Vacuum leakage inspection device based on differential pressure method

A technology of inspection device and vacuum cover, which is applied in the direction of measuring device, liquid tightness measurement using liquid/vacuum degree, fluid tightness test, etc., can solve the problems of lack of environmental lighting, large drop, large area, etc., and achieve reliable Increased performance and maintenance performance, no drop in vacuum degree, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

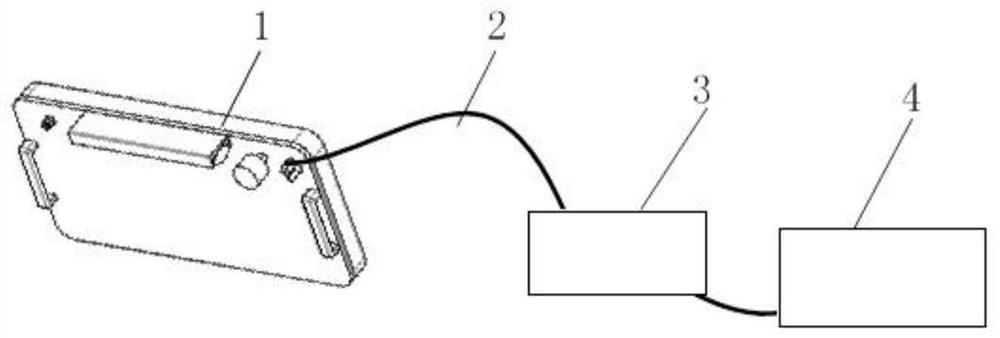

[0024] A vacuum leak detection device based on the pressure difference method, which includes a vacuum cover, a plug-in air tube, a vacuum pump and a portable lithium battery pack, the vacuum cover is connected to the vacuum pump through the plug-in air tube, and the vacuum pump is connected to the portable lithium battery pack .

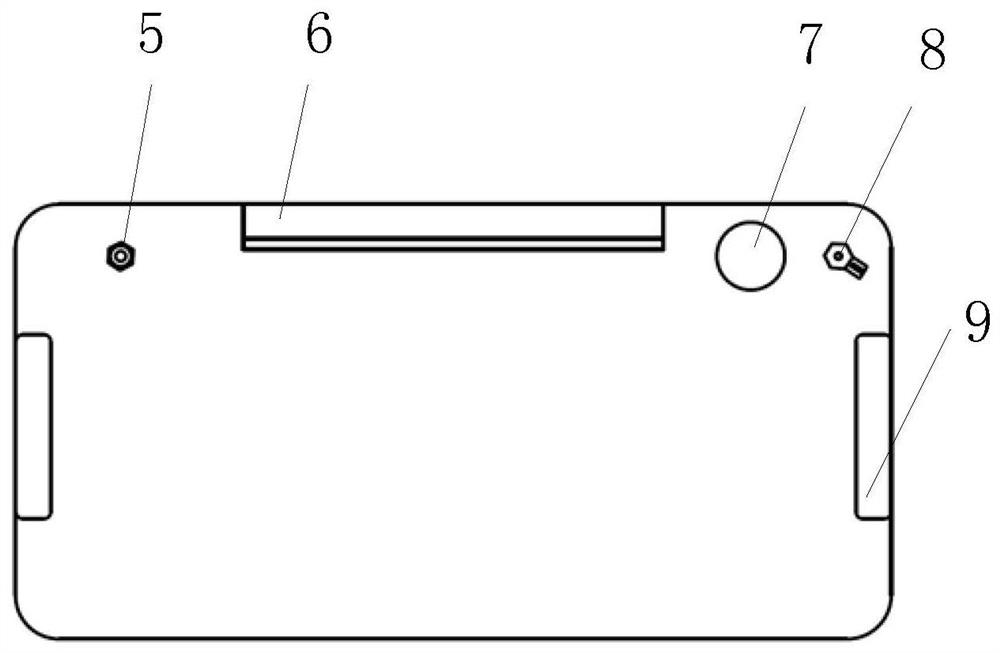

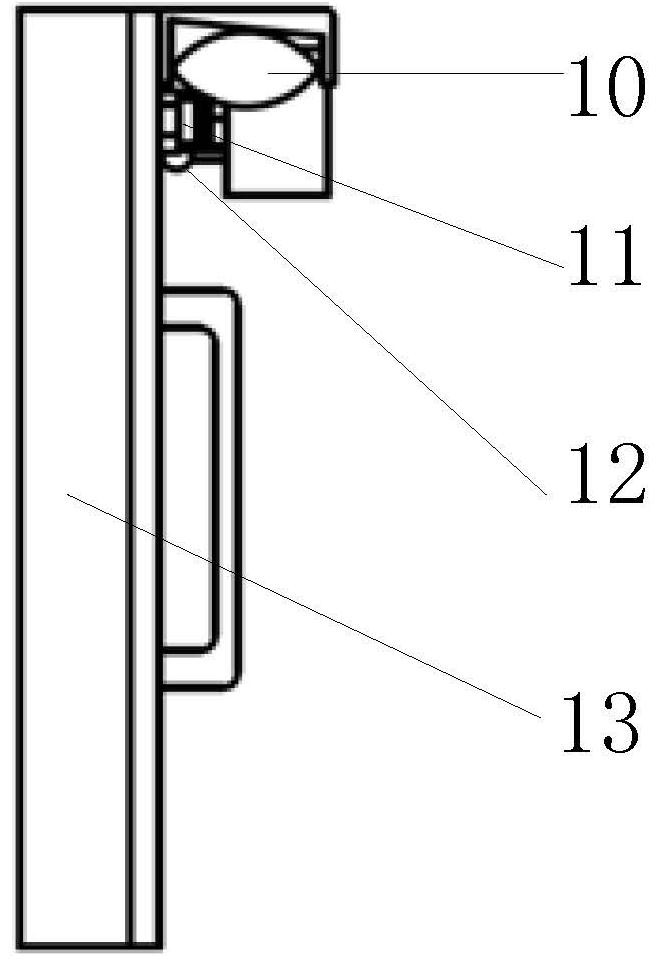

[0025] The vacuum cover includes a panel, wherein the panel of the vacuum cover is provided with a quick interface for the air pipe, the panel of the vacuum cover is fixed with a lighting support frame, the panel of the vacuum cover is fixed with a quick plug vacuum gauge, and the panel of the vacuum cover is fixed There is a regulating valve, an ergonomic handle is fixed on the panel of the vacuum cover, an adjustable nut is fixed on the panel of the vacuum cover, and a wrapping sealing strip is fixed on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com