Low-energy-consumption concrete mixing equipment

A technology for mixing equipment and concrete, which is applied in the field of low-energy concrete mixing equipment, can solve the problems of large energy consumption and energy loss, and achieve the effects of reducing energy consumption, reducing energy consumption rate, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

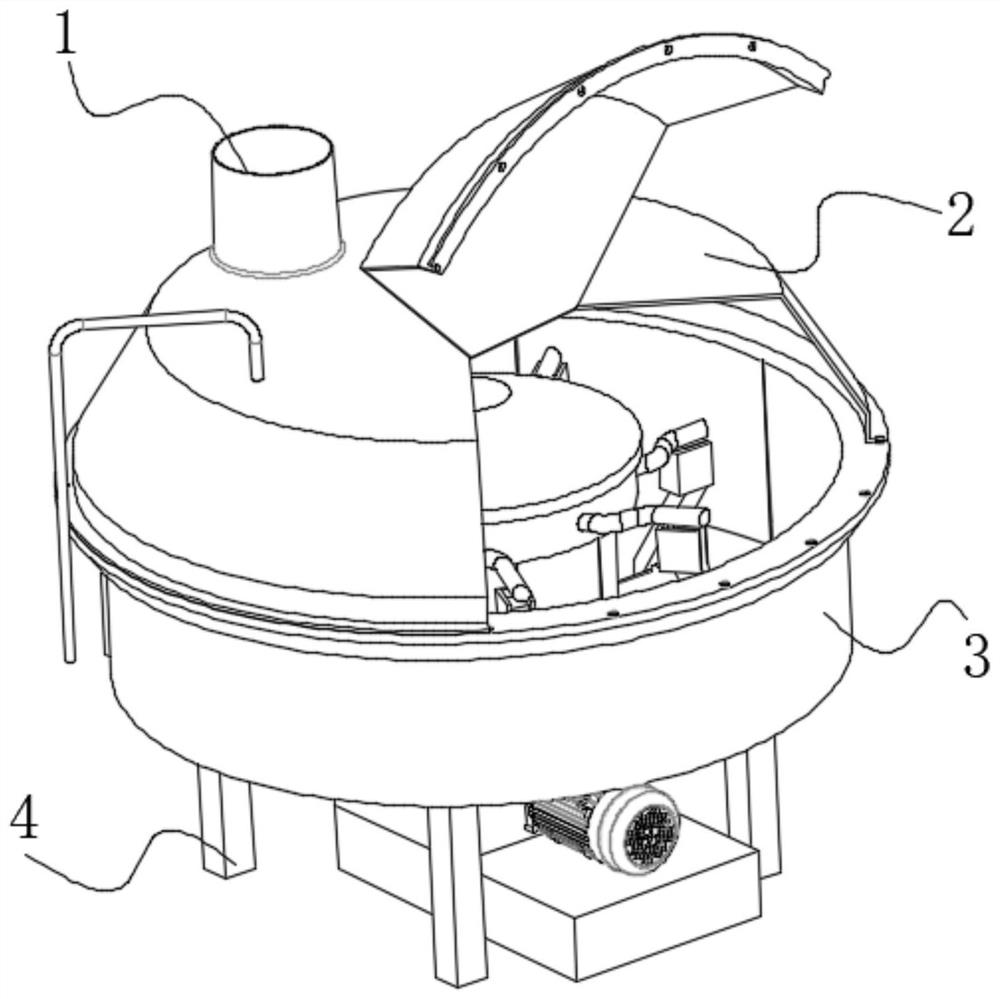

[0023] use Figure 1-Figure 7 A low energy consumption concrete mixing equipment according to an embodiment of the present invention is described as follows.

[0024] Such as Figure 1-Figure 7 As shown, a kind of low-energy concrete mixing equipment of the present invention comprises a leg 4; the top of the leg 4 is provided with a stirring tank 3, and the bottom of the top of the leg 4 is fixedly connected to the stirring tank 3, and the top of the stirring tank 3 is provided with a cover plate 2, and the top of the mixing tank 3 is fixedly connected to the bottom of the cover plate 2, the left end of the top of the cover plate 2 is provided with a feed port 1, and the top of the cover plate 2 is fixedly connected to the bottom of the feed port 1, and the legs 4 are set The purpose is to improve its stability.

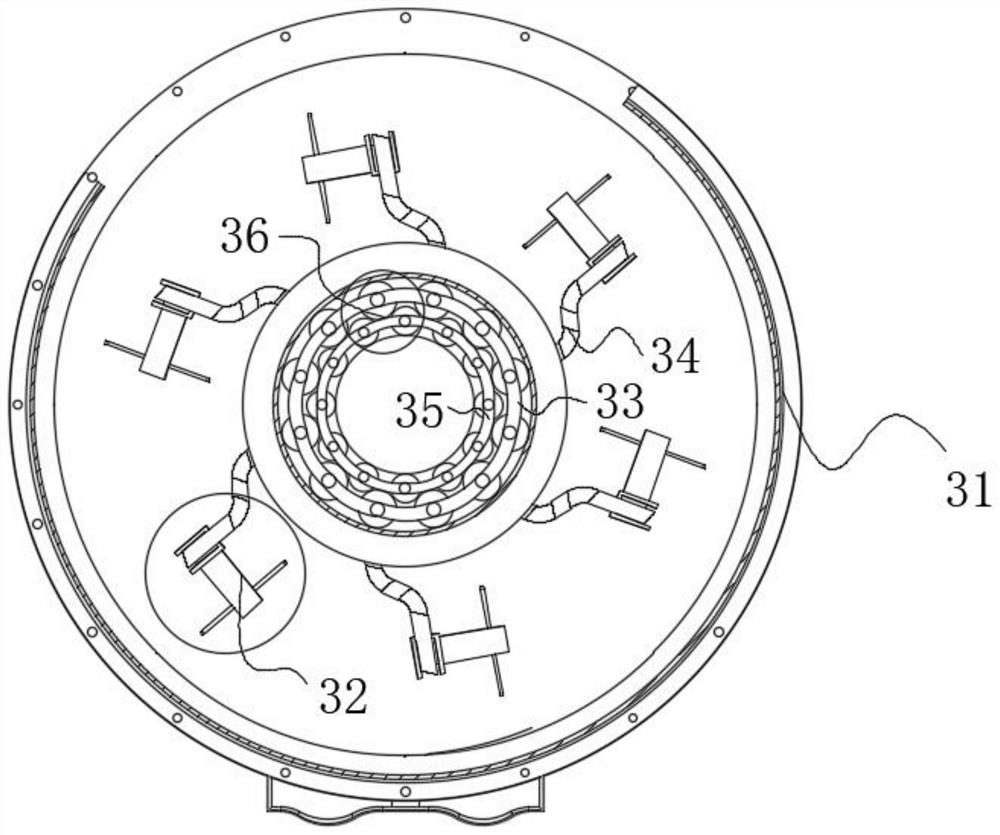

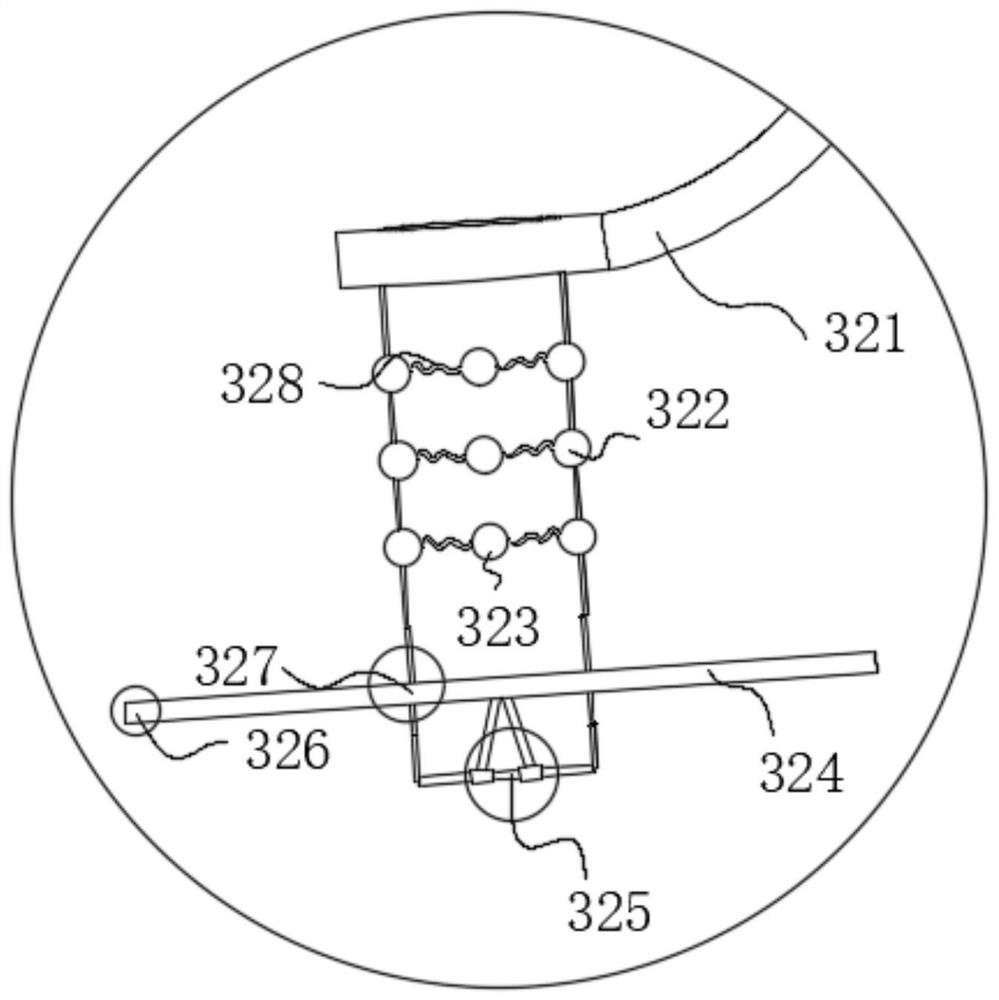

[0025] Stirring tank 3 comprises tank wall 31, and the inside of tank wall 31 is uniformly provided with stirring rod 34, and the bottom of stirring rod 34 is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com