Multilayer lattice material structure

A material structure and lattice technology, used in medical science, prosthesis, tissue regeneration, etc., can solve the problems of model surface damage, waste of materials and processing time, etc., to achieve rapid processing, avoid stress shielding, and improve porosity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

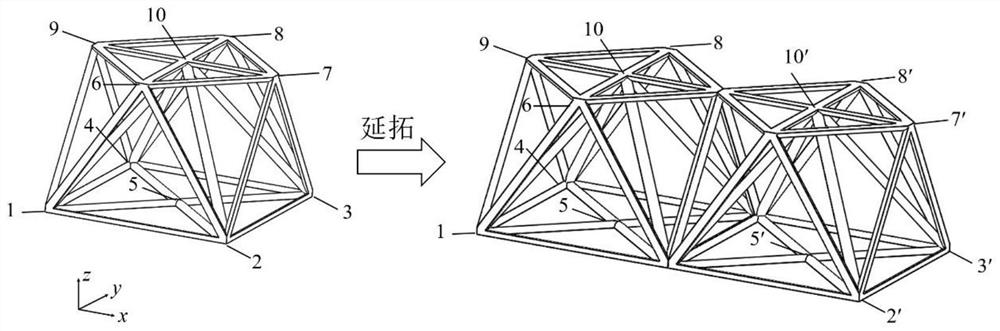

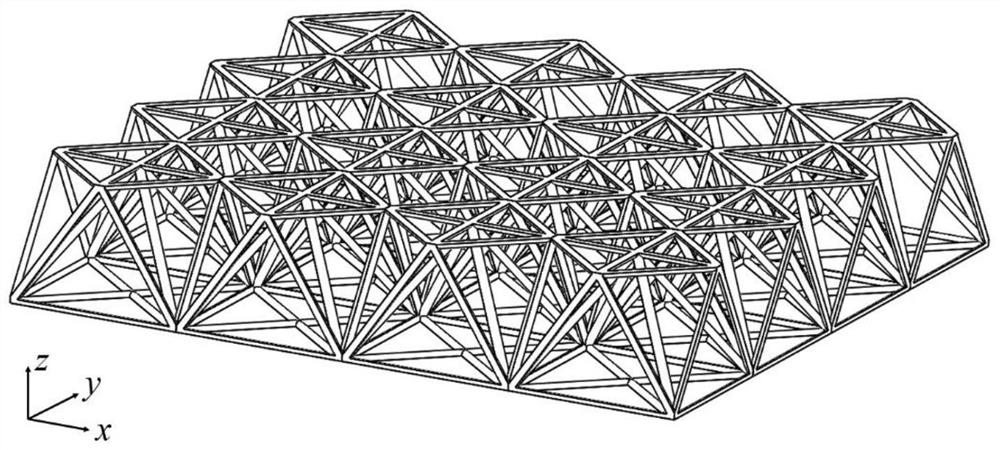

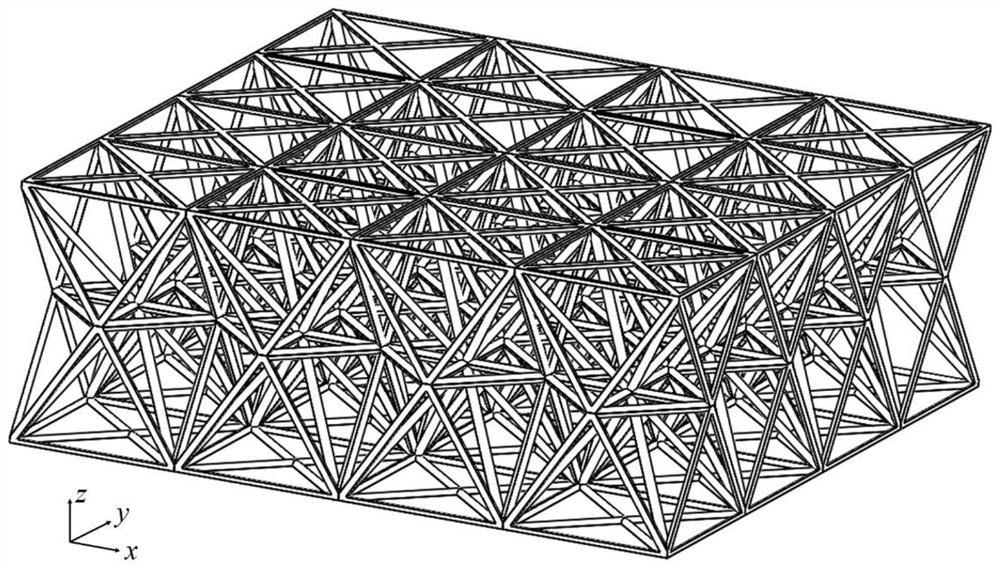

[0020] Such as figure 1 As shown, the single unit cell structure provided by the present invention can be quickly processed and manufactured by additive manufacturing technology, and the unit cell includes 4 rods, 16 semicircular rods, and 4 1 / 4 round rods. The internal rod structure of the unit cell is formed by connecting the nodes (1)-(4) respectively, and the sides of the triangle are the projections of the internal rod structure of the unit cell in four lateral directions. The bottom surface of the square is composed of bottom rods on the sides of the triangle, and the diagonals are connected by rods to improve the compressive capacity of the structure. The rhombus top surface is composed of nodes (6)-(10) connected to each other. The connection between the unit cell and the unit cell is extended along the x direction through the triangular member plane formed by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com