Automatic monitoring device for marine crank

An automatic monitoring and cranking technology, which is applied in the direction of combustion engine, engine control, engine components, etc., can solve the problems of response delay, high maintenance cost, and detection accuracy drop, and achieve accurate receiver position, simple device structure, and high control accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

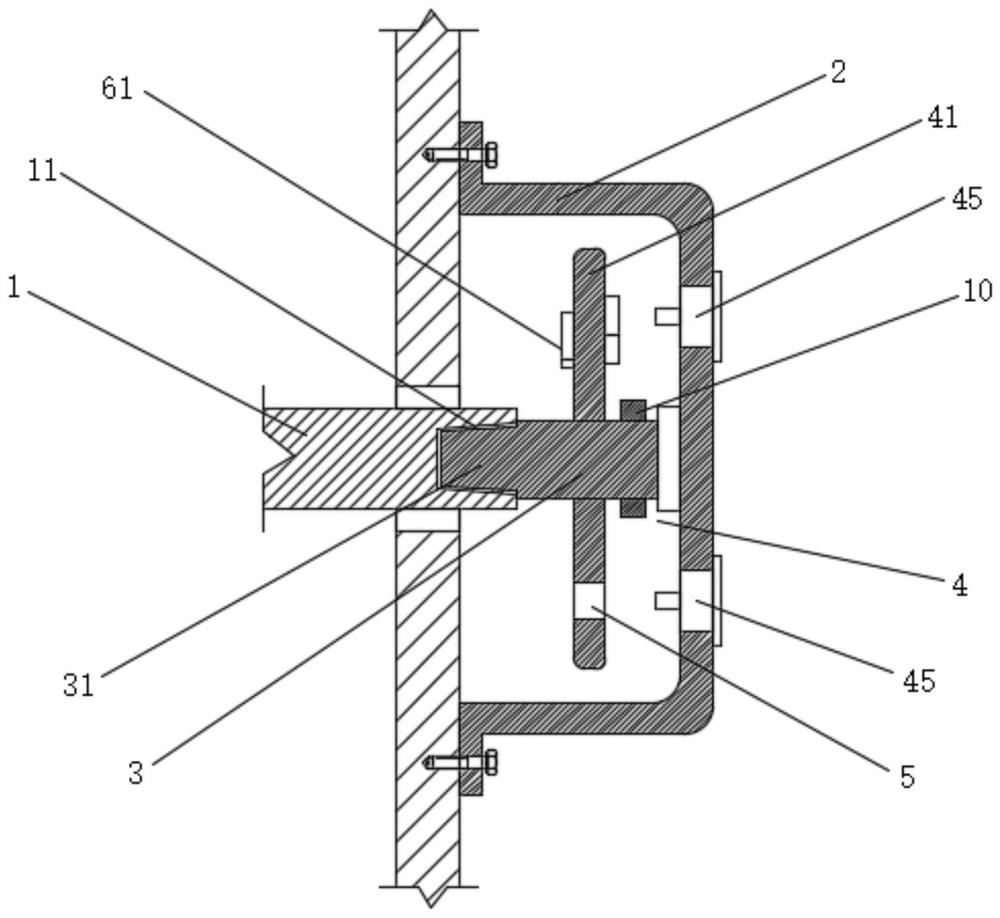

[0036] Such as Figure 1-4 As shown, a marine crank automatic monitoring device includes:

[0037] Crankshaft 1, the tail end of which extends to the outside of the machine body and a slot 11 is opened on the end surface of the tail end;

[0038] Mounting cover 2, which covers the outside of the crankshaft 1 tail end and is installed on the body; the mounting cover 2 is made of transparent plastic, the edge of the mounting cover 2 is fixed with a mounting plate, and the mounting plate can be connected to the body through screws The connection is disassembled, and the plug 31 is fully inserted into the slot 11 when the mounting plate is attached to the body;

[0039] Rotating shaft 3, one end of which is fixedly provided with a plug 31 that is engaged with the slot 11, and the other end is connected to the mounting cover 2 through a bearing. ;

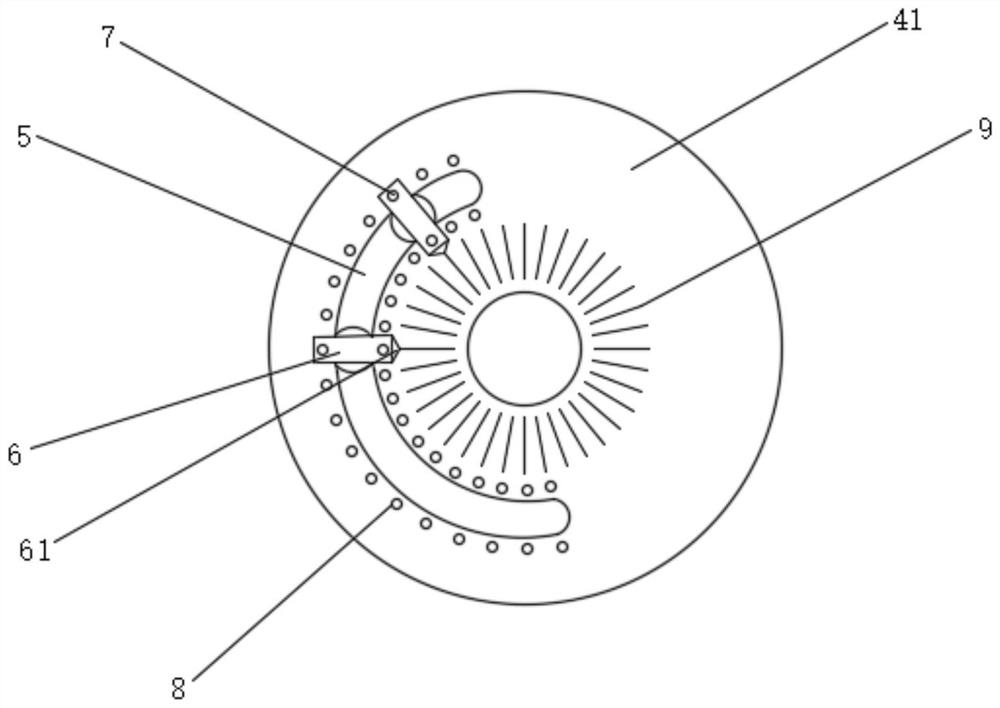

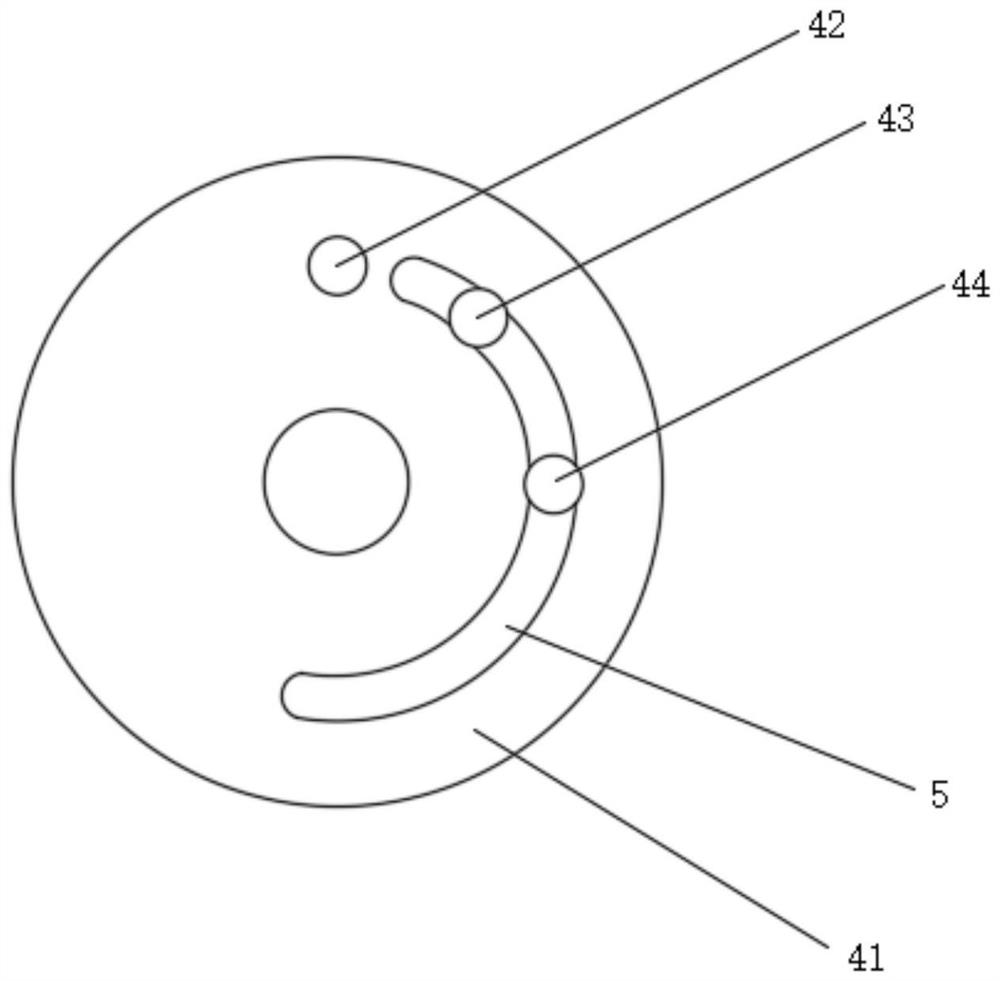

[0040] The crank monitoring assembly 4 includes a detection plate 41 fixed on the rotating shaft 3, a top dead center receiver 42 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com