Automatic batching process

An automatic batching and process technology, applied in the direction of crucible furnace, furnace, lighting and heating equipment, etc., can solve the problems of increasing labor consumption and wasting manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

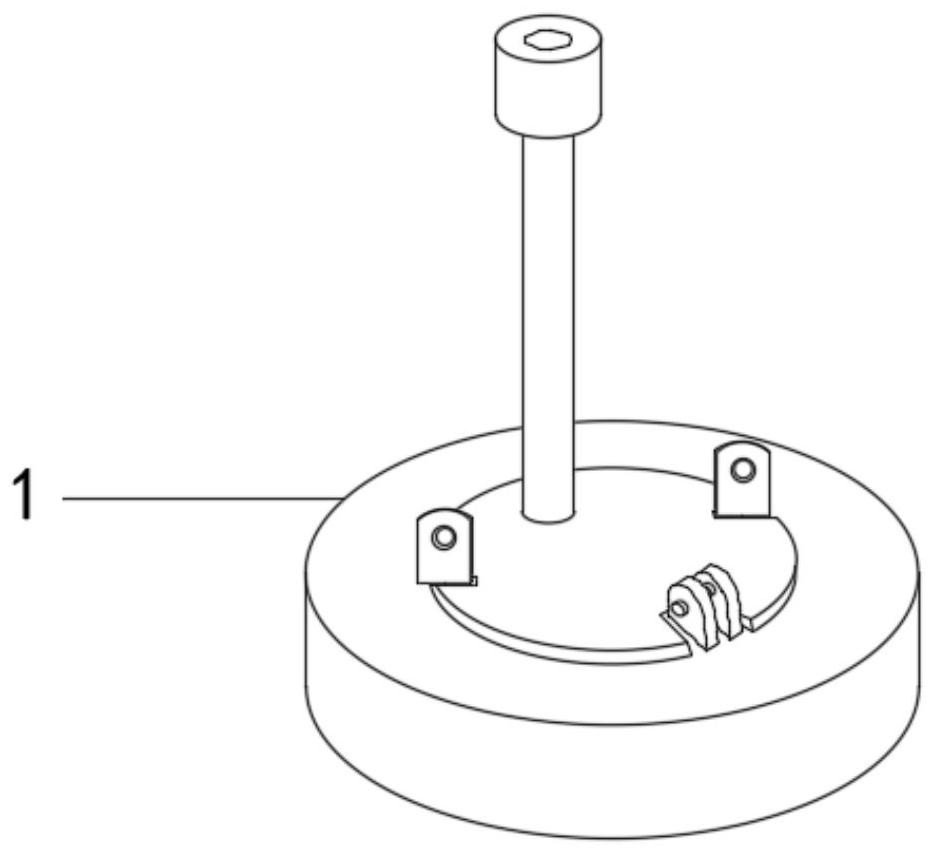

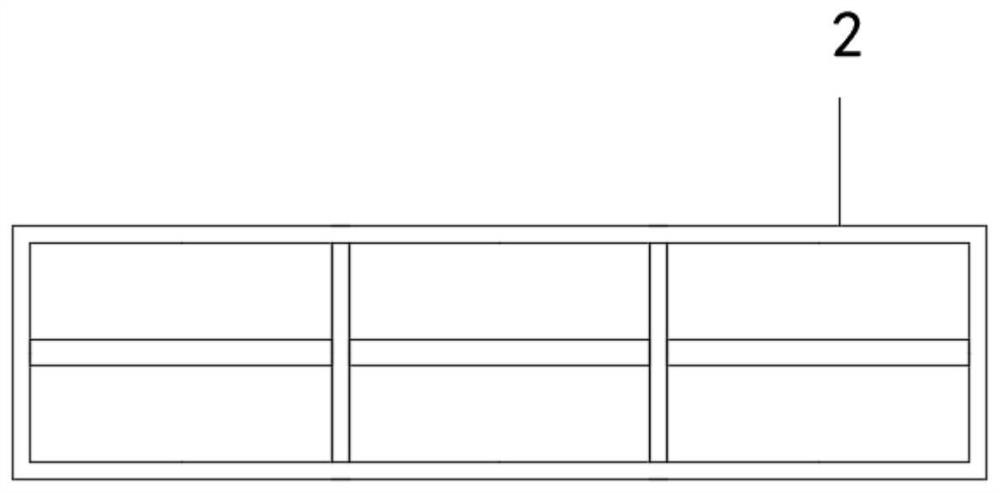

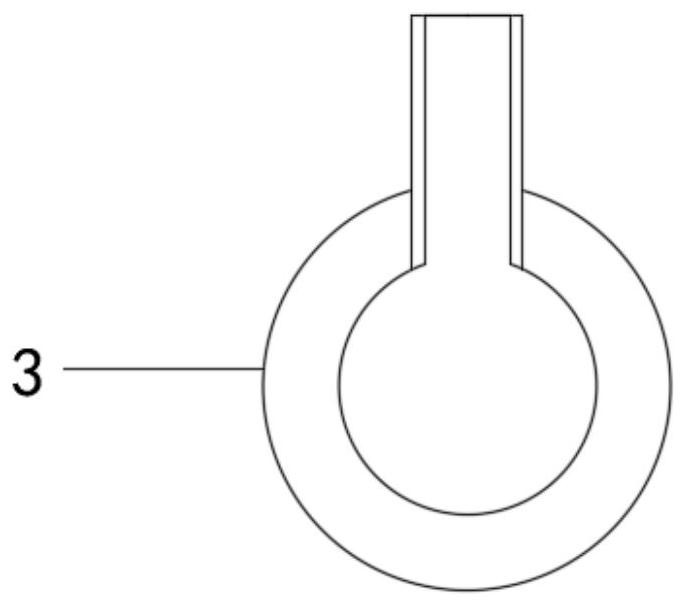

[0026] Refer to attached Figure 1-Figure 5 , automatic batching process, including electromagnetic chuck 1, pit 2, electric furnace mouth 3 and vibrating feeding car 4;

[0027] Further, the specific process flow is as follows:

[0028] S1: There is a pit 2 at the material distribution end, and metal element materials are stored inside the pit 2. The metal element materials are manganese, picks and various metal element materials. There are multiple pits 2, and in each pit A kind of metal element material is stored. The pit 2 is only constructed of cement bricks. The depth of the pit 2 is 1.5 meters to 2 meters. The length and width of the pit 2 are both 2 meters....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com