Hidden-screen colorful touch film and production process thereof

A production process and touch film technology, applied in printing processes, instruments, coatings, etc., can solve problems such as insufficient ink adhesion, and achieve the effects of increasing ink adhesion, facilitating maintenance, and improving position accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

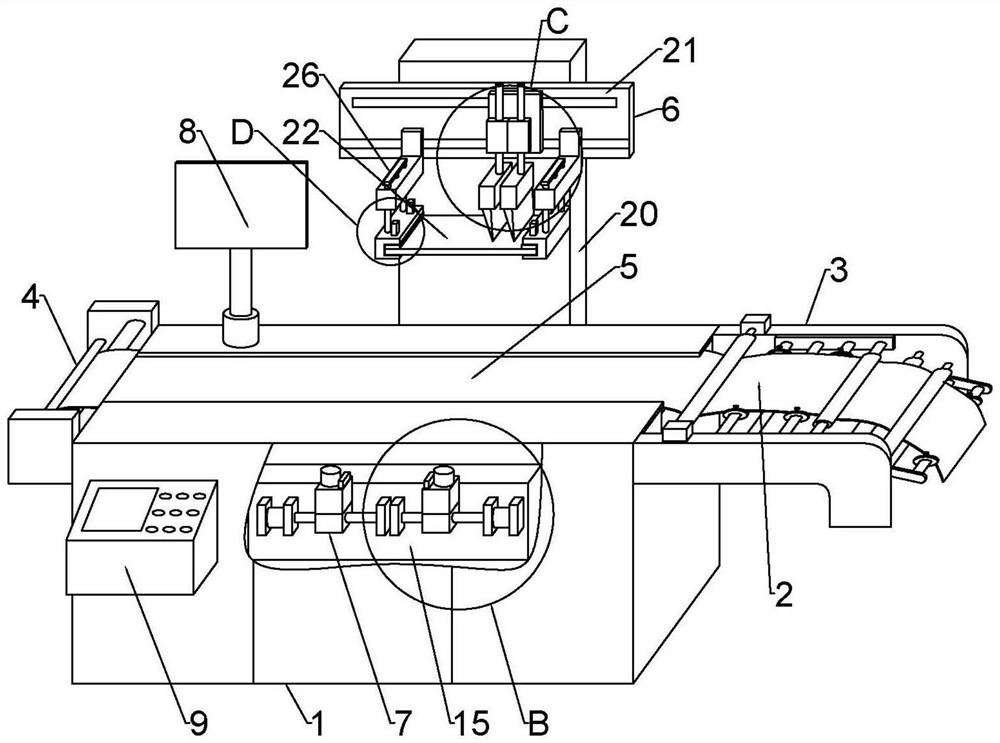

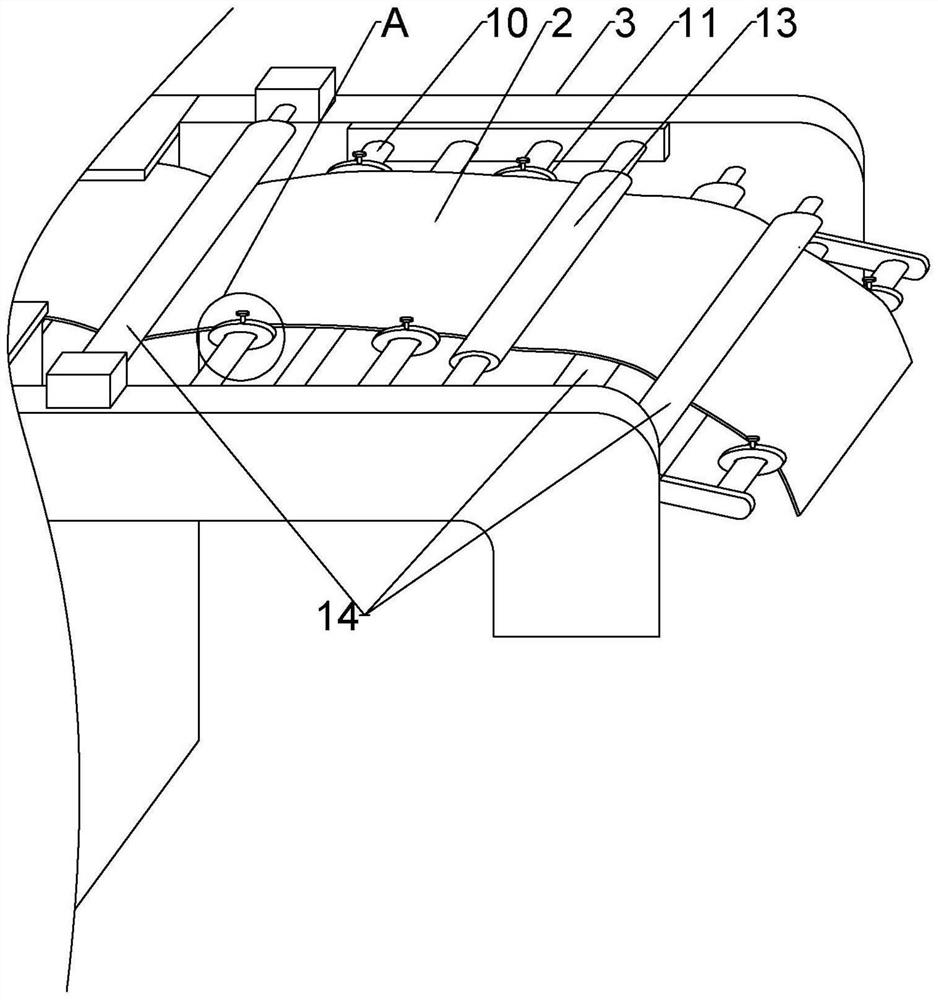

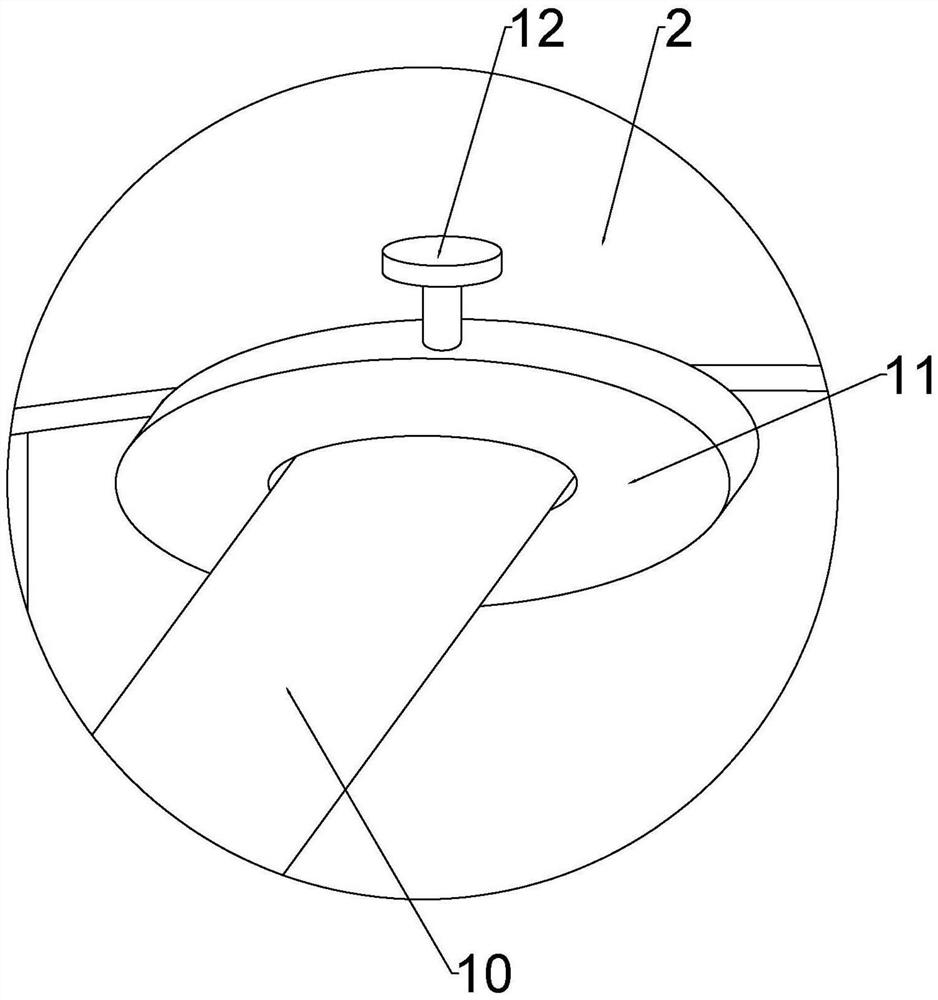

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0036] A kind of hidden screen dazzling touch film, it comprises base film 2, and the thickness of base film 2 is 0.125mm~0.3mm, and the surface of base film 2 is covered with transparent coating, and the thickness of transparent coating is 0.020mm~0.005mm, the transparent coating includes the following raw materials by weight percentage: acrylic resin 8%~12%, polyester acrylic resin 22.5%~27%, ethyl acetate 40%~45%, propylene glycol methyl ether 6.5%~ 10%, 8.5% to 11.5% isopropanol and 3.8% to 7% unsaturated polyester resin, the base film 2 is fixedly connected with the transparent coating through high temperature baking treatment and preheating shrinkage treatment respectively. The thickness of the base film 2 is 0.15 mm. The thickness of the transparent coating is 0.015mm-0.007mm.

[0037] By weight percentage, the transparent coating comp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com