Substrate integrated waveguide filter based on artificial surface plasmon

An artificial surface plasmon and filter technology, applied to waveguide devices, electrical components, circuits, etc., can solve the problem of reducing the upper sideband cut-off frequency of the filter, unfavorable filter miniaturization and integration, and filter out-of-band suppression Reduced force and other issues, to achieve the effect of improved selectivity, good out-of-band suppression ability, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

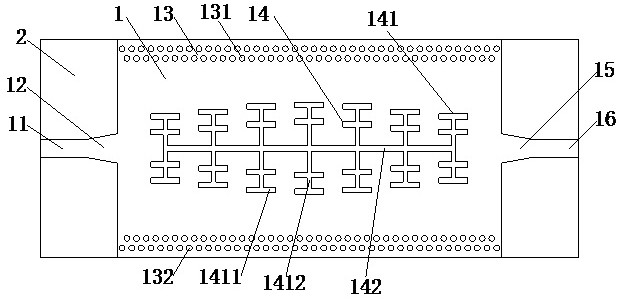

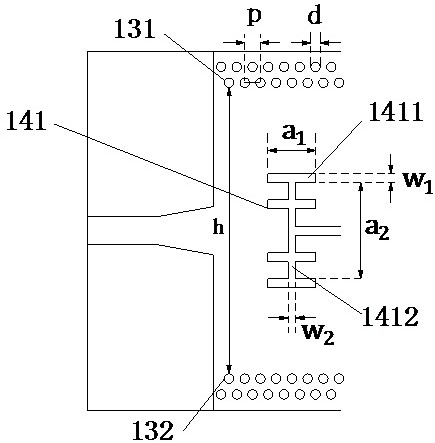

[0031] like figure 1 and figure 2 Shown: a substrate-integrated waveguide filter based on artificial surface plasmons, including a dielectric substrate 2, an upper circuit board 1 located on the upper surface of the dielectric substrate 2 and a lower ground plate 3 located on the lower surface of the dielectric substrate 2, the upper layer The circuit board 1 includes an input port 11 , an ML-SIW transition portion 12 , a substrate integrated waveguide portion 13 , an SIW-ML transition portion 15 and an output port 16 . The English of the microstrip line is Microstrip Line (ML), the English of the substrate integrated waveguide is Substrate integrated waveguide (SIW), the ML-SIW transition part 12 is the microstrip line-substrate integrated waveguide transition part, and the SIW-ML transition part 15 Then it is the substrate integrated waveguide-microstrip line transition part, the input port 11, the output port 16, the ML-SIW transition part, and the SIW-ML transition part ...

Embodiment 2

[0037] like figure 1 and image 3 As shown, this embodiment discloses a substrate-integrated waveguide filter based on artificial surface plasmons, and the lower sideband cut-off frequency f of the filter is d It can be adjusted through the metal via hole array structure of the substrate integrated waveguide part 13 . Specifically, the distance between the upper metal via array 131 and the lower metal via array 132 is h, and the lower sideband cut-off frequency of the filter is f d , both satisfy:

[0038]

[0039] In the formula, c is the speed of light in vacuum, and ε is the relative permittivity of the dielectric substrate. From the above formula, it can be obtained that the value of h increases, and the lower sideband cut-off frequency f d Decrease, the h value decreases, then the lower sideband cut-off frequency f d increase. Therefore, adjusting the distance between the upper metal via array 131 and the lower metal via array 132 can change the lower sideband cut...

Embodiment 3

[0045] like figure 1 and Figure 4 As shown, this embodiment discloses a substrate-integrated waveguide filter based on artificial surface plasmons, the artificial surface plasmon structure 14 includes N artificial surface plasmon units 141, and the range of N is , 2≤N≤11. As preferred, the value of N is 7, figure 1 The shown filter adopts 7 artificial surface plasmon units 141, and its upper sideband cutoff frequency is as Figure 4 Shown at 7GHz, the lower sideband cutoff frequency is 5GHz, and the filter bandwidth is 2GHz.

[0046] According to the filtering performance requirements of the filter, the artificial surface plasmon structure can be designed as 2 to 11 artificial surface plasmon units. Generally speaking, the higher the operating frequency of the filter, the artificial surface plasmon The less the number of units, at least 2 can be designed. Limited by the working mechanism of the device, the upper sideband cut-off frequency of the traditional substrate-int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com