Current sensor and current sensor module

A current sensor and core technology, applied in the direction of measuring current/voltage, voltage/current isolation, instruments, etc., can solve the problems of miniaturization and unfavorable sensor size, reduce influence, suppress excessive flux leakage, and increase magnetoresistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

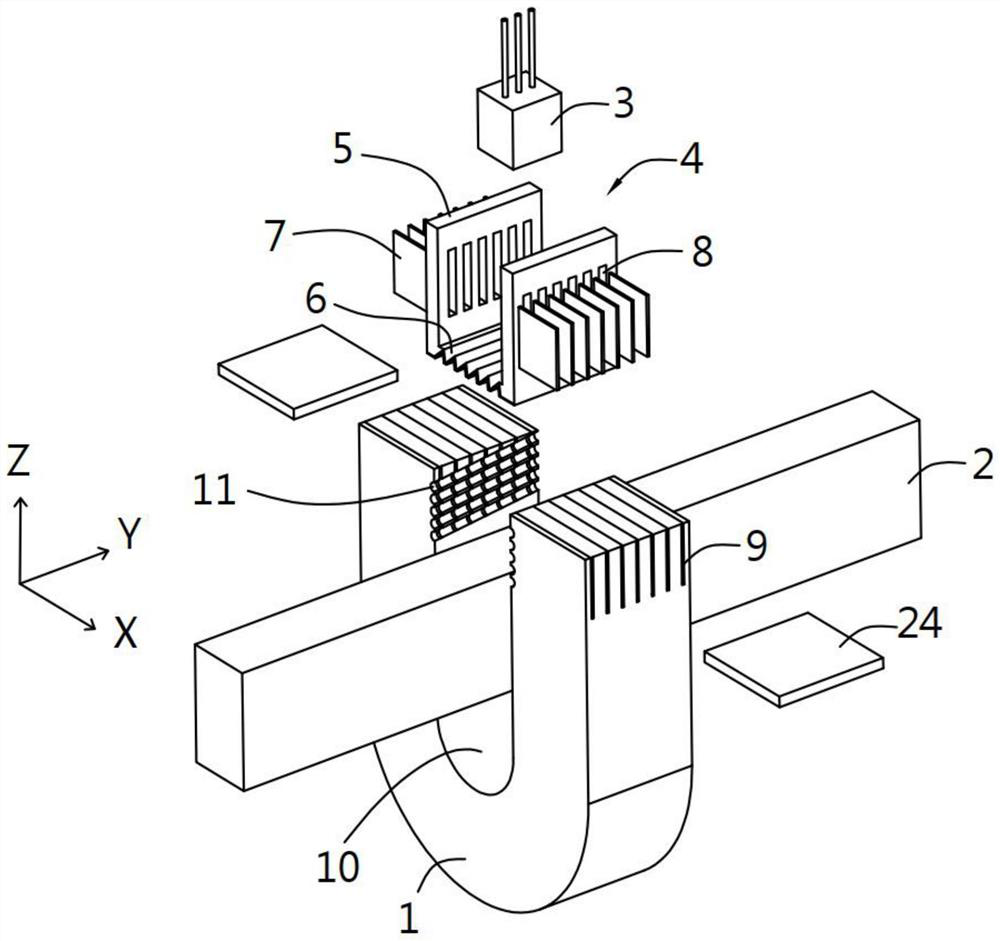

[0036] see Figure 1 to Figure 5 , the present invention provides a kind of technical scheme:

[0037] A current sensor, the sensor is mainly composed of the following components:

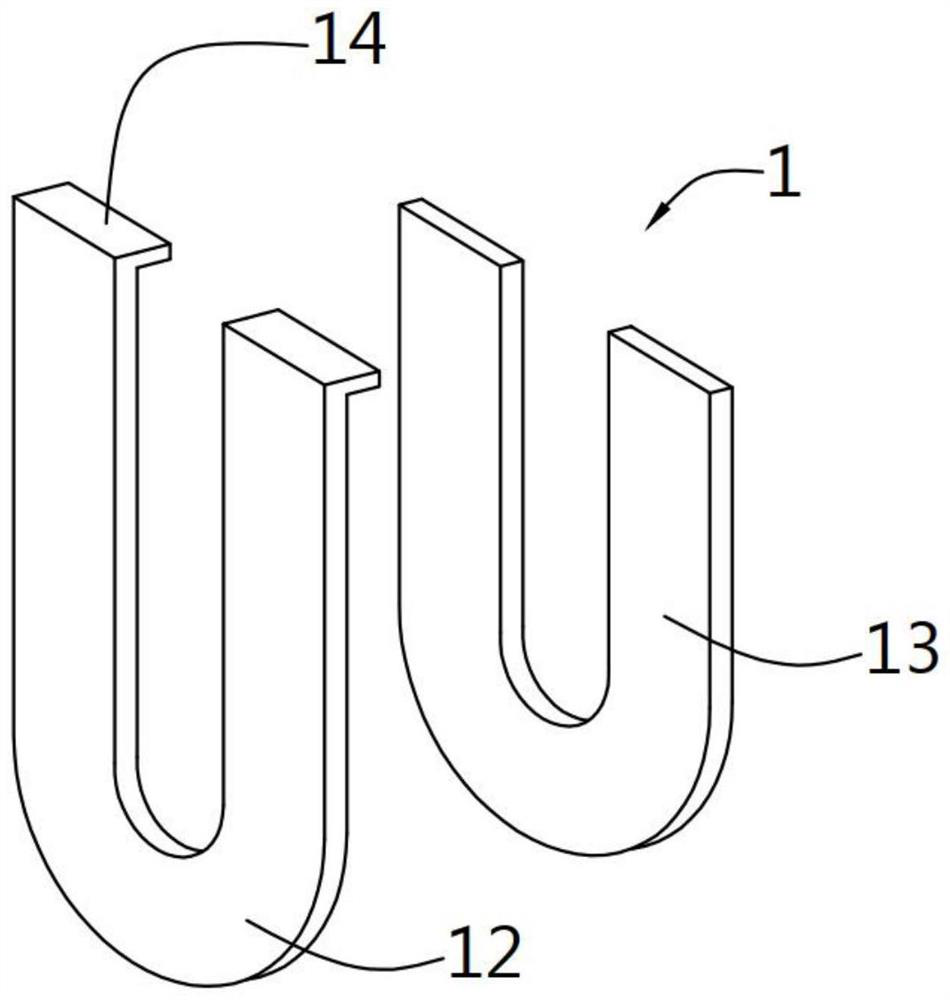

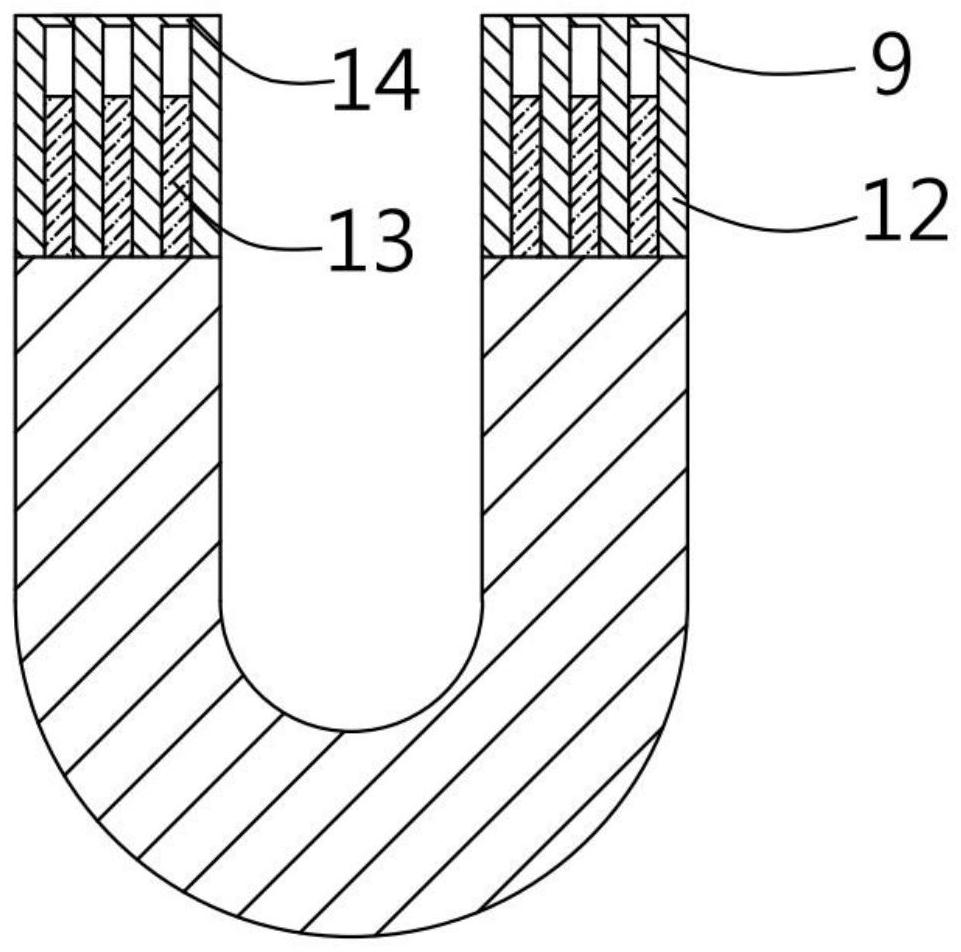

[0038] The core part 1 is mainly a U-shaped plate with a U-shaped groove 10 formed by stacking a plurality of first core parts 12 and second core parts 13 together;

[0039] The loop conductor 2 is inserted on the inner side of the U-shaped slot 10 of the above-mentioned core 1, and is used for the current to be measured to flow;

[0040] The resting portion 4 is arranged on the open side of the upper end of the aforementioned U-shaped groove 10;

[0041] The detection unit 3, installed in the aforementioned resting part 4, is used to detect the strength of the magnetic field;

[0042] a housing 20 for supporting the core 1, the loop conductor 2 and the detection unit 3;

[0043] A channel structure for supporting the resting portion 4 is formed on the upper end of the above-mentioned core port...

Embodiment 2

[0052] see Figure 6 to Figure 7 , the present invention provides a kind of technical scheme:

[0053] The structure of the second embodiment is basically the same as that of the first embodiment, the difference is that the channel structure includes the first core 12 or the second core located on the outermost side when the first core 12 and the second core 13 are stacked. The upper end of the part 13 has a resilient part 15, and the end of the core 1 except the first core part 12 or the second core part 13 located at the outermost side is a flush end 19, and the resilient part 15 is flush with the flush end 19. A region 18 for suppressing an increase in hysteresis loss is formed therebetween. The above-mentioned resting part 4 includes a springback distance 27 between the two springable parts 15 , and the detection unit 3 is stuck in the springback distance 27 . The aforementioned resilient portion 15 includes a straight portion 16 and an elastic curved portion 17. One end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com