensity of workers, large differences in mechanical properties of wallboards, and unrepresentativeness, etc. Labor efficiency, easy sampling and testing, and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

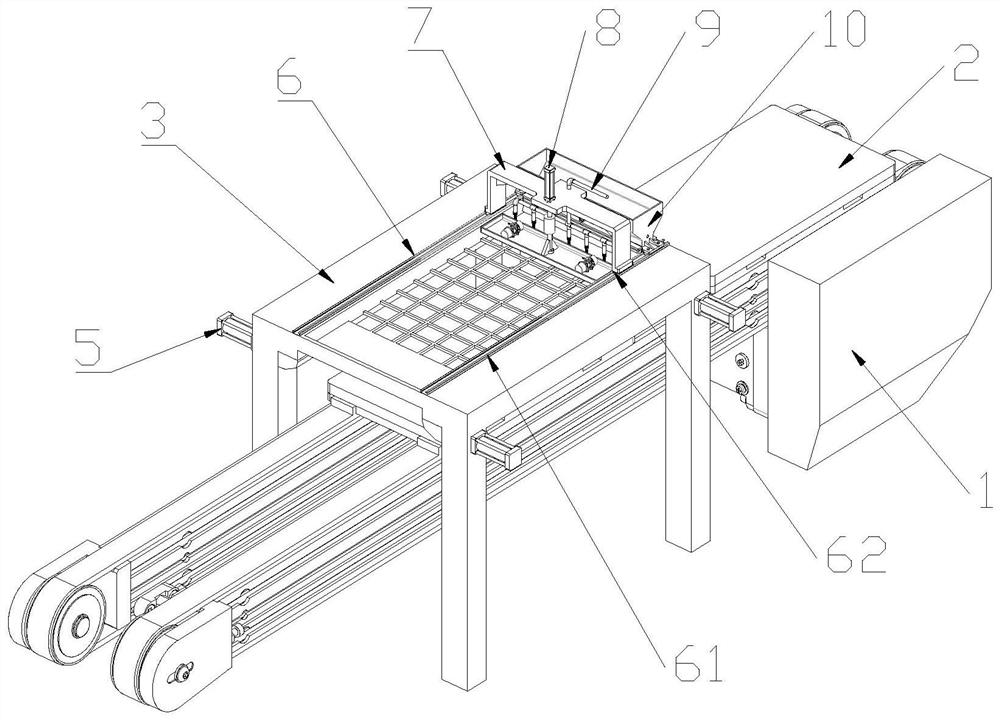

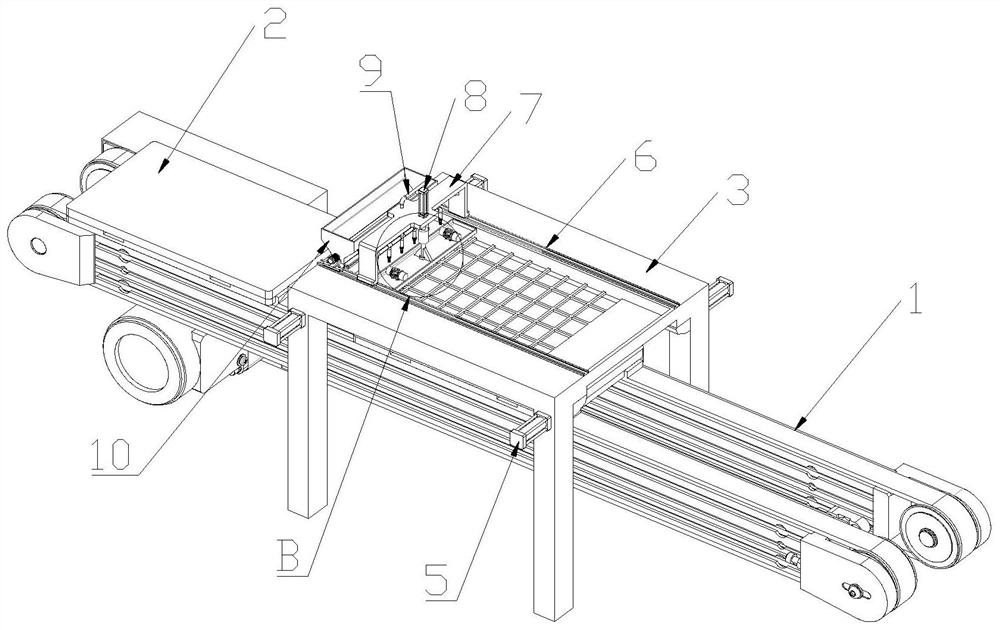

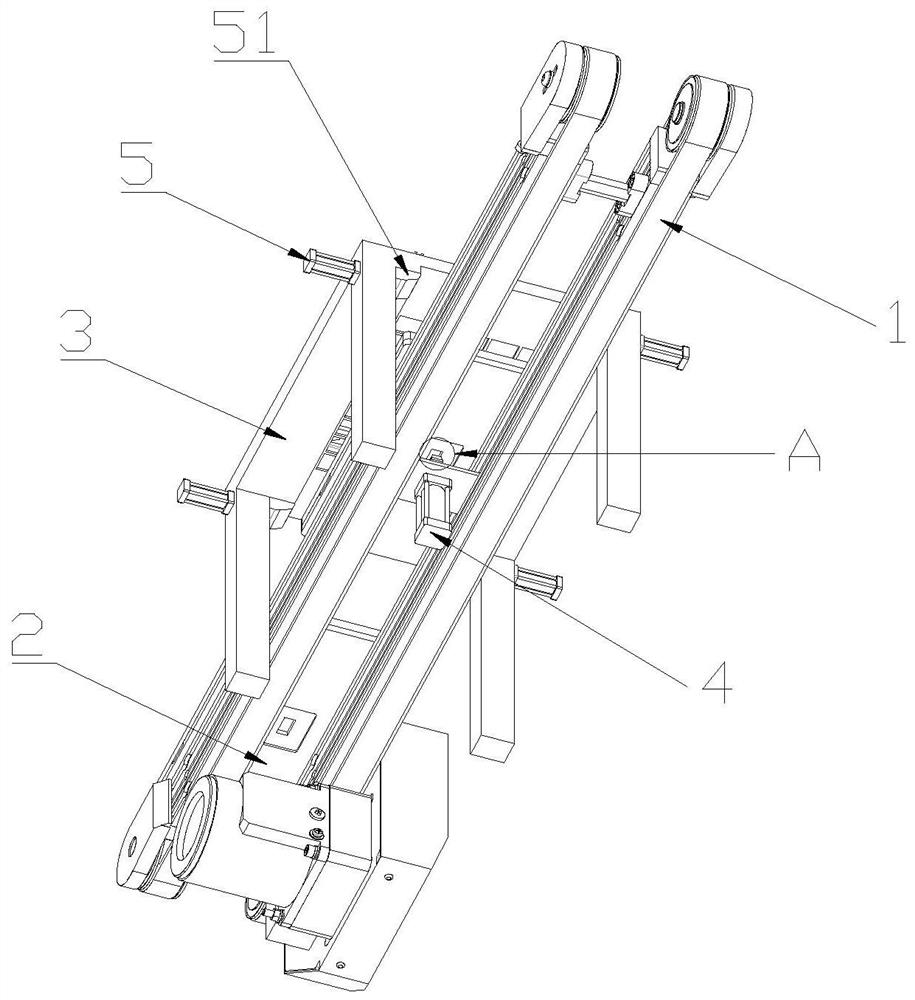

[0056] A forming device for the production of decorative wall panels, the forming device includes a conveying part 1, and two sets of supporting parts 2 are arranged on the conveying part 1, such as figure 1 , figure 2 , image 3 As shown, the supporting member 2 includes a forming support plate 22, the conveying member 1 is provided with a first supporting frame 3, the first supporting frame 3 includes a forming frame 34, the conveying member 1 is provided with a driving member 4, and the first supporting frame 3 There is a locking part 5 on it, and the driving part 4 lifts the forming support plate 22 to the bottom of the forming frame body 34 , and the forming supporting plate 22 is locked and fixed by the locking part 5 .

[0057] The first support frame 3 is provided with a cloth part 10, a vibrating part 8 and a spraying part 9. The cloth part 10 evenly distributes the material in the forming frame 34, and the vibrating part 8 is used for vibration molding, and the loc...

Embodiment 2

[0077] On the basis of Embodiment 1, a sprayer 9 is provided, and the sprayer 9 is located on the second support frame 7. After the veneer wallboard is demoulded, grease is sprayed onto the forming frame 34 through the sprayer 9 to facilitate the demoulding of the wallboard.

[0078] The sprinkler 9 specifically includes a vertical high-pressure pipe 91 fixed in the second through hole 73, such as Figure 14 As shown, a horizontal high-pressure pipe 92 placed horizontally is provided below the vertical high-pressure pipe 91, a connecting pipe 93 is provided below the horizontal high-pressure pipe 92, and a nozzle 94 is provided below the connecting pipe 93.

[0079] The fats and oils described in this embodiment are vegetable fats and oils such as soybean oil and peanut oil.

[0080] A method for producing a decorative wallboard, the production method comprising the following steps:

[0081] S1: Fabric

[0082] Put the material in the hopper 101, while the material distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com