Glass enclosure structure with double-layer embedded pipes and operation method

An enclosure structure and outer glass technology, applied in heating methods, building components, household appliances, etc., can solve the problems of reducing the load of indoor heating and air conditioning, and achieve the goals of improving temperature and louver temperature, reducing load, and lowering temperature grade Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

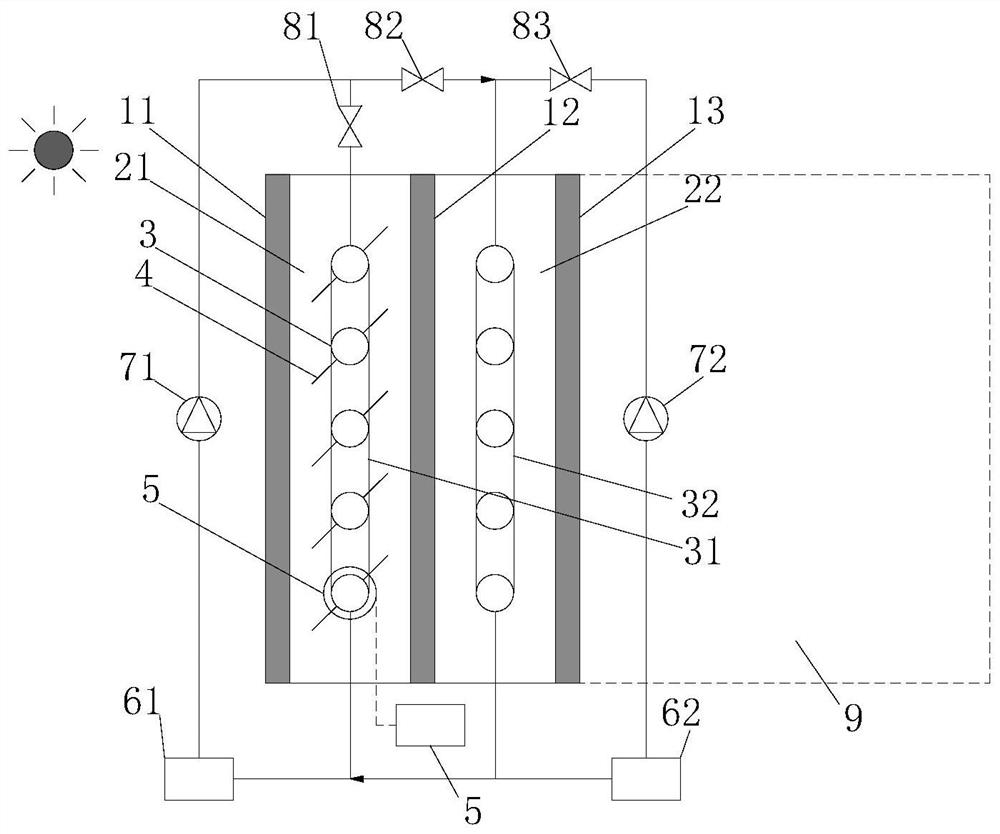

[0049] In the cold cooling, for example, the inlet water temperature set value of the outer drain pipe 31 is 30 ° C, the inlet water temperature set value of the inner water pipe 32 is 18 ° C, and the temperature from the low-grade energy source device 61 is 25 ° C, The temperature of the water from the high-grade energy device 62 is 15 ° C, and the retraction temperature difference set value of the stop operation of the two rows of water pipes is 2 ° C. At this time, the water from the low-grade energy source device 61 is introduced into the outer drain pipe 31, and the water from the high-grade energy source device 62 is introduced into the inner drain pipe 32, and the first and third cycles are operated. When an arbitrary drain is re-returned to the water temperature difference below 2 ° C, the circulating pump of the circulating loop in the drain pipe is stopped running.

[0050] Further, the inlet water temperature set value of the outer drain pipe 31 is 30 ° C, the inlet wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com