Method capable of increasing offset printing adhesive force of edge of color box and drying device thereof

A drying device and adhesion technology, which is applied in the direction of printing devices, printing post-processing, general parts of printing machinery, etc., can solve the problems of easy fading, insufficient adhesion, no continuity, etc., achieve uniform coloring effect, enhance The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

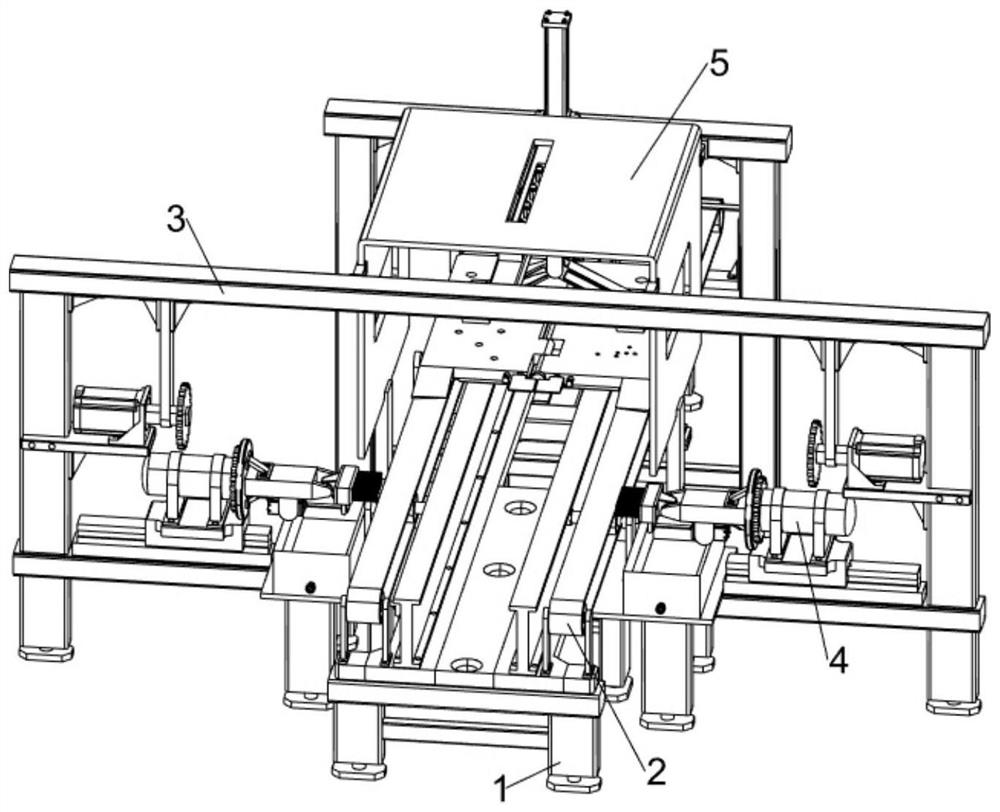

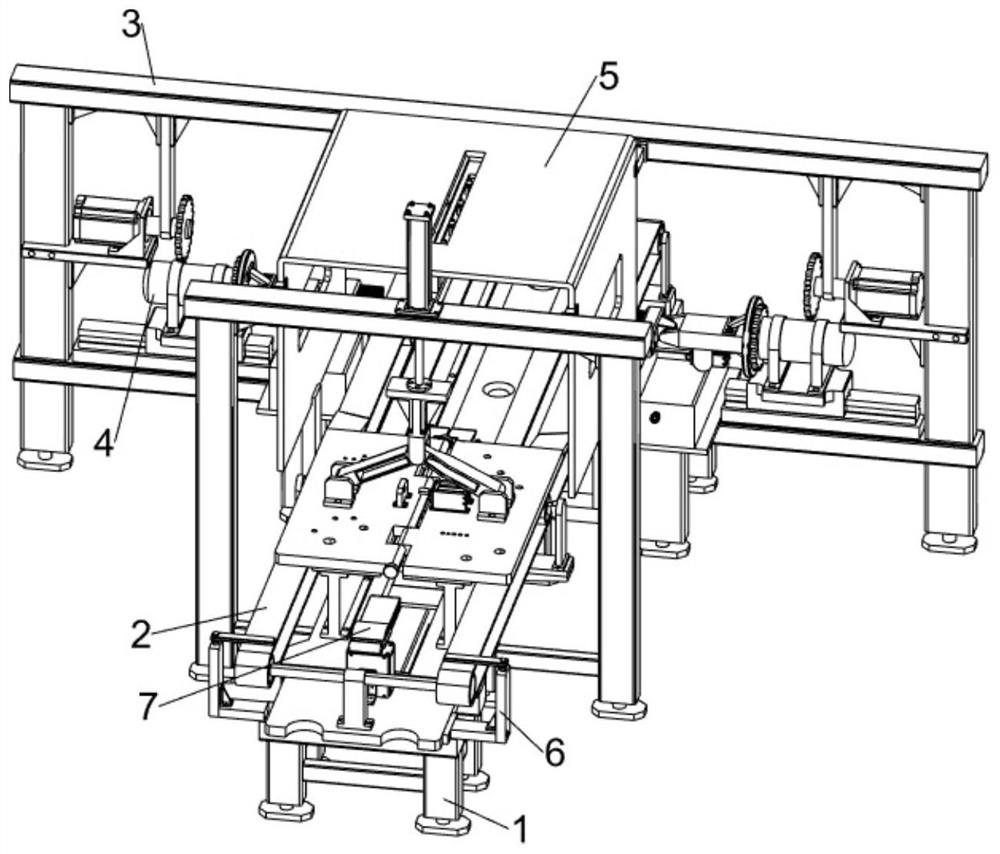

[0033] according to Figure 1-2 As shown, a drying device that can increase the adhesion of color box edge offset printing includes a support frame 1, a transmission mechanism 2, an installation frame 3, an accelerator coating system 4, and a drying system 5; the top of the support frame 1 A transmission mechanism 2 is installed on the left side and the right side of the top; an installation frame 3 is connected by bolts on the front side of the bottom of the support frame 1; an accelerator brushing system 4 is installed on the left and right parts of the installation frame 3; A drying system 5 is installed in the top middle of the rear side of the installation frame 3; the lower part of the front side of the drying system 5 is connected to the supporting frame 1.

[0034] When in use, first connect the power supply, and then place the corrugated box that has been offset printed on the front side of the top of the two transmission mechanisms 2, turn on the power, and the transmi...

Embodiment 2

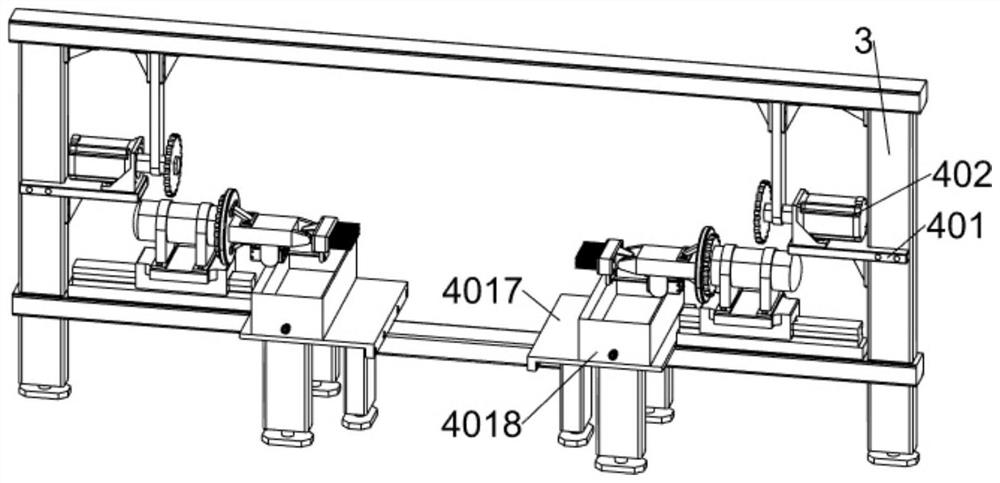

[0037] On the basis of Example 1, according to figure 1 and Figure 3-5 As shown, the accelerator painting system 4 includes a motor base plate 401, a power motor 402, a first spur gear 403, a first bearing frame plate 404 and a painting assembly; A motor seat plate 401 is connected; a power motor 402 is connected to each bolt on the top of the two motor seat plates 401; a first flat gear 403 is fixedly sleeved on the output shafts of the two power motors 402; the inner top of the installation frame 3 There is a first bearing frame plate 404 connected by bolts on the left and right sides of the left and right sides; the output shafts of the two power motors 402 pass through the first bearing frame plate 404 on both sides respectively; There is a set of painting components.

[0038] After the transmission mechanism 2 drives the corrugated box to move between the two accelerant brushing systems 4, control the power supply of the power motor 402 and start it, the power motor 40...

Embodiment 3

[0042] On the basis of embodiment 2, according to figure 1 and Figure 6-8 As shown, the drying system 5 includes a drying protective cover 501, an installation box frame 502, a drying air duct 503, a gantry frame 504, a folding assembly and an auxiliary opening assembly; Drying protective cover 501; the lower side of drying protective cover 501 is bolted to support frame 1; the inner top of drying protective cover 501 is welded with installation box frame 502; The rear side of the cover 501 is bolt-connected with a gantry frame 504; the top middle of the gantry frame 504 is equipped with a folding assembly; the front side of the folding assembly is equipped with an auxiliary expansion assembly.

[0043] The two conveying mechanisms 2 convey the corrugated cardboard box to the inside of the drying system 5 again. First, the auxiliary stretching component is inserted through the opening of the corrugated cardboard box, and then the corrugated cardboard box continues to move an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com