Equipment management method and device, electronic equipment and storage medium

A device management and equipment technology, applied in data processing applications, electrical digital data processing, special data processing applications, etc., can solve problems such as low work efficiency and poor accuracy, and achieve the effect of improving work efficiency and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

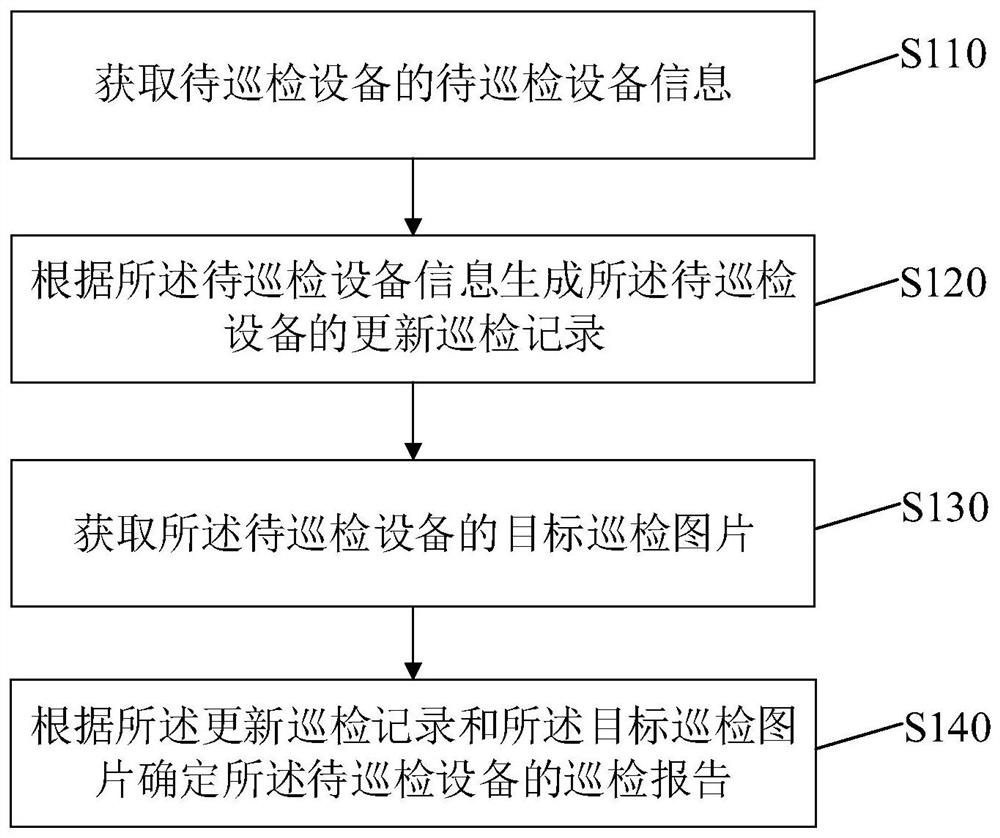

[0028] figure 1 It is a flow chart of an equipment management method provided by Embodiment 1 of the present invention. This embodiment is suitable for recording the inspection information of the equipment to be inspected in real time. The method can be executed by an equipment management device, and the device can use software and It may be implemented in a hardware manner, and may generally be directly integrated into an electronic device that executes the method. Such as figure 1 As shown, the device management method may include the following steps:

[0029] S110. Obtain the information of the equipment to be inspected of the equipment to be inspected.

[0030] Among them, the equipment to be inspected can be any equipment that needs to be inspected, for example, it can include the electromechanical equipment to be inspected that needs to be inspected in the production workshop, and can also include the power distribution network to be inspected that needs to be inspecte...

Embodiment 2

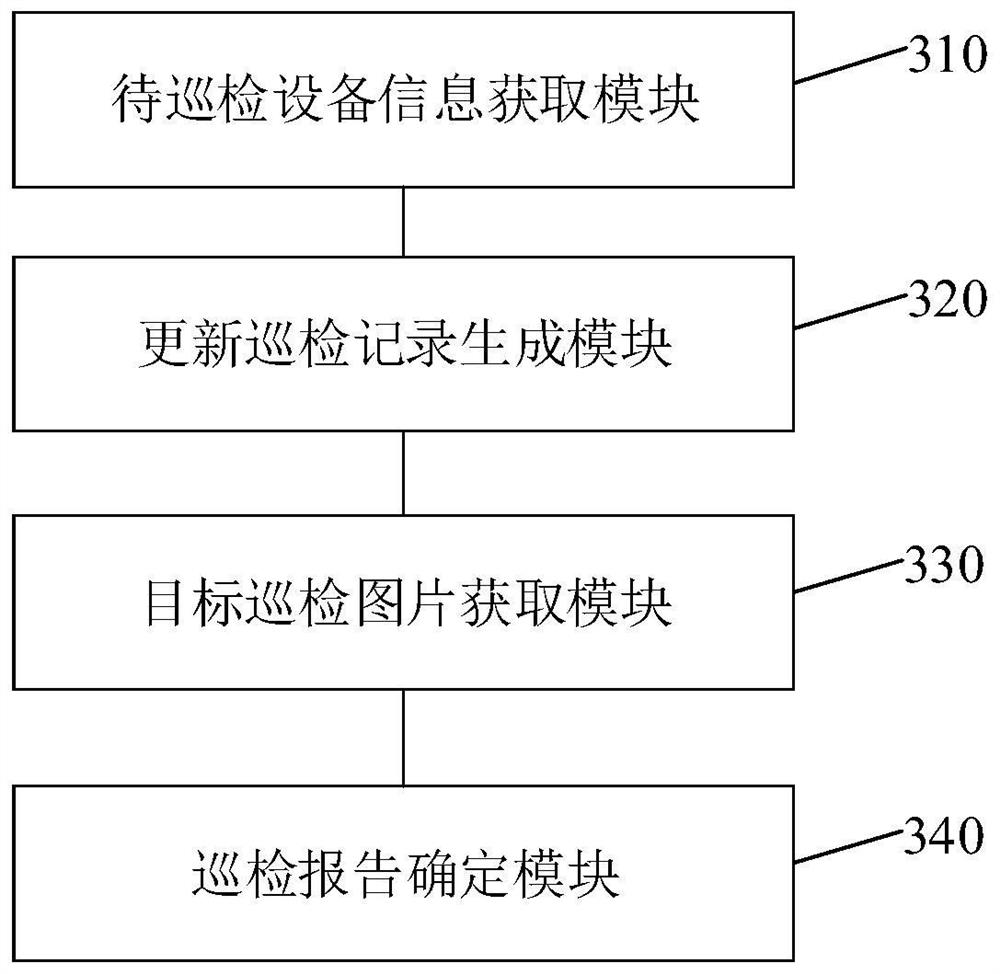

[0063] image 3 It is a schematic diagram of an equipment management device provided in Embodiment 2 of the present invention, such as image 3 As shown, the device includes: an information acquisition module 310 of equipment to be inspected, an updated inspection record generation module 320, a target inspection image acquisition module 330, and an inspection report determination module 340, wherein:

[0064] The information acquisition module 310 of the equipment to be inspected is used to acquire the information of the equipment to be inspected of the equipment to be inspected;

[0065] An updated inspection record generating module 320, configured to generate an updated inspection record of the device to be inspected according to the information of the device to be inspected;

[0066] A target inspection picture acquisition module 330, configured to acquire the target inspection picture of the equipment to be inspected;

[0067]An inspection report determining module 340...

Embodiment 3

[0084] Figure 4 It is a schematic structural diagram of an electronic device provided in Embodiment 3 of the present invention. Figure 4 A block diagram of an exemplary electronic device 12 suitable for use in implementing embodiments of the invention is shown. Figure 4 The electronic device 12 shown is only an example, and should not limit the functions and scope of use of the embodiments of the present invention.

[0085] Such as Figure 4 As shown, electronic device 12 takes the form of a general-purpose computing device. Components of electronic device 12 may include, but are not limited to: one or more processors 16, memory 28, bus 18 connecting various system components (including memory 28 and processor 16).

[0086] Bus 18 represents one or more of several types of bus structures, including a memory bus or memory controller, a peripheral bus, an accelerated graphics port, a processor, or a local bus using any of a variety of bus structures. For example, these ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com