Assembled high load-bearing periodic porous structure

A porous structure, periodic technology, applied in the direction of building elements, sheets/plates, etc., can solve the problems of complex topology configuration of periodic porous structures, limited preparation size of periodic porous structures, and high manufacturing costs of periodic porous structures , to achieve the effect of low relative density, good scalability and expansibility, and meet the needs of structural bearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

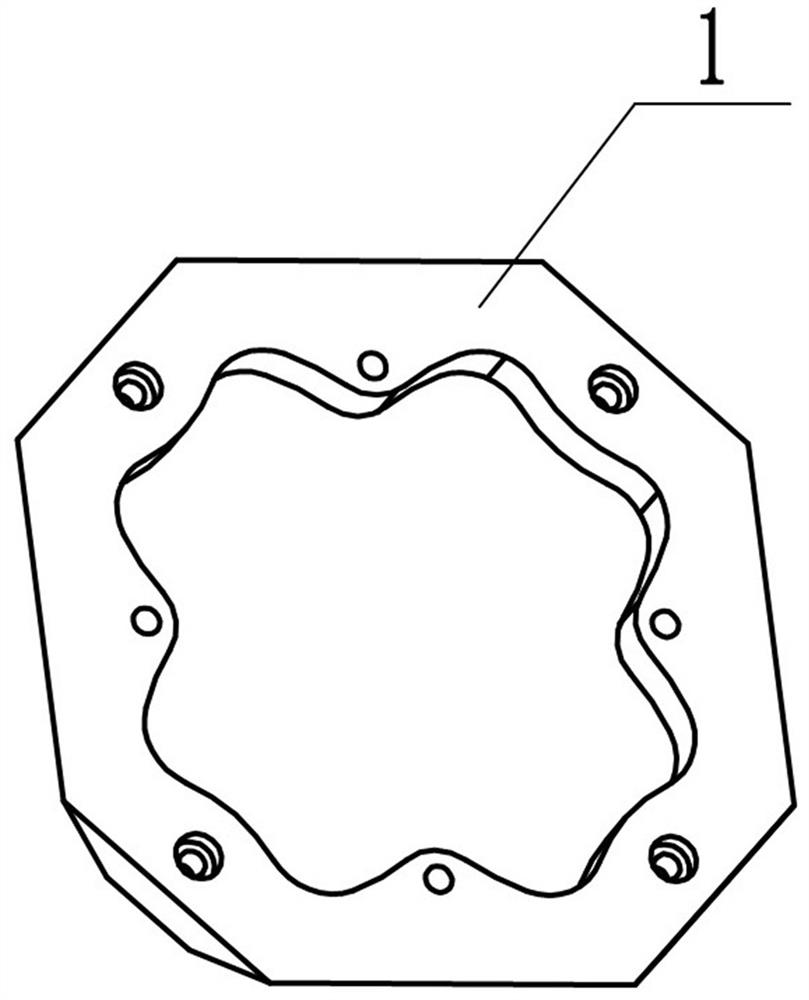

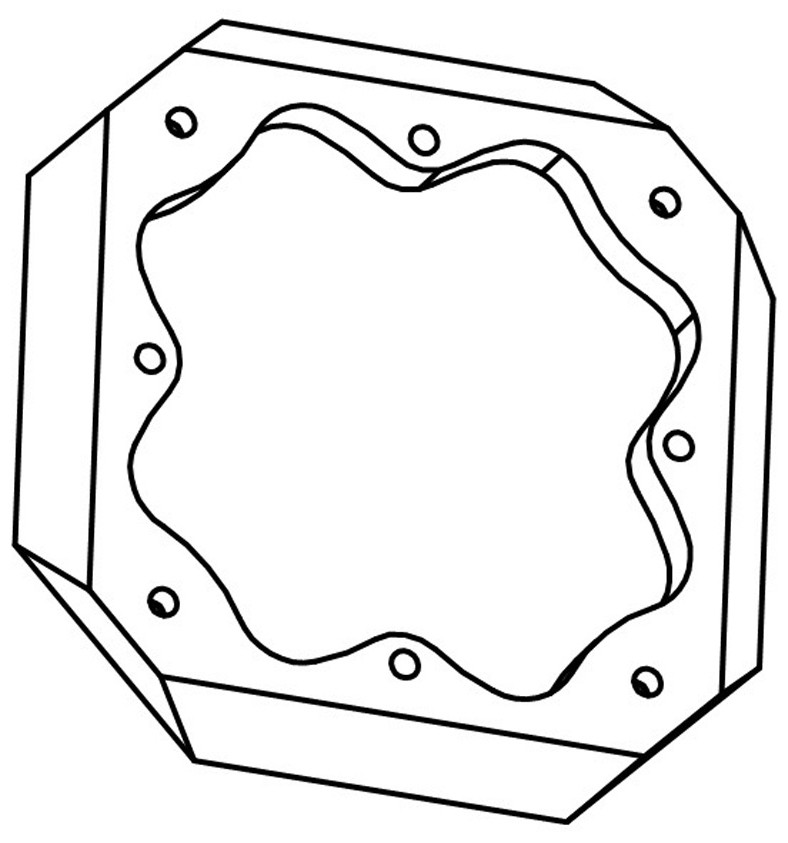

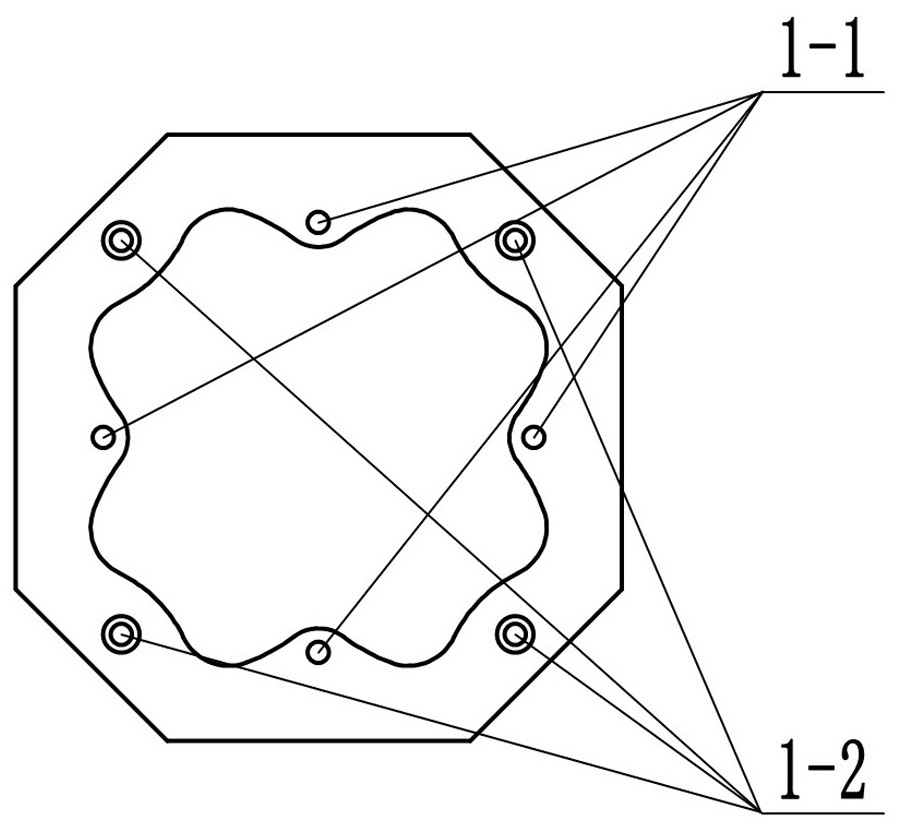

[0039] see Figure 1-11 , The assembled high-load-bearing periodic porous structure provided by the present invention is composed of a certain number of ring blocks 1, corner codes 2 and bolt groups.

[0040] Further, the outer side of the ring block is octagonal, and the inner side is a closed and symmetrical curve with a certain thickness; the ring block is designed with 2 sets of mounting holes, the first set of mounting holes is 4 through holes, which are set at the same x , y At the midpoint of the side parallel to the axis, the second set of mounting holes 1 is 4 stepped holes, which are set on x , y The axis is on the side of ±45°; the ring block and x , y The sides of the sides parallel to the axis are designed as 45° bevels, which are compatible withx , y The side of the side with the axis at ±45° is designed as a 90° plane; the ring block is in contact with the x The axes are symmetric about the center in the orientations of 0°, 45°, 90° and 135°.

[0041] Fur...

Embodiment 2

[0049] see Figure 12-14 , in order to improve the connection strength of the periodic porous structure, the connection mode between the porous unit cells can be adjusted.

[0050] Specifically, as described in Example 1, when the first porous unit cell 4 and the second porous unit cell 5 are connected, on the coincident surface, the first porous unit cell fastens the bolt The axes of group 4-1 and the second porous unit cell fastening bolt group 5-1 are coincident, and they are two independent sets of bolt groups.

[0051] Further, the four sets of the first porous unit cell fastening bolt group 4-1 and the second porous unit cell fastening bolt group 5-1 on the overlapping surface are removed, and the third bolt group 7 is used for mechanical connection , the third bolt group 7 directly fastens the first porous unit cell 4 and the second porous unit cell 5, which helps to improve the strength and stability of the porous structure.

Embodiment 3

[0053] see Figure 15-17 , the assembled high-load periodic porous structure provided by the present invention can realize the connection of multi-unit large-scale periodic porous structures.

[0054] Specifically, when the first porous unit cell 4, the second porous unit cell 5, the third porous unit cell 9 and the fourth porous unit cell 10 are assembled, first perform 2 according to embodiment 1 or embodiment 2. assembly of unit cells.

[0055] Further, the first porous unit cell 4, the second porous unit cell 5, the third porous unit cell 9 and the fourth porous unit cell 10 will form a cross-shaped porous structure around an overlapping edge, and the overlapping Four fourth bolt groups 8 need to be installed around the edge, and the fourth bolt group 8 sequentially controls the first porous unit cell 4, the second porous unit cell 5, and the third porous unit cell in a clockwise or counterclockwise order. The unit cell 9 and the fourth porous unit cell 10 are fastened. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com