Plate bending device for metal product machining

A technology for metal products and bending devices, applied in the field of metal bending, can solve the problems of single practicability, unfavorable use, inconvenient adjustment of different angles of sheet metal bending, etc., and achieve the effect of preventing damage and rotating smoothly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

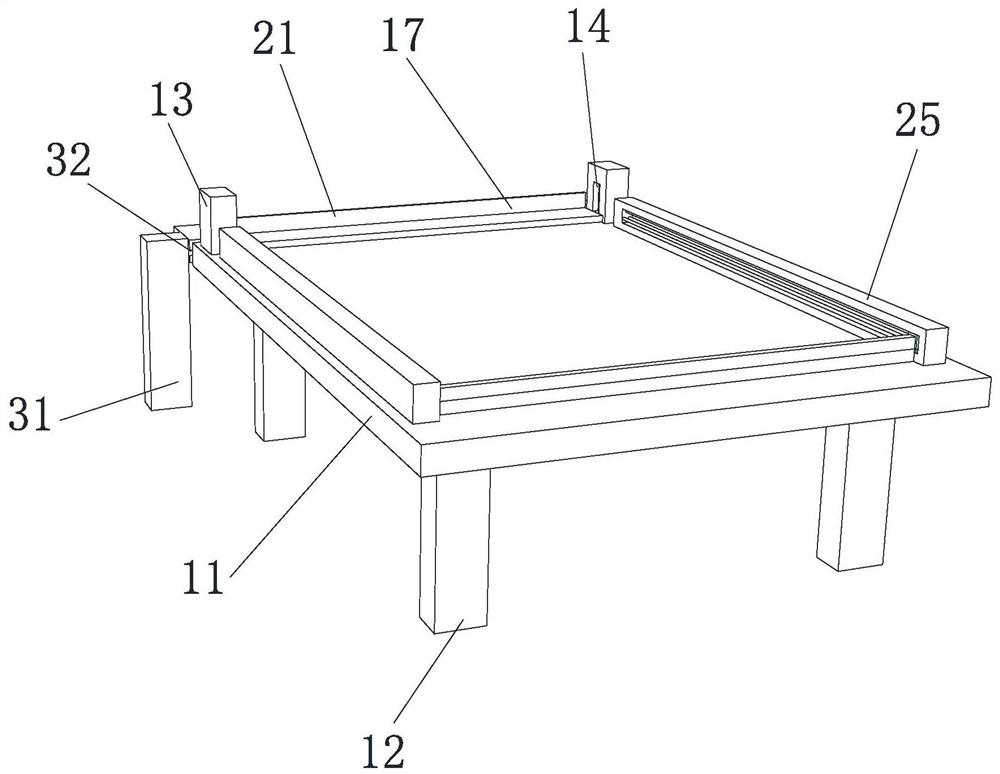

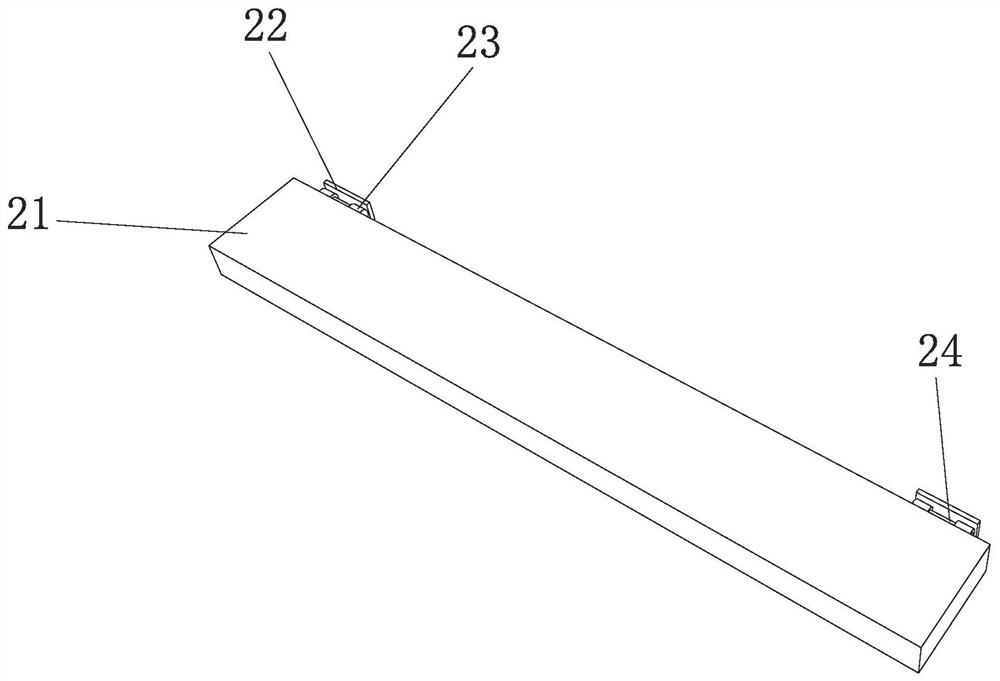

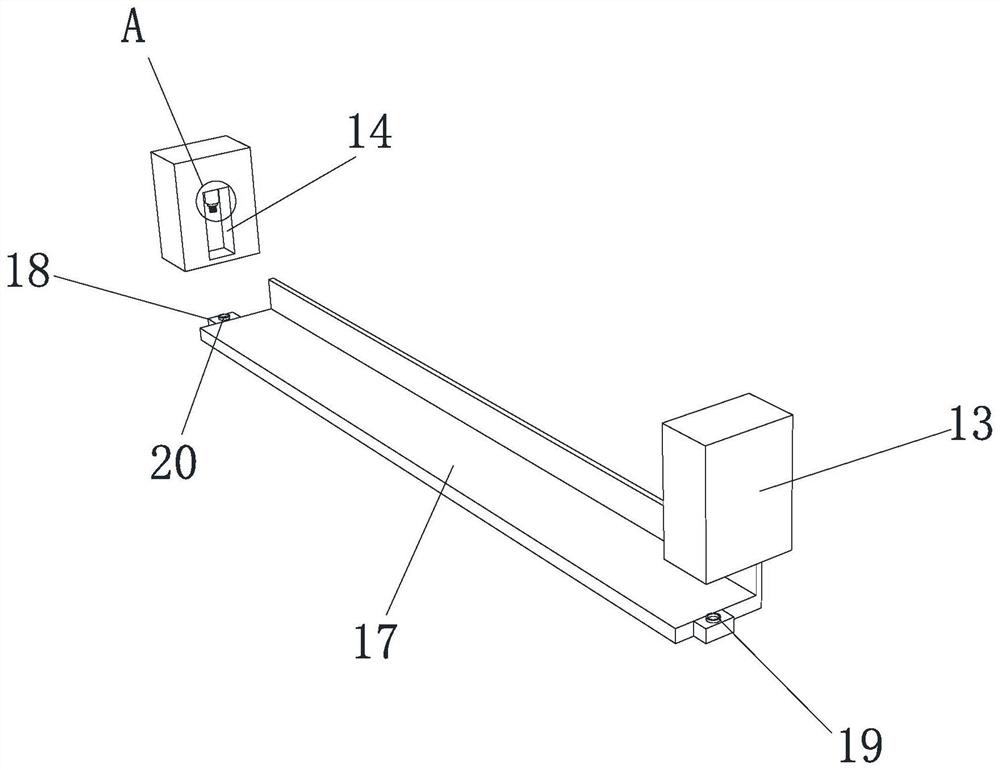

[0031] Embodiment: a kind of plate bending device for processing metal products, such as Figure 1-Figure 6As shown, it includes a plane workbench 11, the bottom end of the plane workbench 11 is fixed with equidistant evenly distributed rectangular support legs 12, the top of the plane workbench 11 is provided with two symmetrically distributed first housings 13, and the two first The opposite sides of the casing 13 are provided with a first rectangular chute 14, and the two first rectangular chute 14 inner wall tops are provided with telescopic motors 15, and the bottom ends of the two telescopic motors 15 are fixed with bolts 16. The casings 13 are all fixedly connected with L-shaped limit bending plates 17 by bolts 16, two first connectors 22 are fixed on the side walls of the planar workbench 11, and two circular rings are fixed on the side walls of the two first connectors 22. Shaped collar 23, two first connectors 22 are hinged with baffle plate 21 through four circular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com