Prefabricated concrete laminated slab hoisting device

A prefabricated concrete and hoisting device technology, applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of time-consuming, low accuracy, time-consuming and labor-intensive calibration process, achieve high accuracy, increase applicability, and improve practicality sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in the embodiments of the present invention; obviously, the described embodiments are only some embodiments of the present invention; rather than all embodiments. Based on the embodiments of the present invention; all other embodiments obtained by persons of ordinary skill in the art without creative work; all belong to the protection scope of the present invention.

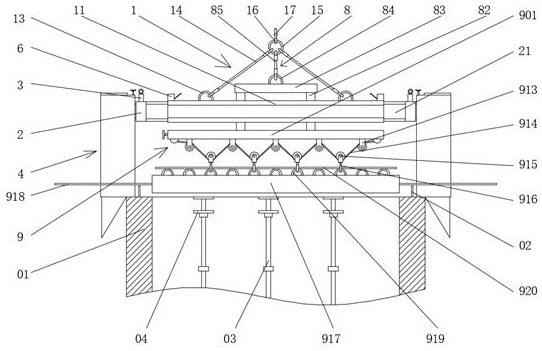

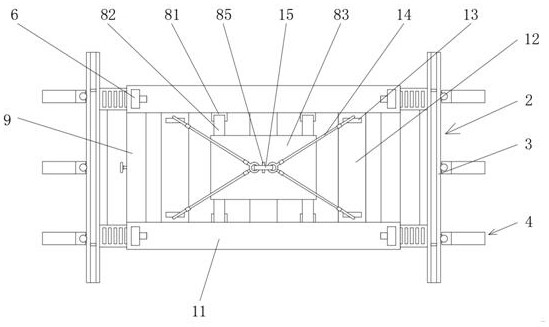

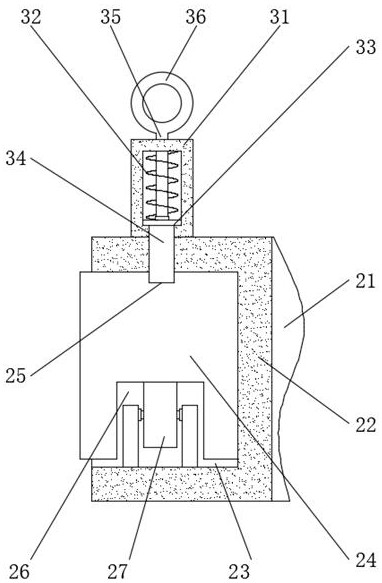

[0031] see Figure 1-8 , a prefabricated concrete composite panel hoisting device, including a hoisting device 1, the hoisting device 1 includes an I-shaped lifting edge bar 11, the number of the I-shaped lifting edge bar 11 is two, and the two I-shaped lifting edge bars 11 are arranged in parallel, two Three I-shaped reinforcements 12 are fixedly connected between the two I-shaped lifting side bars 11, and the top surfaces of the two I-shaped rein...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com