Wide-temperature nanoparticle counter

A nanoparticle and counter technology, applied in individual particle analysis, particle and sedimentation analysis, instruments, etc., can solve the problems that cannot meet the needs of wide temperature nanoparticle measurement, and achieve the effect of accurate counting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

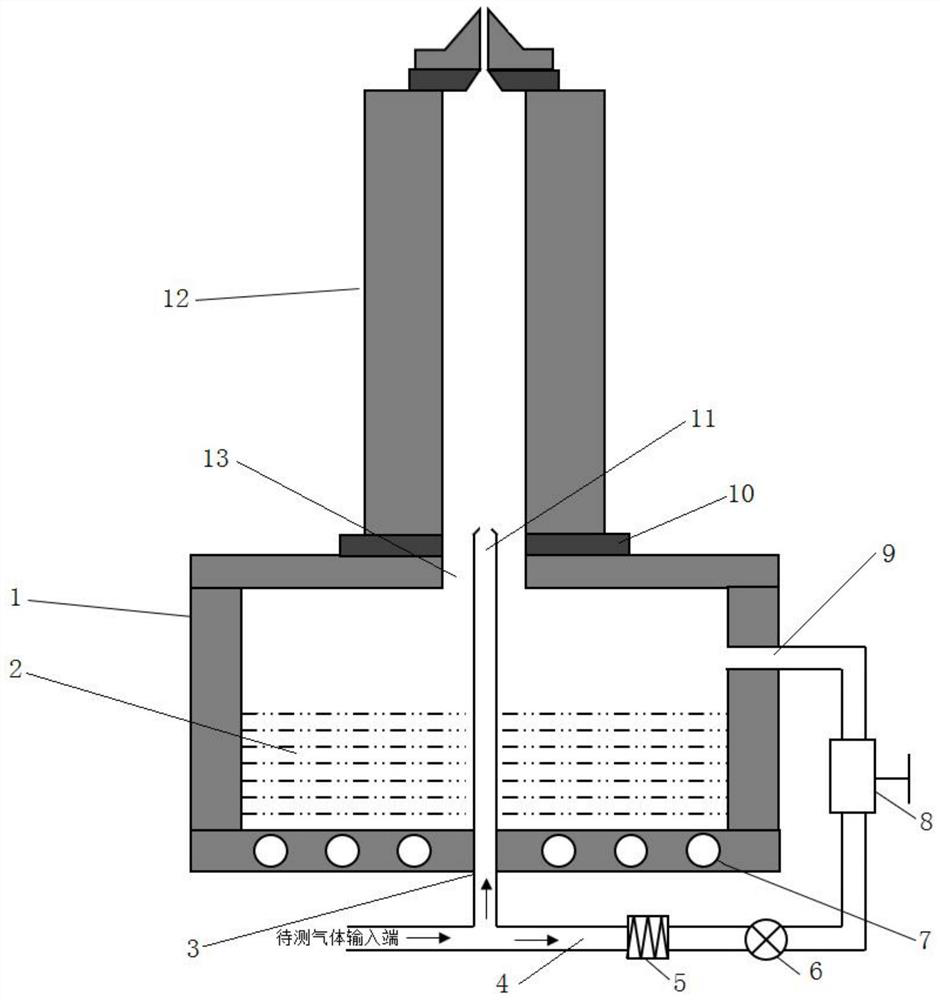

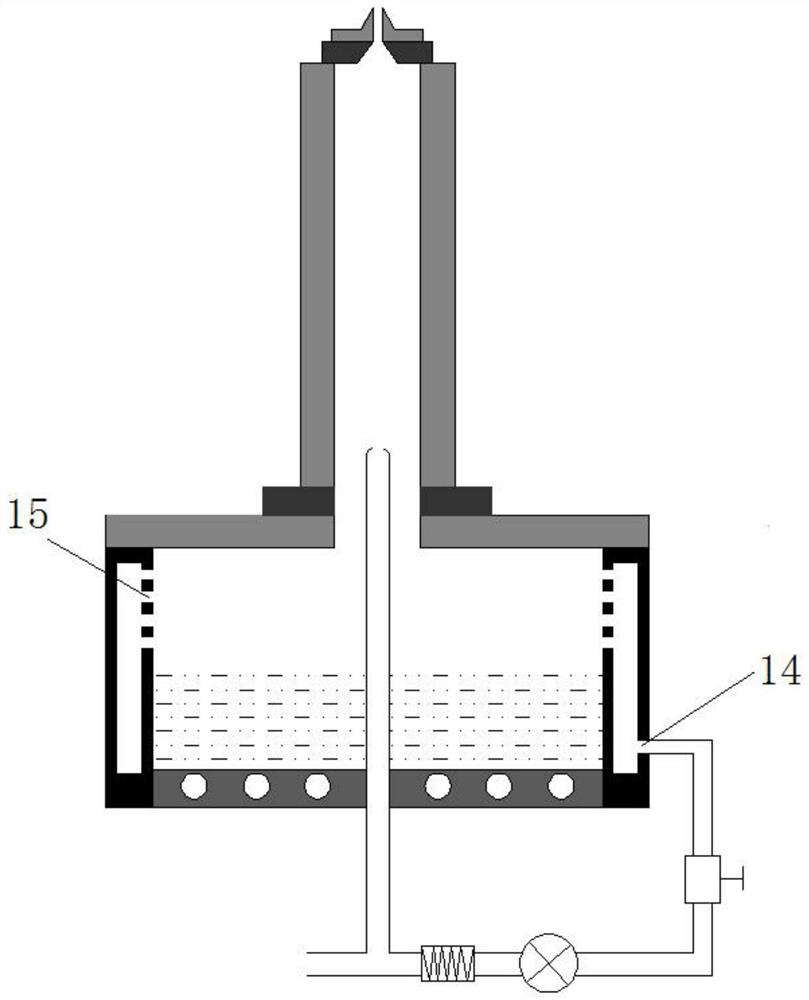

[0044] see figure 1 , the present embodiment provides a kind of wide-temperature nanoparticle counter, this wide-temperature nanoparticle counter comprises: intake shunt structure, saturator, condenser 12 and optical counter, saturator is connected with condenser 12, and condenser 12 is connected with The optical counters are connected, and the saturator, the condenser 12 and the optical counter are all provided with a temperature control unit for adjusting and controlling the temperature of the saturator, the condenser 12 and the optical counter. The temperature of the saturator is higher than the temperature of the condenser, and the liquid working medium whose thermal diffusivity is greater than the mass diffusivity is stored in the saturator. The gas to be tested is divided into two paths after it enters the input port of the gas to be tested. One path enters the pretreatment pipeline 4 for filtration and then enters the saturator, and carries the working medium vapor in t...

Embodiment 2

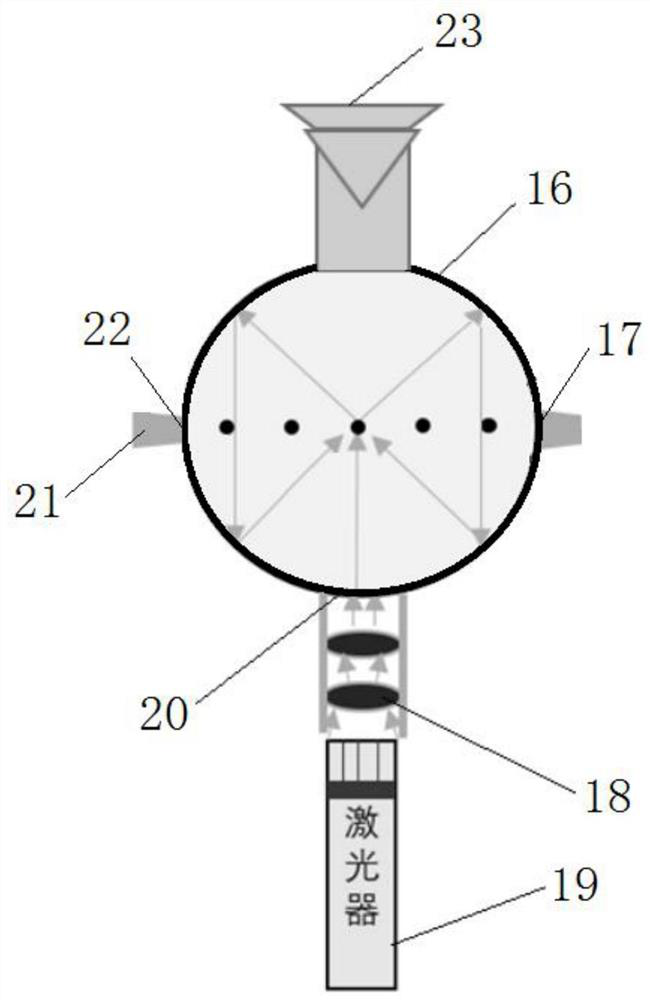

[0066] Such as image 3 As shown, the optical particle counter includes: a scattered light collection device, an aerosol particle collimation structure and a laser. Among them, see image 3 , in this embodiment, the scattered light collecting device is preferably an integrating sphere 16 . The integrating sphere 16 is provided with an aerosol particle inlet 22 , an aerosol particle outlet 17 and a laser irradiation inlet 20 . The aerosol particle collimating structure is used to linearly transport all the aerosol particles entering the integrating sphere 16 from the aerosol particle inlet 22 to the aerosol particle outlet 17 and discharge them from the aerosol particle outlet 17 . In order to avoid the phenomenon that many aerosol particles remain in the integrating sphere 16 and cannot be discharged. The laser light emitted by the laser 19 enters the integrating sphere 16 through the laser irradiation entrance 20, and the laser path intersects the movement path of the aero...

Embodiment 3

[0087] Such as Figure 14 As shown, the aerosol particle dilution system includes: a primary dilution pipeline 33 and a secondary dilution pipeline 34 . Wherein, the primary dilution pipeline 33 includes a first input pipeline 331, a second input pipeline 334 and a first gas mixing module 335, the first input pipeline 331 is connected to the gas to be detected, and the second input pipeline 334 is connected to the pure gas . Both the output end of the first input pipeline 331 and the output end of the second input pipeline 334 communicate with the input end of the first gas mixing module 335 . The secondary dilution pipeline 34 includes a first branch 341, a second branch 342 and a second gas mixing module 345, the first branch 341 is equipped with a purification filter module 343, the output end of the first branch 341 and the second The output end of the branch circuit 342 is connected to the output end of the particulate matter dilution system after converging at the seco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com