Flexible circuit board

A flexible circuit board and circuit technology, applied in the direction of flexible printed circuit boards, printed circuits, printed circuits, etc., can solve the problems of high cost, inconvenient shaping and assembly, and cumbersome coating method, so as to reduce working hours and costs, The effect of easy product line assembly and easy quality control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

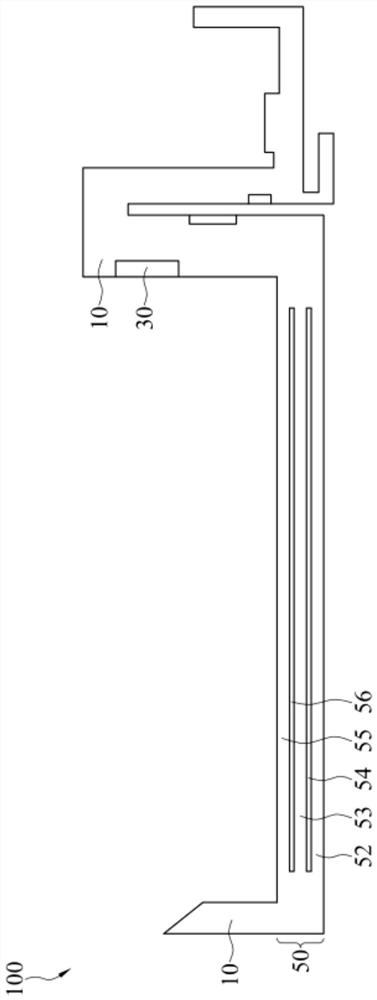

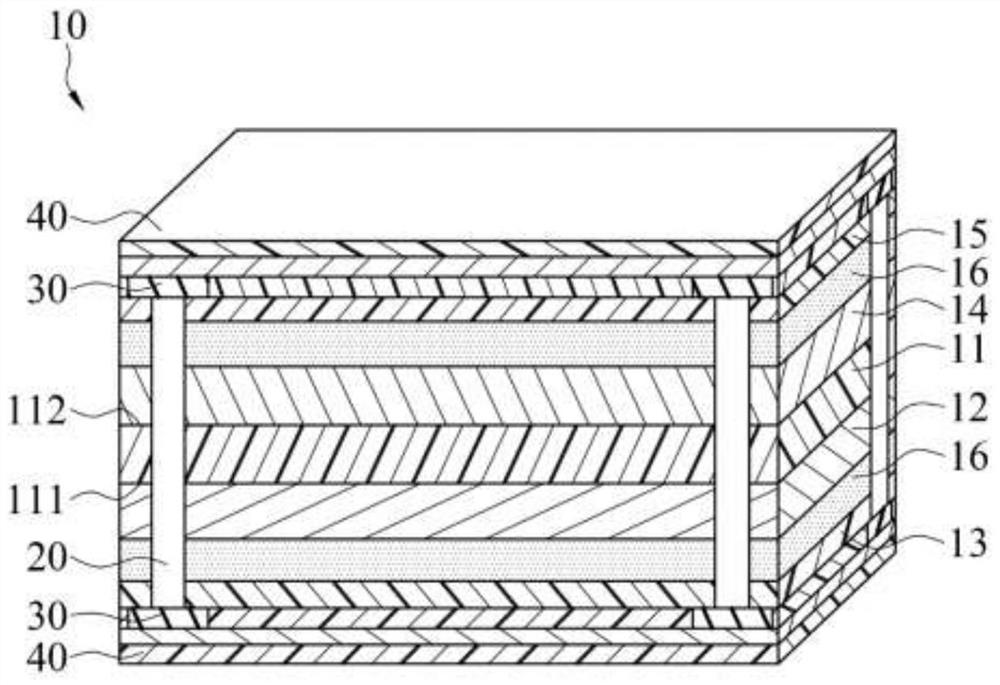

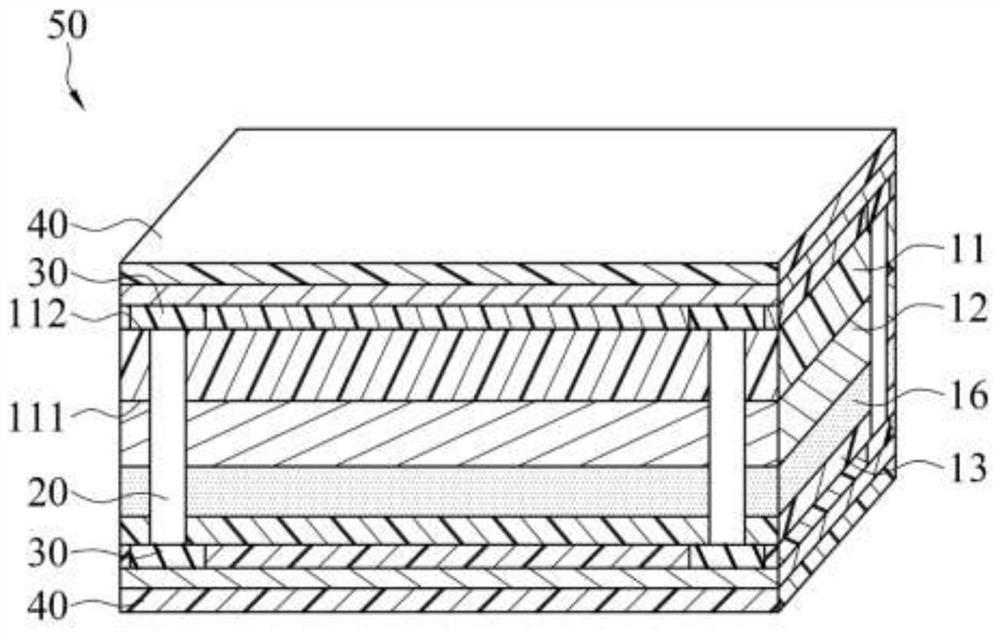

[0051] see Figure 1 to Figure 4 , is a flexible circuit board according to an embodiment of the present invention, figure 1 A schematic diagram of the appearance of a flexible circuit board according to an embodiment of the present invention, figure 2 A schematic cross-sectional view of a non-bending area of a flexible circuit board according to an embodiment of the present invention, image 3 A schematic cross-sectional view of a bending area of a flexible circuit board according to an embodiment of the present invention, Figure 4 A schematic diagram of the appearance of a flexible circuit board after multiple inversions according to an embodiment of the present invention. Such as figure 1 and Figure 4 As shown, the flexible circuit board 100 of this embodiment includes a non-bending region 10 , a plurality of pl...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap