Aluminum substrate, method for manufacturing same and LED light source with aluminum substrate

A manufacturing method and aluminum substrate technology, which is applied in the direction of multilayer circuit manufacturing, printed circuits connected with non-printed electrical components, electrical components, etc., can solve the problem of the difficulty in precisely controlling the heat conduction insulation layer, the reduction of heat conduction and heat dissipation effects, and the problems of heat conduction and insulation. Low layer reflectivity and other issues, to save semiconductor materials, improve production efficiency, and facilitate miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

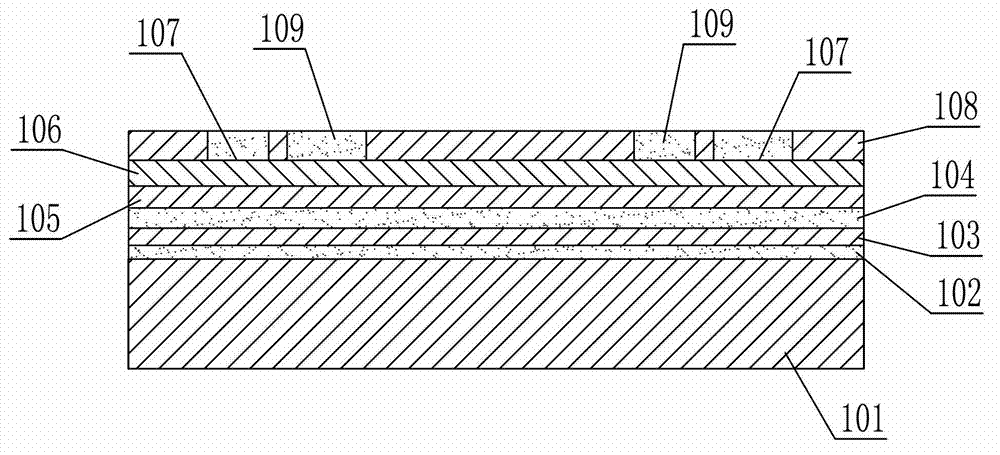

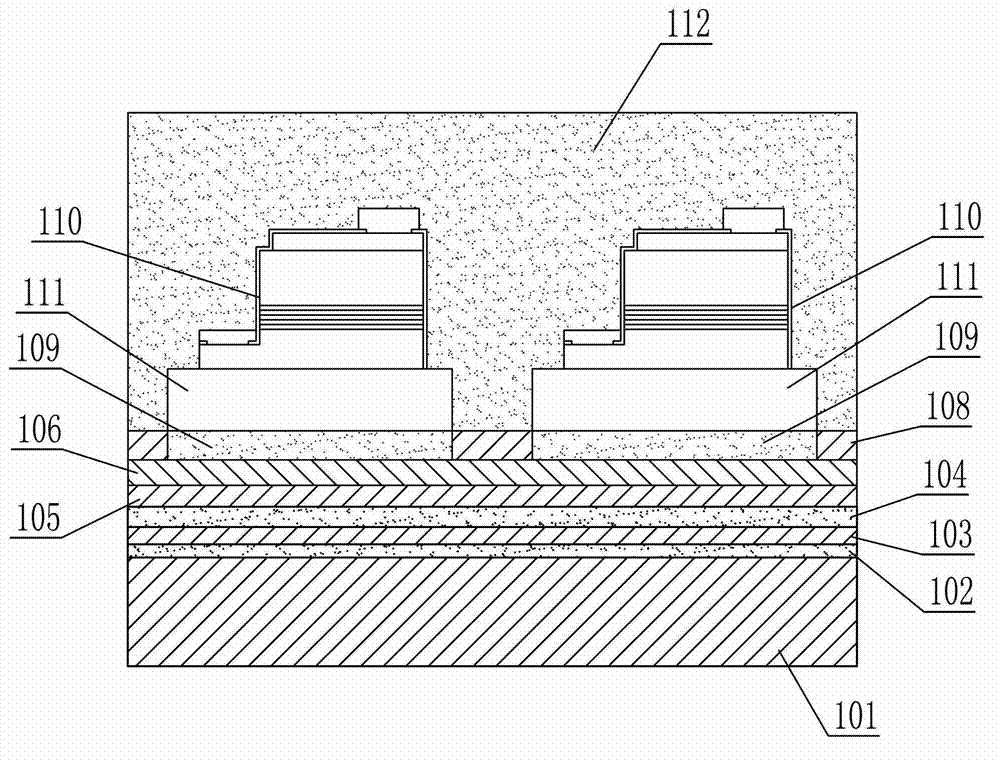

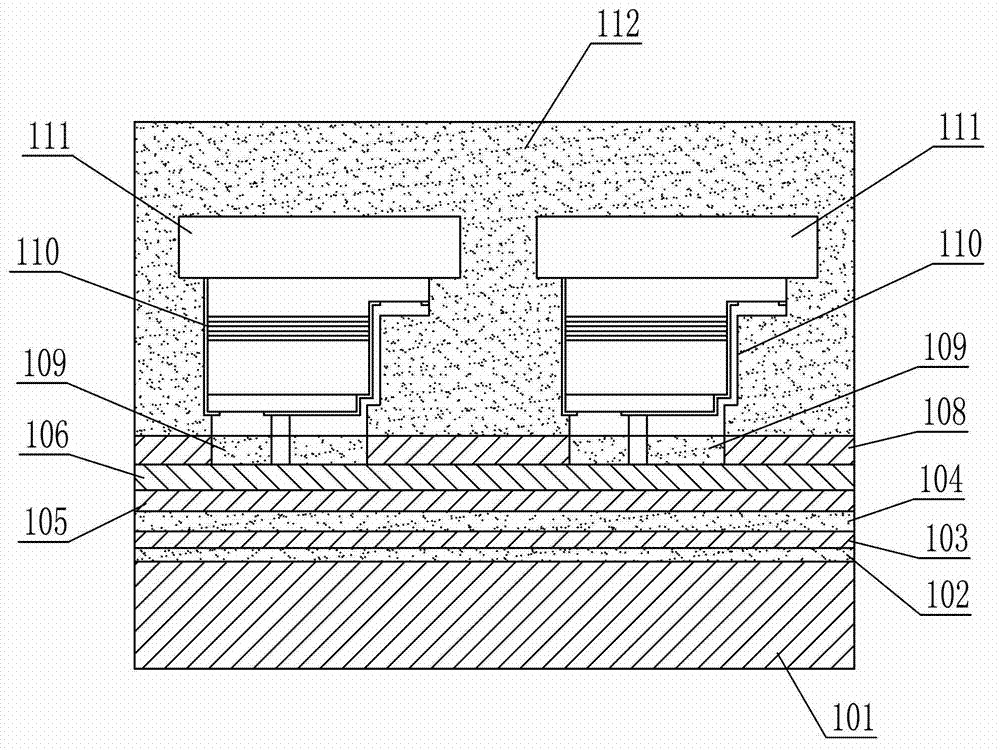

[0035] see figure 1 , the aluminum substrate shown in the figure includes an aluminum base plate 101, and the surface of the aluminum base plate 101 is sequentially provided with a conductive metal layer, a transparent metal oxide insulating layer 103, and a metal thin film layer 102; the conductive metal layer includes the first A conductive metal layer 105 and a second conductive metal layer 106 covering the first conductive metal layer 105, the second conductive metal layer 106 is provided with a conductive circuit (not shown) for connecting with the LED chip and fixing the LED Die-bonding functional area 107 of the chip.

[0036] Preferably, in order to prevent the first conductive metal layer 105 from peeling off from the metal oxide insulating layer 103, there is a metal buffer layer 104 on the metal oxide insulating layer 103, and the first conductive metal layer 105 is arranged on the metal buffer layer 104 on. The metal buffer layer 104 is made of tungsten, molybden...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com